Liquid anti-caking agent for compound fertilizer

An anti-caking agent and compound fertilizer technology, applied in fertilization equipment, fertilizer mixture, application, etc., can solve problems such as crop germination, root system damage, withering, serious death, water quality and environmental pollution, etc., and achieve anti-caking effect Improve and overcome oil pollution and solve the effect of easy caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

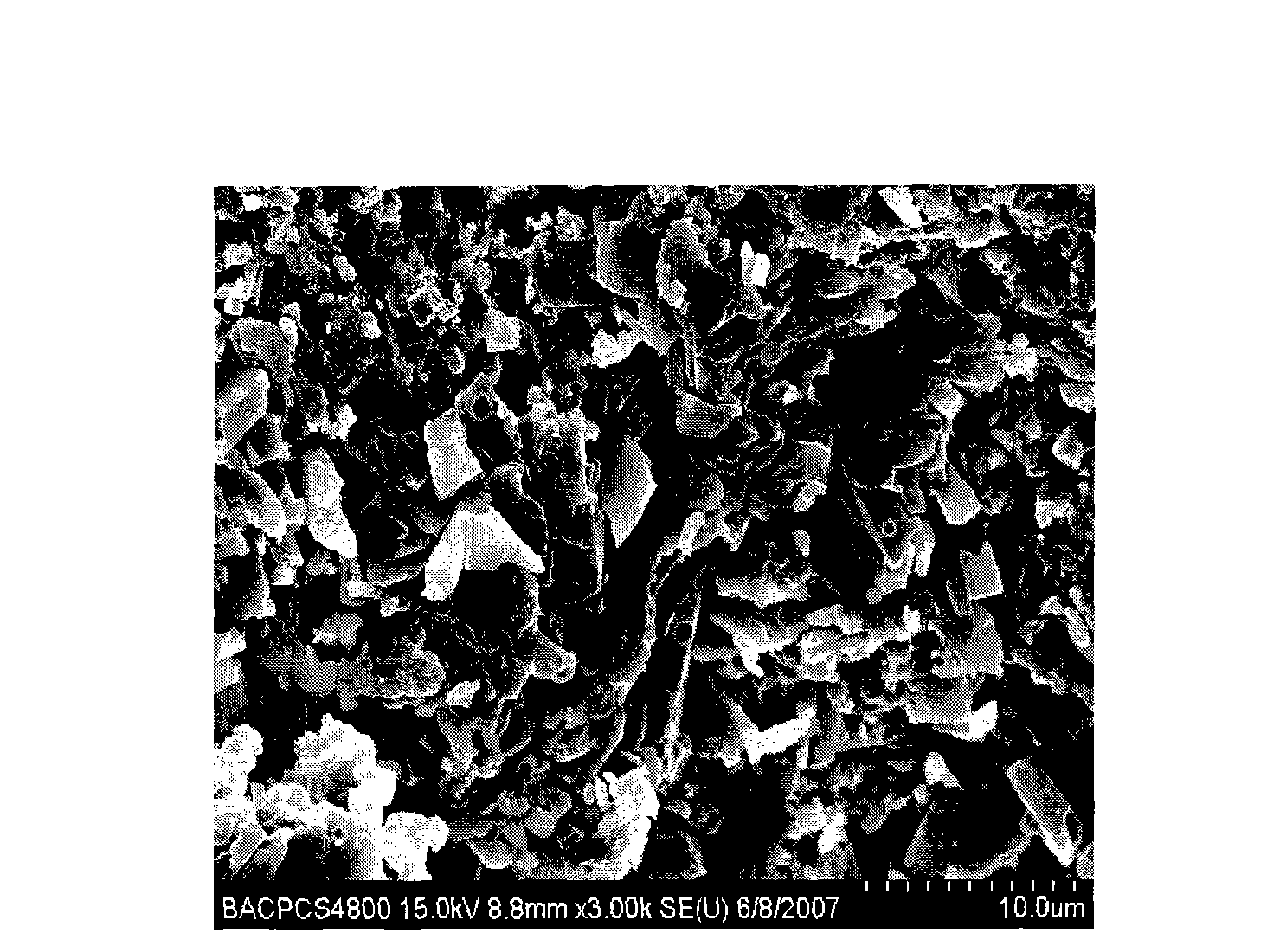

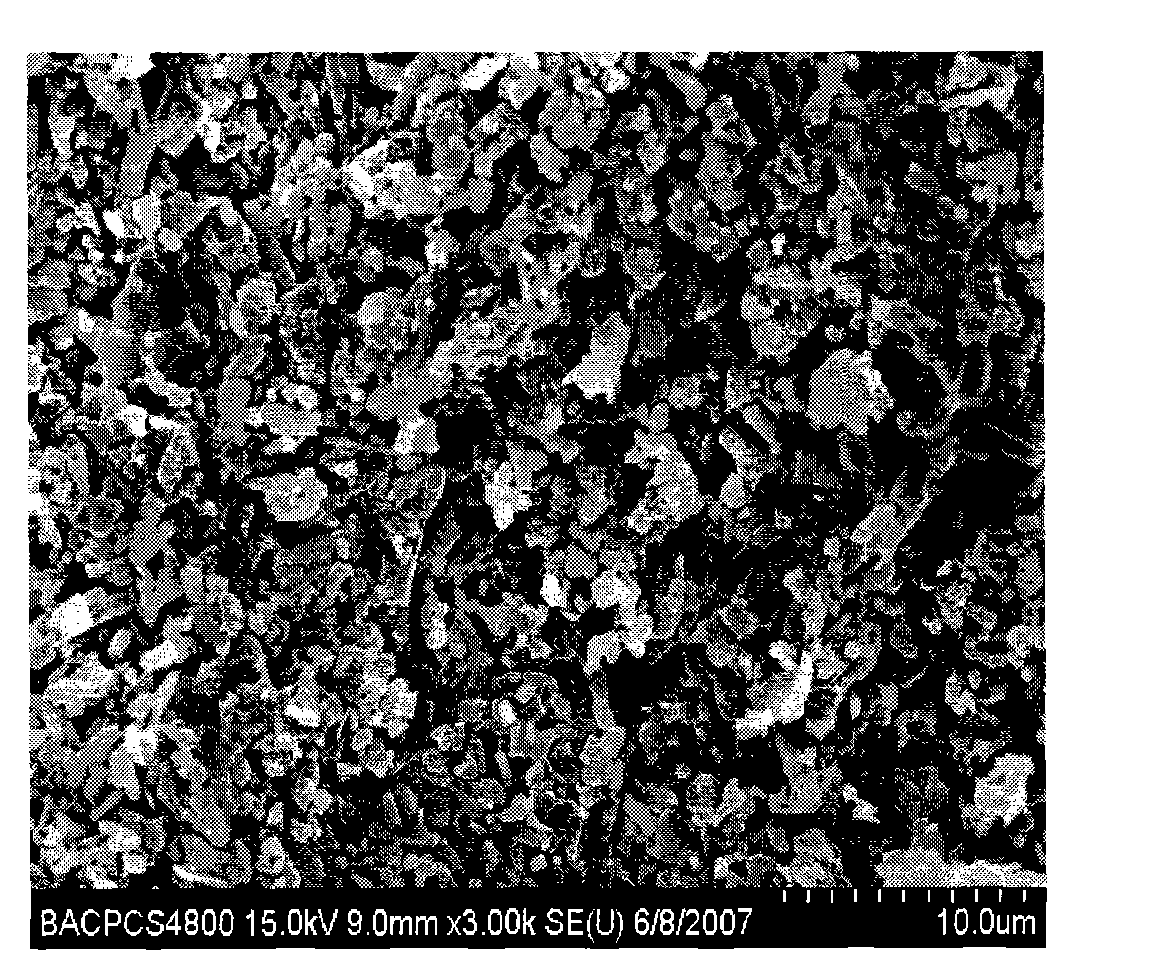

Image

Examples

Embodiment 1

[0031] Add about 30000 sodium polyacrylate aqueous solution 1mL of solid content 30wt% average molecular weight Mw (weight average molecular weight) in 60mL water, 30wt% molecular weight Mw about 30000 polysodium methacrylate 1mL, polyvinylpyrrolidone 0.4g, dodecyl naphthalene Sodium sulfonate 8g, sodium α-alkenyl sulfonate 5g, polyoxyethylene sorbitan fatty acid ester (T-40) 10g, octylphenol polyoxyethylene ether 4.5g, fatty alcohol polyoxyethylene ether (AEO- 7) 2.5 g.

[0032] After dissolving, dilute to 100mL with water and stir evenly to make a liquid anti-caking agent for compound fertilizer. Weigh 0.15g of this anti-caking agent and apply it evenly on 100g, N-P 2 o 5 -K 2 O on the compound fertilizer with a mass ratio of 30-5-5, stir and mix evenly, and let it dry, then put it in a moisture absorption device to absorb moisture for 10 hours, put the compound fertilizer into a sealed bag, and heat it in an oven at 70°C After 72 hours, take it out and let it cool at ro...

Embodiment 2

[0038] Add 29 g of polyethylene glycol with a molecular weight of 12,000 to 15,000, 0.3 g of hydroxyethyl cellulose substituted with hydroxyethyl (MS 1.8), and 0.2 g of methyl cellulose (degree of substitution 2.0, molecular weight about 90,000) into 67 mL of water. Sorbitan oleate polyoxyethylene ether 1g, ethylene glycol distearate 1g, cetyltrimethylammonium chloride (1631 chlorine type) 1.8g, alkyl glucoside (50%) 0.5g, Octadecyltrimethylammonium chloride (1831) 2.4g.

[0039] After dissolving, dilute to 100mL with water and stir evenly to make a liquid anti-caking agent for compound fertilizer. Weigh 0.15g of this anti-caking agent and apply it evenly on 100g, N-P 2 o 5 -K 2 O on the compound fertilizer with a mass ratio of 28-10-10, stir and mix evenly, and make it dry, then put it in a moisture absorption device to absorb moisture for 10 hours, then put the compound fertilizer into a sealed bag, and heat it in an oven at 70°C After 72 hours, take it out and let it co...

Embodiment 3

[0045]Add 10g of urea-formaldehyde resin with an average molecular weight of about 10000 to 55mL of water, 4.2g of polyoxyethylene-polyoxypropylene block copolymer, 1.3g of hydroxyethyl cellulose (MS1.8), 2.1g of C12-C18 fatty alcohol sodium sulfate, C8~C18 fatty alcohol sulfate triethanolamine salt 3.2g, polyoxyethylene (15) lauryl ether 4.2g, sorbitan fatty acid ester 5.1g, sodium xylene sulfonate 4.1g, sodium oleate 4.0g, octanol 0.2g, 0.4g of hydroxyl silicone oil, 1.0g of salicylic acid, 0.5g of phenol.

[0046] After dissolving, dilute to 100mL with water and stir evenly to make a liquid anti-caking agent for compound fertilizer. Weigh 0.15g of this anti-caking agent and apply it evenly on 100g, N-P 2 O 5 -K 2 O on the compound fertilizer with a mass ratio of 28-12-10, stir and mix evenly, and make it dry, then put it in a moisture absorption device to absorb moisture for 10 hours, then put the compound fertilizer into a sealed bag, and heat it in an oven at 70°C Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com