High-heat-conductivity silicon nitride ceramic and preparation method thereof

A technology of silicon nitride ceramics and high thermal conductivity, which is applied in the field of ceramic material preparation, can solve the problems affecting the improvement of mechanical properties and thermal conductivity, the low thermal conductivity of polycrystalline silicon nitride ceramics, and the difficulty of industrialization. Achieve the effects of avoiding phonon scattering, safe use, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing silicon nitride ceramics with high thermal conductivity, which includes the following steps:

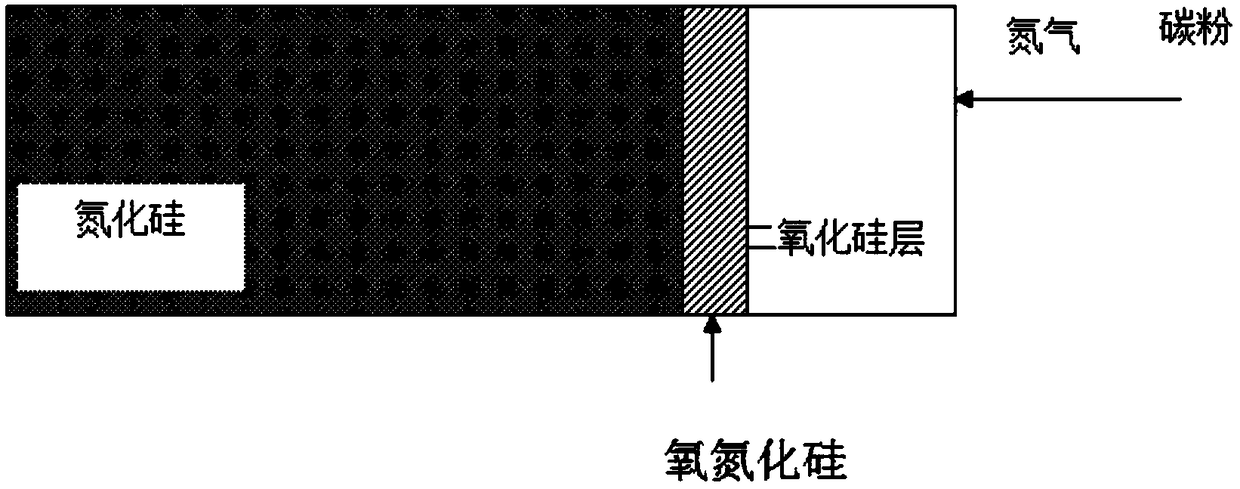

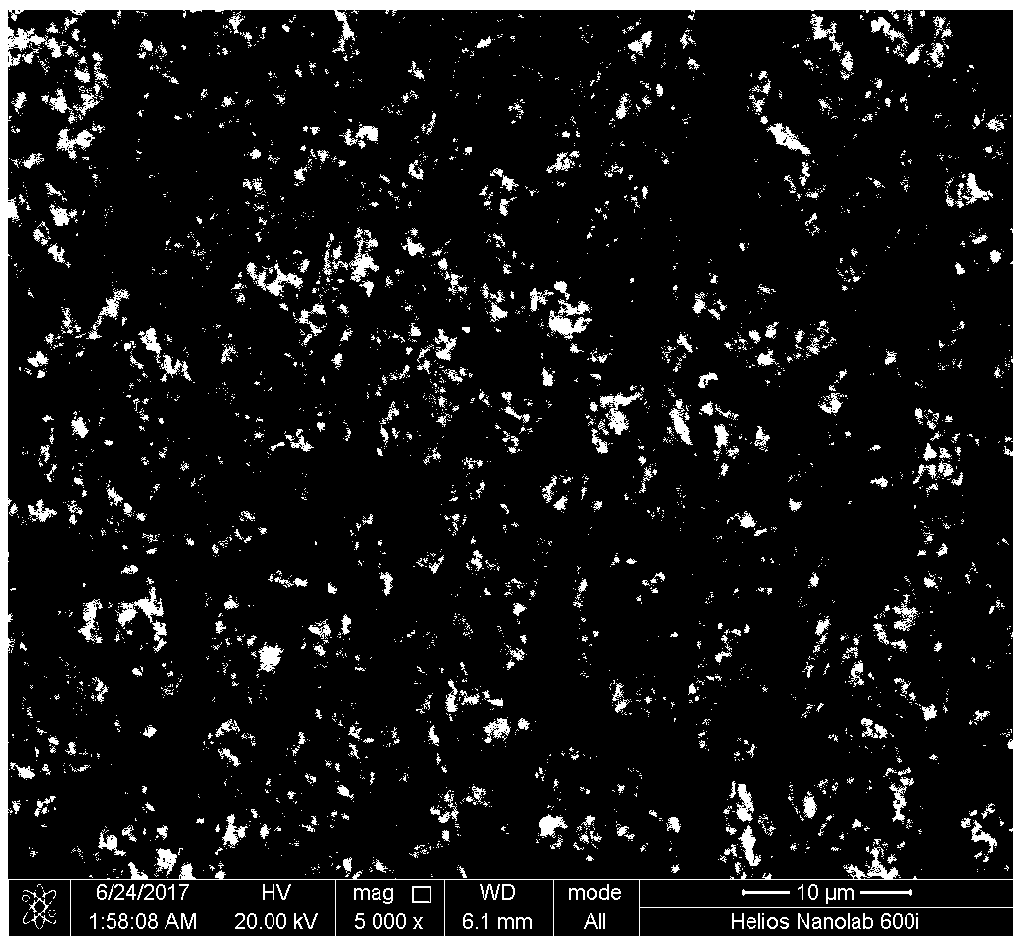

[0028] In the first step, the silicon nitride powder and the carbon powder are respectively placed in a boron nitride crucible, placed in an alumina tube furnace, and heated at a rate of 5-10°C / min in a nitrogen reaction atmosphere. Treat at 1200°C-1400°C for 4-8h, after the reaction is completed, the furnace temperature is naturally cooled, and the treated powder is ground and sieved;

[0029] In the second step, the silicon nitride powder and the sintering aid described in the first step are mixed under the action of the mixing medium, and after the mixing is completed, they are dried and sieved to obtain a powder; wherein the sintering aid is a binary composite A sintering aid, and the binary composite sintering aid includes a rare earth oxide and an alkaline earth metal compound, and the rare earth oxide is Y 2 o 3 , Yb 2 ...

Embodiment 2

[0039]The difference between this example and Example 1 is that the nitrogen reaction atmosphere in the first step is replaced by an ammonia reaction atmosphere, and the others are the same as in Example 1. Ammonia treatment can also deoxidize the silicon nitride powder, and ammonia reacts with the silicon dioxide layer on the surface of the silicon nitride powder. Thermal conductivity of sintered silicon nitride.

Embodiment 3

[0041] This embodiment provides a method for preparing silicon nitride ceramics with high thermal conductivity, which includes the following steps:

[0042] In the first step, the silicon nitride powder and the carbon powder are put into boron nitride crucibles respectively, placed in an alumina tube furnace, and heated at 1200°C in a nitrogen reaction atmosphere at a heating rate of 5°C / min. Process at ℃ for 4 hours, after the reaction is completed, the furnace temperature is naturally cooled, and the treated powder is ground and sieved;

[0043] In the second step, the silicon nitride powder and the sintering aid described in the first step are mixed under the action of the mixing medium, and after the mixing is completed, they are dried and sieved to obtain a powder; wherein the sintering aid is a binary composite A sintering aid, and the binary composite sintering aid includes a rare earth oxide and an alkaline earth metal compound, and the rare earth oxide is Y 2 o 3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com