Full-liquid air separation device using cold energy of liquefied natural gas (LNG)

A liquid air and separation device technology, applied in the direction of cold treatment separation, refrigeration and liquefaction, liquefaction, etc., can solve the problem of high power consumption per unit, and achieve the effects of saving water consumption, compact structure, and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

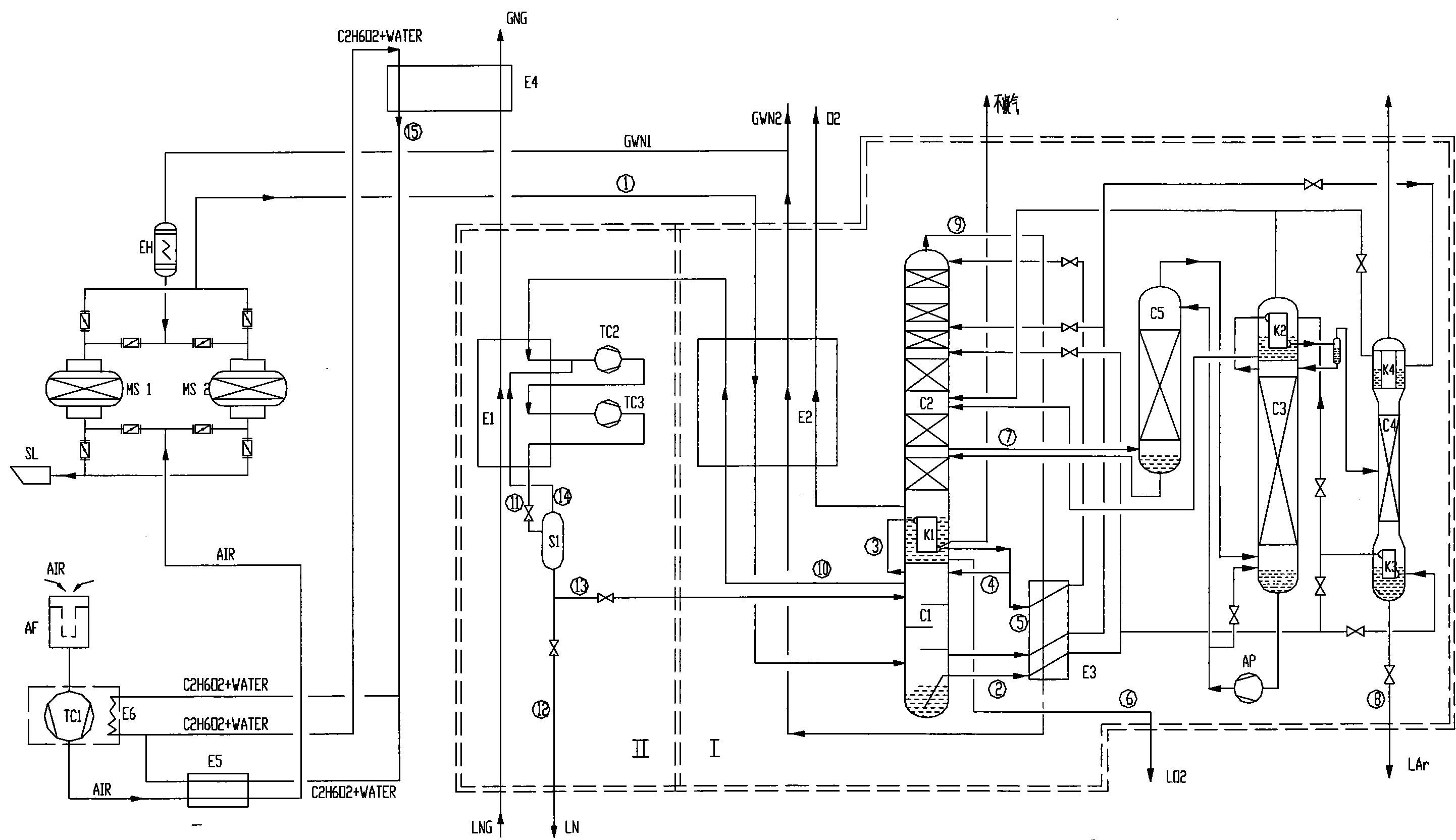

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0017] see figure 1 , the present invention is an all-liquid air separation device utilizing LNG cold energy, comprising an air compression precooling system, an air purification system, an air separation system and a nitrogen circulation system for recovering LNG cold energy.

[0018] After the raw air passes through the filter AF to filter out dust and impurities, it enters the air compressor TC1 and is compressed to about 0.52Mpa, and is cooled by the refrigerant (ethylene glycol aqueous solution or Freon) in the intercooler E6 and final cooler E5 of the air compressor TC1 ) to pre-cool to about 5°C, and then enter the purification system to remove moisture, carbon dioxide and other impurities in the air through adsorption device MS1 or ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com