Preparation method of environment-friendly smokeless (acidic) molten steel refining agent

A refining agent and acidic technology, which is applied in the field of environment-friendly smokeless (acidic) molten steel refining agent preparation, can solve the problems of unsatisfactory production, quality, cost, environmental protection, lack of compound function for removing molten steel, high content of impurity elements, etc., and achieve convenient Mechanical and manual feeding, prevent the accident of stop pouring, and the effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

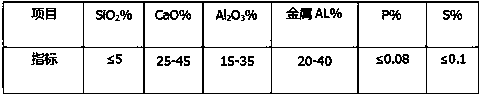

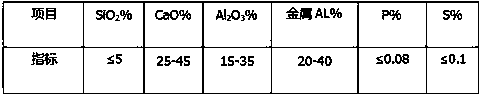

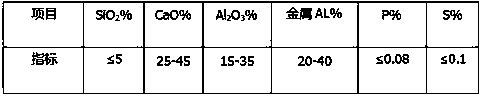

[0021] The specific implementation manners of the present invention will be described in detail below. A method for preparing an environmentally friendly smokeless (acidic) molten steel refining agent, the refining agent is composed of component A and component B, the component A is a silicon-based deoxidizer, and the dosage is 40-50% by mass, the The composition and dosage of component B are silicate, carbonate or passivated lime single or any combination, the dosage is 50-60% by mass, and the refining agent is alkalinity R≥2.0 (CaO / SiO2) , N≤0.06%, the silicates, carbonates or passivated stones are all made of mechanical pressure balls, and the indicators of each part are:

[0022]

[0023] The mechanical briquetting process is dry mechanical mixing and pressing, and the shape is oblate, and the pressing steps are as follows:

[0024] Step (1): Material preparation, according to the requirements of the production formula, the required various inspection qualified raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com