Device and method for continuously removing dissolved oxygen in fuel oil

A technology for dissolved oxygen and fuel oil, which is applied in separation methods, chemical instruments and methods, and treatment of hydrocarbon oil, etc. It can solve the problems of insufficient contact area, difficulty, foam generation, etc., and achieve the effect of increasing the contact surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

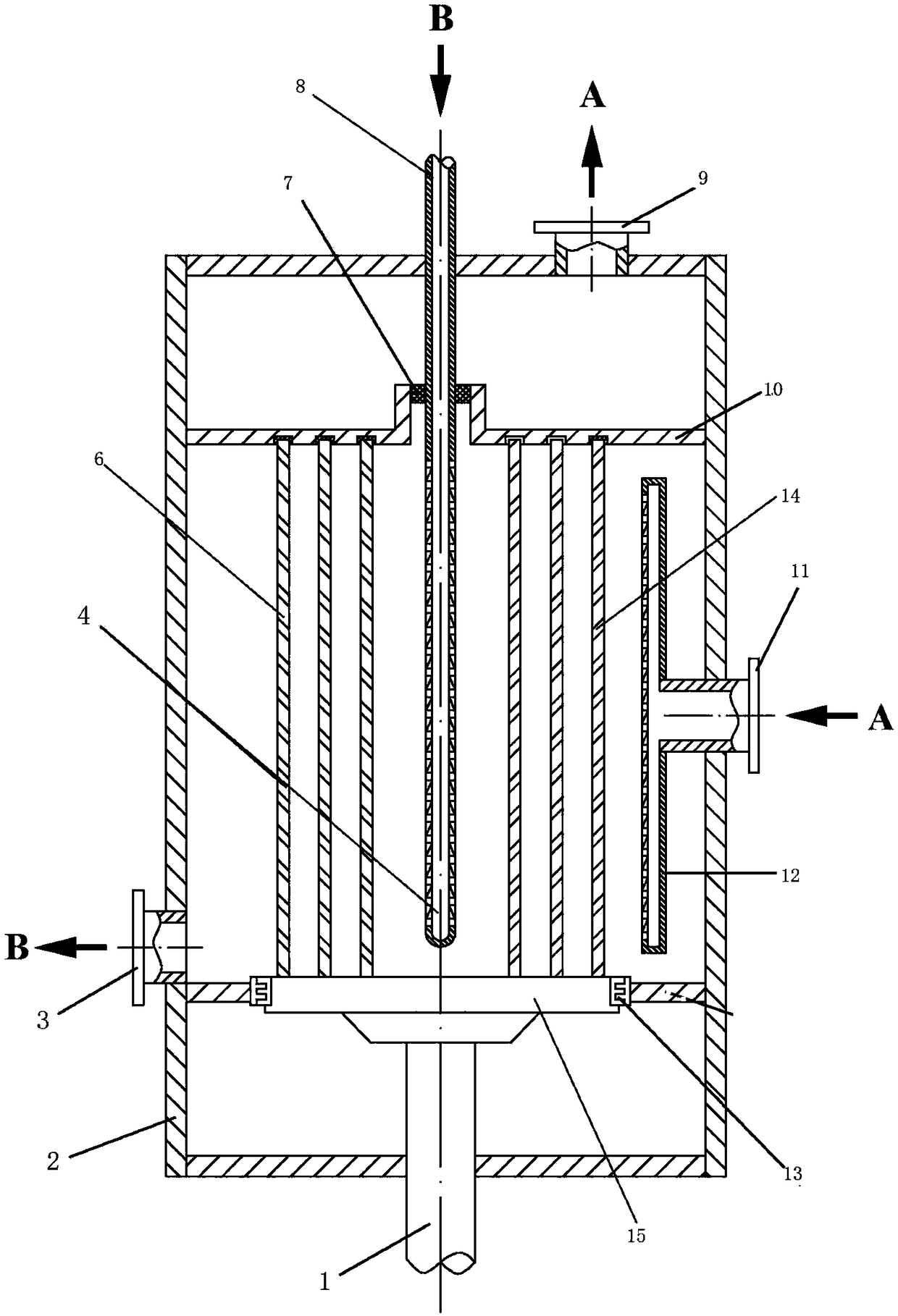

[0051] Embodiment 1: using the device of the present invention, the device has no static ring gap cylinder, and the moving ring gap cylinder is arranged concentrically in 3, such as figure 1 shown. The flow rate of aviation kerosene RP-3 is 1ml / s, the thickness of lipophilic dispersed packing is 100mm, the inlet oil temperature is room temperature, and the oxygen content is 70ppm; the rotating shaft speed is 500r / min, the system gauge pressure is 0.1MPa, and the nitrogen ventilation rate is 100ml / s, ventilation time is 15min. Results: The oxygen content of aviation kerosene RP-3 at the drain was 8ppb.

Embodiment 2

[0052] Embodiment 2: The conditions are the same as in Embodiment 1, and the oxygen-free gas is carbon dioxide gas. Results: The oxygen content of aviation kerosene RP-3 at the drain was 7ppb.

Embodiment 3

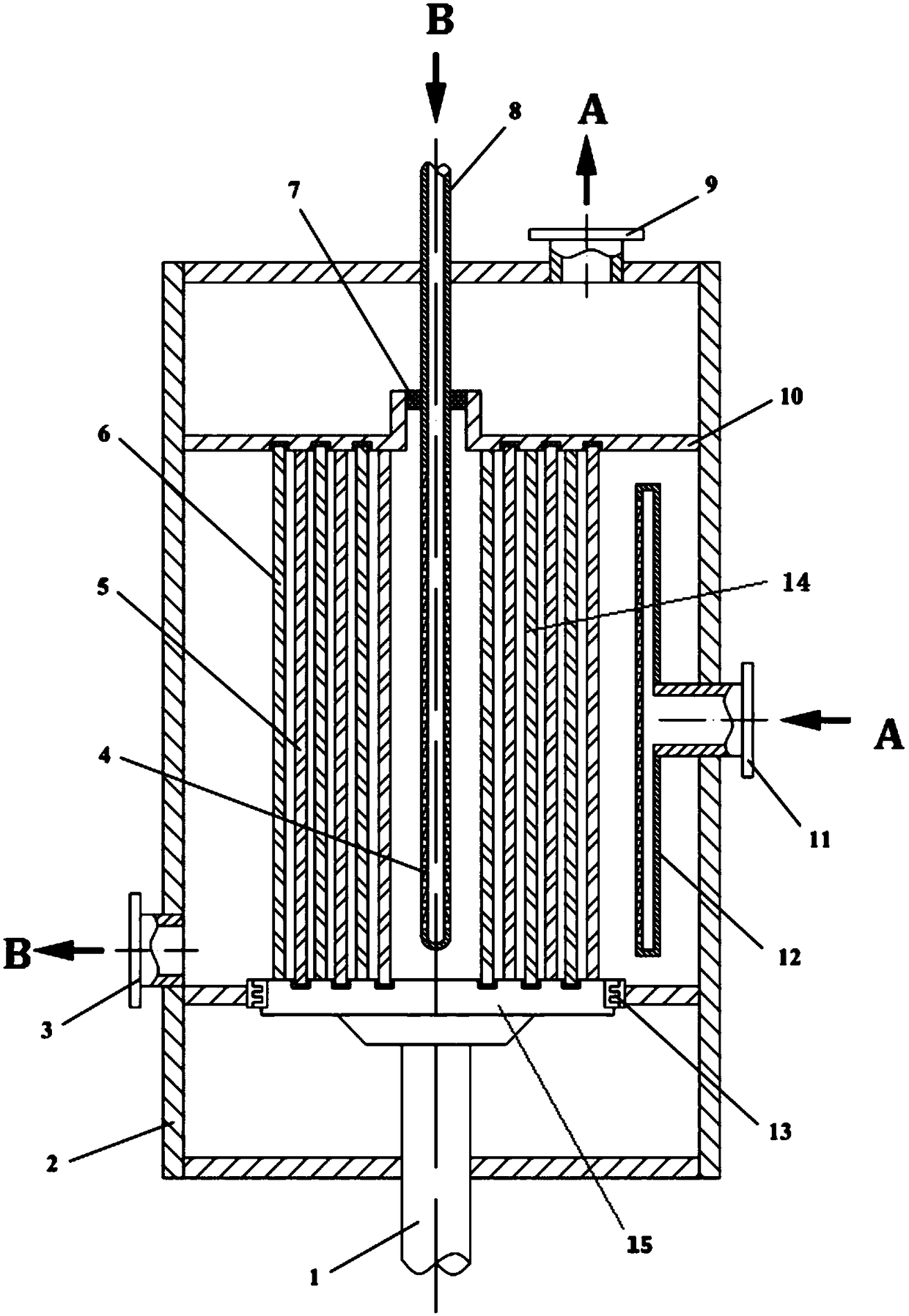

[0053] Embodiment 3: using the device of the present invention, the device has a static ring gap cylinder, each of which is 3 static ring gap cylinders and dynamic ring gap cylinders, arranged concentrically and alternately, as figure 2 shown. The flow rate of aviation kerosene RP-3 is 1ml / s, the thickness of lipophilic dispersed packing is 100mm, the inlet oil temperature is room temperature, and the oxygen content is 70ppm; the rotating shaft speed is 500r / min, the system gauge pressure is 0.1MPa, and the nitrogen ventilation rate is 100ml / s, ventilation time is 5min. Results: The oxygen content of aviation kerosene RP-3 at the drain was 8ppb.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com