Fixed type multi-layered vacuum heat-insulating high-pressure liquid hydrogen storage tank

A vacuum adiabatic and high-pressure liquid technology, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, hydrogen technology, etc., can solve the problems of increasing hydrogen storage pressure, hydrogen energy waste, limiting applications, etc., to reduce evaporation , avoid waste and prevent overpressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

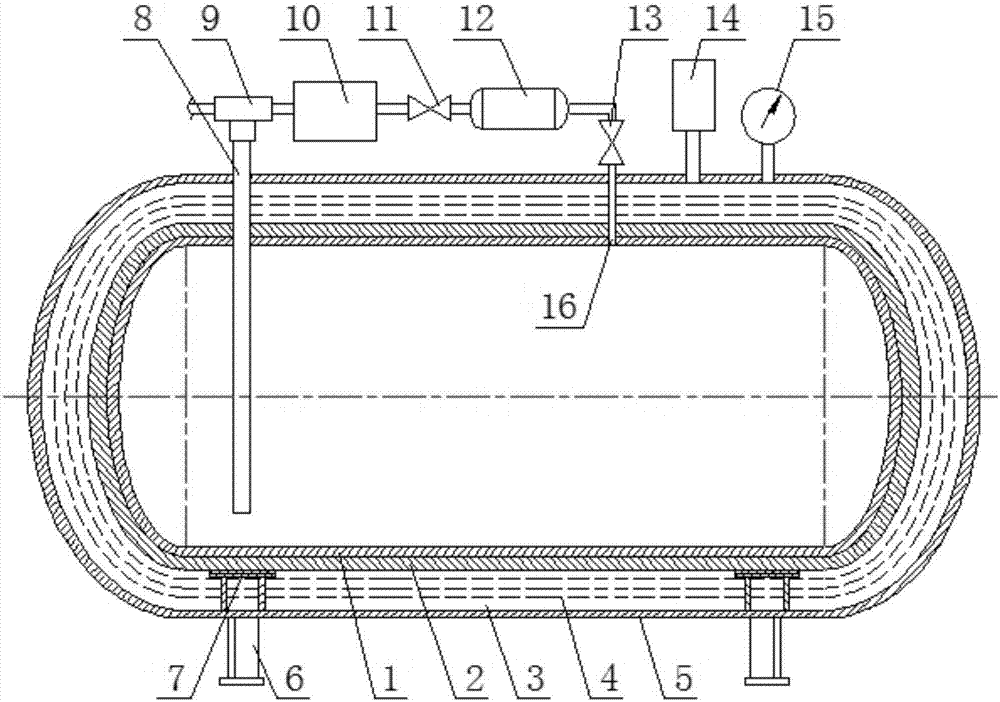

[0021] Such as figure 1 As shown, the fixed multi-layer vacuum insulated high-pressure liquid hydrogen storage tank consists of two parts: the inner tank 1 and the outer tank 5. The tank body containing liquid hydrogen is used as the inner tank 1, and the outer shell is wrapped with a layer of fiber-reinforced epoxy resin-based composite material. 2, and is fixed in the cavity of the outer tank 5 by at least two inner tank supports 7; the cavity between the inner tank 1 and the outer tank 5 is a vacuum insulation interlayer 3, and multiple layers are laid in the vacuum insulation interlayer 3 for The vacuum radiation protection insulation layer 4 covering the entire inner tank 1; the outer tank 5 is provided with a vacuum pumping device 14 and a vacuum gauge 15 communicating with the vacuum insulation interlayer 3;

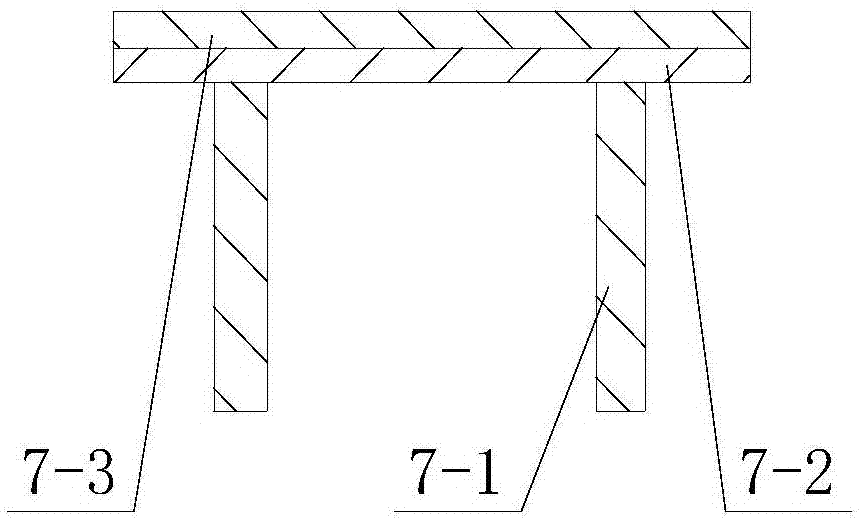

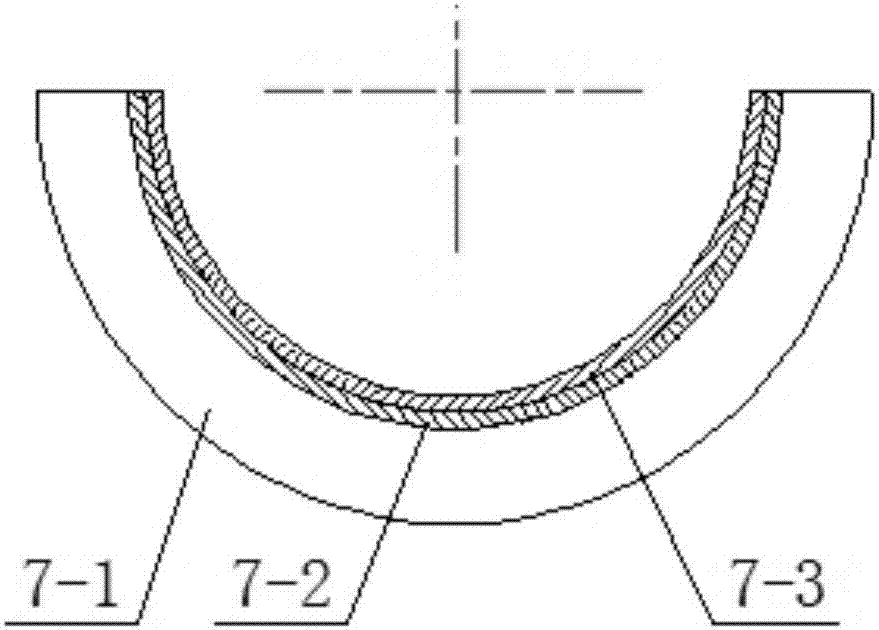

[0022] The inner tank support member 7 includes an annular rib 7-1, and a metal backing plate 7-2 and a non-metal backing plate 7-3 are arranged around the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com