E-cigarette personal vaporizer

a vapourizer and electronic technology, applied in the direction of tobacco, instruments, packaged goods, etc., can solve the problems of insufficient recharging of pvs, insufficient cigalites, and ineffective e-liquid pvs, so as to reduce consumption, reduce consumption, and be easily and quickly replaced by users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

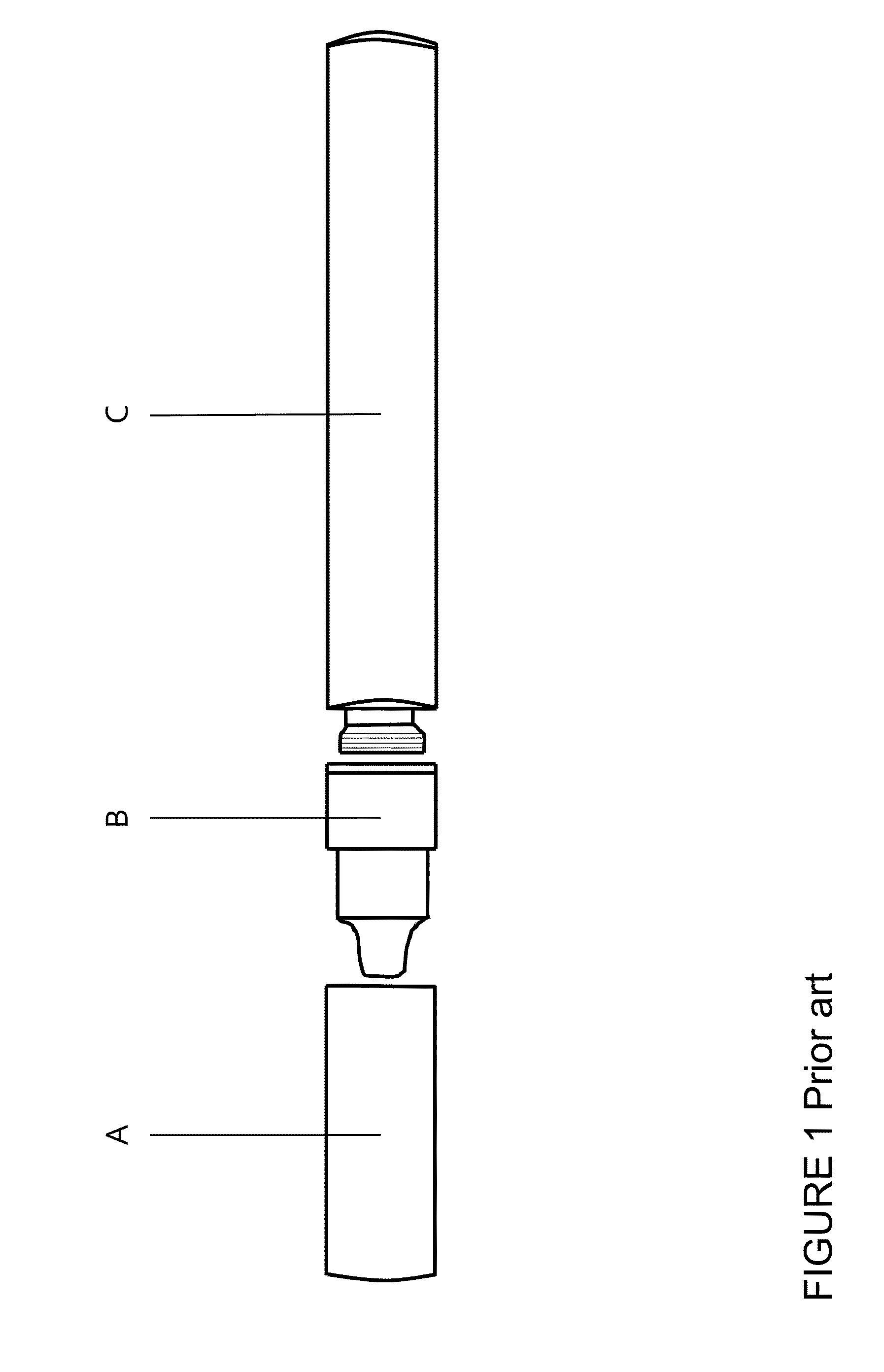

[0235]FIG. 1 shows a conventional personal vapouriser (‘PV’). The PV includes the following key components: a ‘juice’ or ‘e-liquid’ delivery and container system, called a cartridge (A), and an atomizer (B) for vapourising the juice, and a power source (C) to power the atomiser. The cartridge also forms the mouthpiece. A typical design, as shown in FIG. 1, requires the battery (C) to be screwed into the atomiser (B), and the cartridge (A) is then pushed onto the free end of the atomiser B. When the cartridge is fully consumed, the user discards the used cartridge and replaces it with a new one. An alternative design sees the cartridge as user-refillable, typically from a small bottle of e-liquid.

[0236]Conventional PV designs suffer a number of drawbacks. This Detailed Description section describes a number of high-level features which address the most significant drawbacks. An implementation of this invention uses one or more of these high level features.

[0237]We will organise our d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| voltages | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com