Deep deoxidizing agent and method for copper melt

A technology of deep deoxidation and melt, applied in the field of deep deoxidizer and deoxidation of copper melt, can solve the problems of reducing copper conductivity and corrosion performance, adverse effects of copper performance, copper hydrogen-induced cracks, etc., to achieve the best deoxidation effect, improve Comprehensive performance, the effect of reducing the burning loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 Oxygen content is the deep deoxidation of the copper melt of 33ppm

[0047] A kind of deoxidizer and deoxidation method for copper melt,

[0048] The specific steps are as follows: using cathode electrolytic copper as raw material, using a vacuum melting furnace and a graphite crucible to melt 9.81 kg of copper material at 1220°C. Add a phosphorus-bronze master alloy with a phosphorus content of 9% for pre-deoxidation for 25 minutes, and use a direct-reading spectrometer to detect before the furnace, and the oxygen content of the copper melt is measured to be 33ppm.

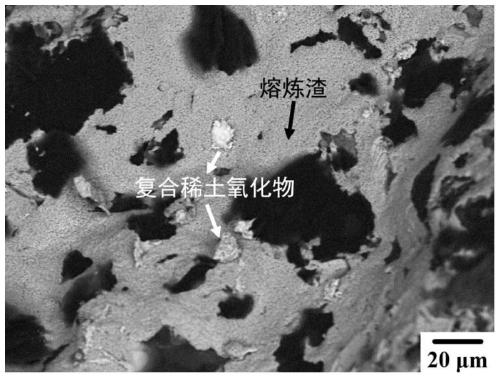

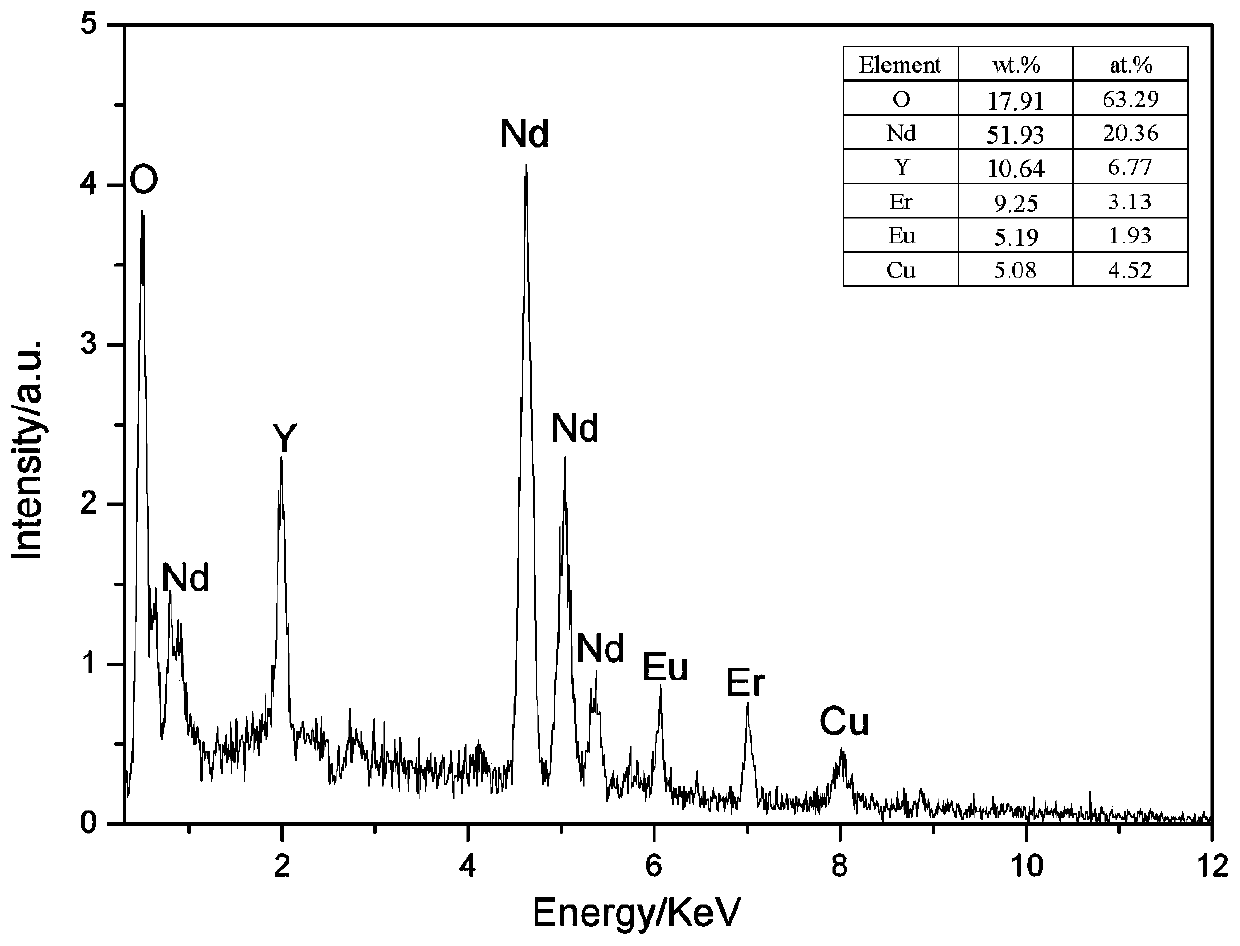

[0049] Weigh 0.88g of the deep deoxidizer after ball milling, wherein by weight percentage, neodymium is 3.66%, yttrium is 1.02%, erbium is 0.78%, and europium is 0.54%. And wrap it with copper foil and add it to the copper liquid. After adding it, use a graphite rod to stir quickly for 29 minutes, and then use a slag scoop to remove the slag. The molten copper after slag treatment was left ...

Embodiment 2

[0052] Embodiment 2 Oxygen content is the deep deoxidation of the copper melt of 50ppm

[0053] A method for deep deoxidation of copper melt,

[0054] The specific steps are as follows: using cathode electrolytic copper as raw material, using a vacuum melting furnace and a graphite crucible to melt 9.96 kg of copper material at 1150°C. Add phosphor-bronze master alloy containing 6% phosphorus for pre-deoxidation for 14 minutes, and use a direct-reading spectrometer to detect before the furnace, and the oxygen content of the copper melt is measured to be 50ppm.

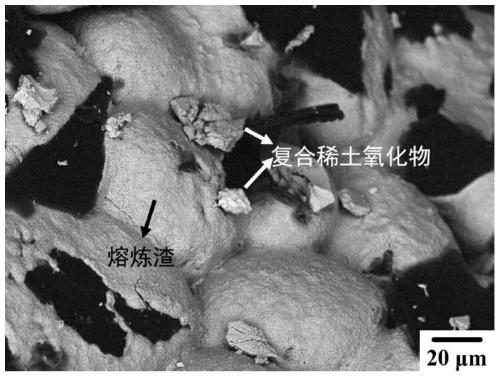

[0055] Weigh 3.29g of the deep deoxidizer after ball milling, wherein by weight percentage, neodymium is 4.8%, yttrium is 0.8%, erbium is 2%, and europium is 0.4%. And wrap it with copper foil and add it to the copper liquid. After adding, use a graphite rod to stir quickly for 25 minutes, and then use a slag scoop to remove the slag. The molten copper after the slag treatment was left to stand for 52 minutes, and th...

Embodiment 3

[0058] Embodiment 3 Oxygen content is the deep deoxidation of the copper melt of 50ppm

[0059] A method for deep deoxidation of copper melt,

[0060] The specific steps are as follows: using cathode electrolytic copper as raw material, using a vacuum melting furnace and a graphite crucible to melt 9.77 kg of copper at 1220°C. Add phosphor-bronze master alloy containing 7% phosphorus for pre-deoxidation for 17 minutes, and use a direct-reading spectrometer to detect before the furnace, and the oxygen content of the copper melt is measured to be 50ppm.

[0061] Weigh 4.23g of the deep deoxidizer after ball milling, wherein by weight percentage, neodymium is 6.2%, yttrium is 1.5%, erbium is 1.9%, and europium is 0.4%. And wrap it with copper foil and add it to the copper liquid. After adding, use a graphite rod to stir quickly for 27 minutes, and then use a slag scoop to remove the slag. After the slag treatment, the molten copper was left to stand for 54 minutes, and then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com