Method for preparation of load type nano metallic catalyst

A catalyst, supported technology, used in chemical instruments and methods, chemical methods for reacting liquids, chemical/physical processes, etc., can solve the problem of uneven distribution of active components, low metal dispersion, and large metal loading. and other problems, to achieve the effect of low cost, high metal dispersion and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

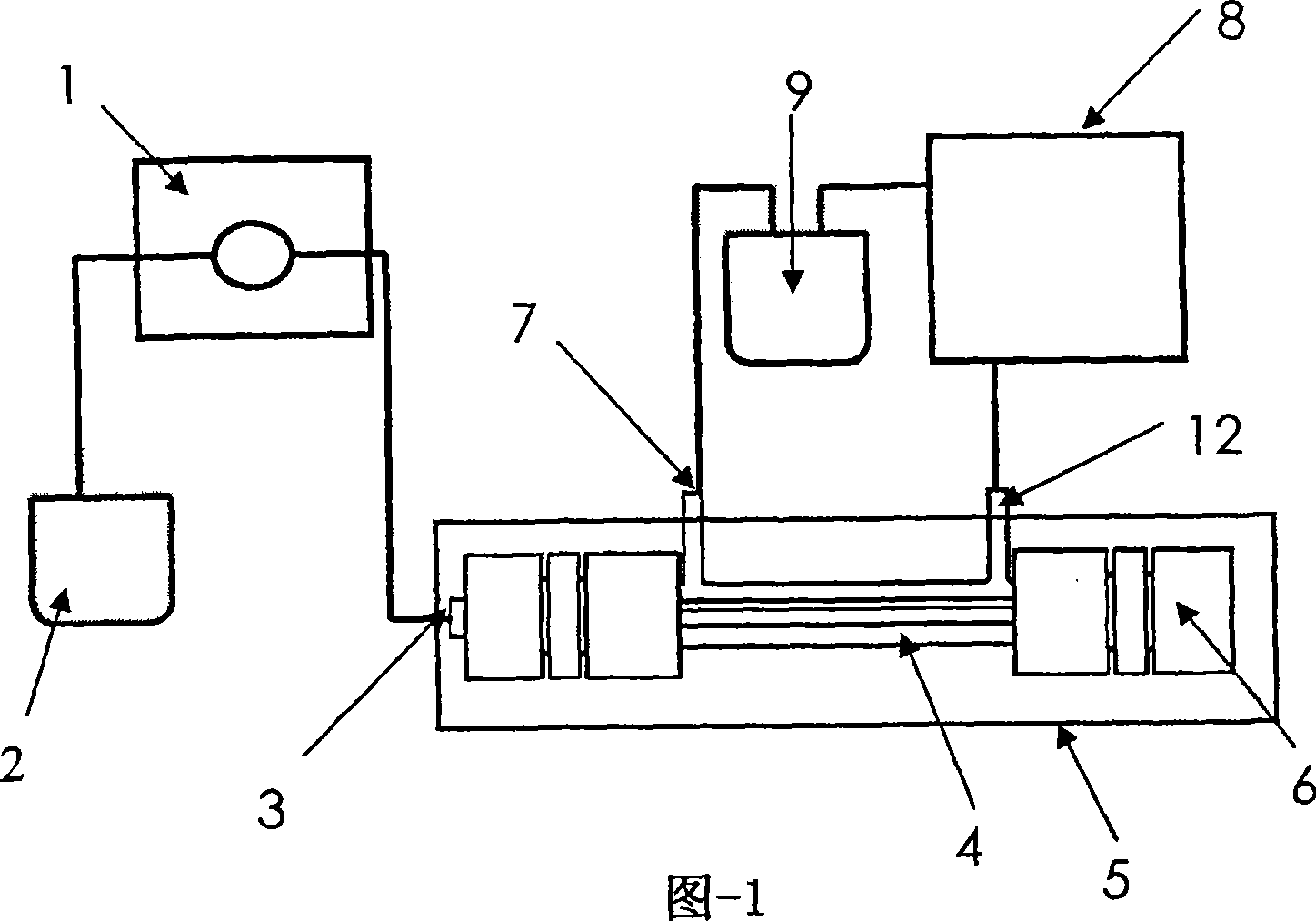

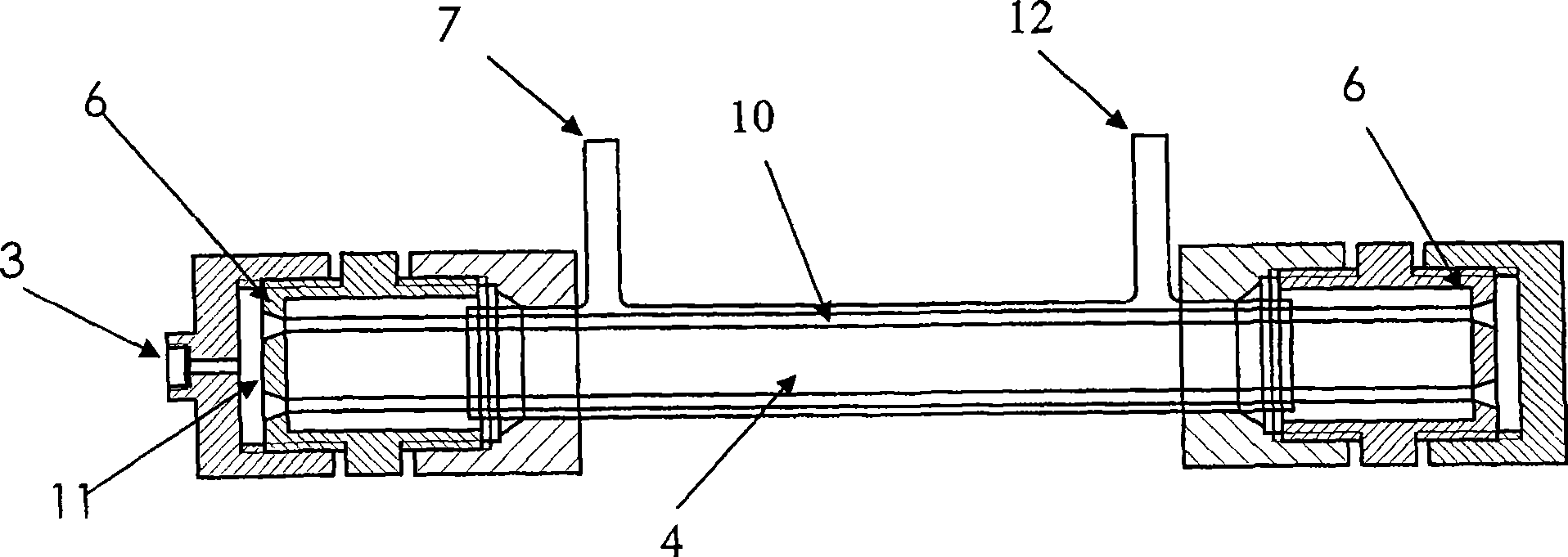

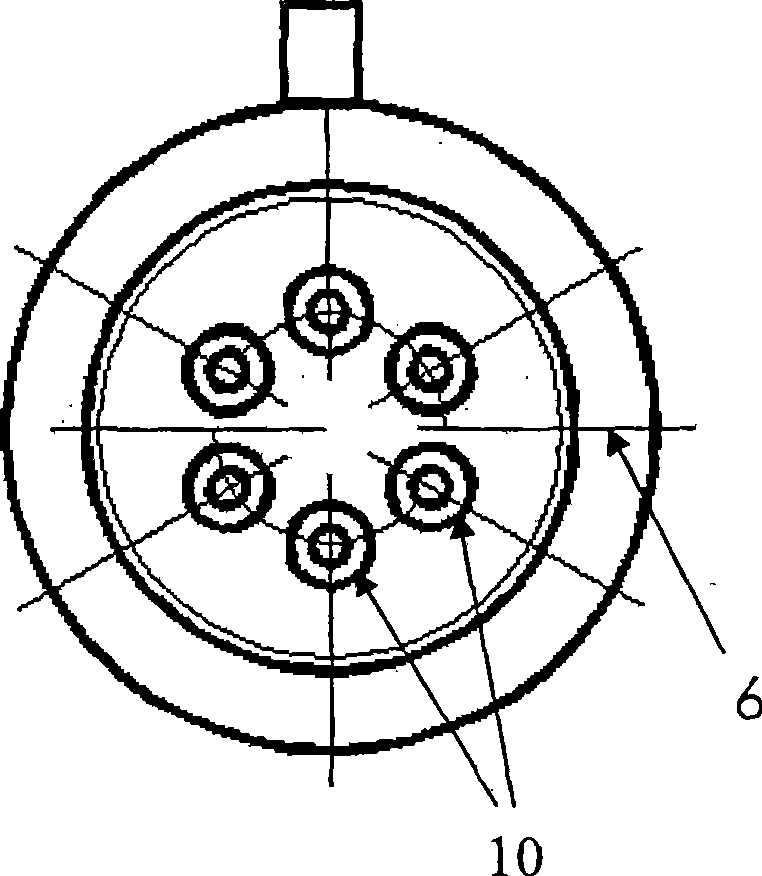

[0032] Weighed sodium borohydride NaBH 4 Dissolve in 200ml deionized water, then add 10g of γ-Al 2 o 3 , transferred to the product storage tank 9 after fully stirring to form a slurry; the weighed chloroplatinic acid H 2 PtCl 6 Dissolve in 50ml deionized water, and transfer the chloroplatinic acid solution to the metal salt solution storage tank 2, start the infusion pump 8, and make NaBH 4 and γ-Al 2 o 3 The mixed slurry circulates between the product storage tank 9 and the tubular reactor 4, the flow rate is 800ml / min, the ultrasonic generator 5 is started, the transmission frequency is set to 60 kHz, the temperature of the water bath is 60°C, and the metering pump 1 is set at 1.0 The rate of ml / min will be H 2 PtCl 6 The solution is injected into the pipeline of the hollow ceramic tube 10 in the tubular reactor 4, H 2 PtCl 6 The solution diffuses through the micropores of the hollow ceramic membrane tube wall 10 to the 4 and γ-Al 2 o 3 In the mixed slurry, when...

Embodiment 2

[0034] Weighed sodium borohydride (NaBH 4 ) was dissolved in 300ml deionized water, and then 15 grams of γ-Al was added 2 o 3 , transferred to the product storage tank 9 after fully stirring to form a slurry; the weighed rhodium chloride (RhCl 3 ) and chloroauric acid (HAuCl 4 ) was dissolved in 100 ml deionized water and transferred to metal salt solution storage tank 2. Start the infusion pump 8 to make NaBH 4 and γ-Al 2 o 3 The mixed slurry circulates between the product storage tank 9 and the tubular reactor 4, the flow rate is 500ml / min, the ultrasonic generator 5 is started, the frequency of the ultrasonic generator is set to 40 kHz, the water bath temperature is 40 °C, and the metering pump 1 Rhodium chloride (RhCl 3 ) and chloroauric acid (HAuCl 4 ) of the mixed solution is injected into the pipeline of the hollow ceramic membrane tube 10 in the tubular reactor 4, RhCl 3 and HAuCl 4 The mixed solution diffuses through the micropores on the wall of the hollow ...

Embodiment 3

[0036]Weighed sodium borohydride NaBH 4 Dissolve in 200ml deionized water, then add 10g of γ-Al 2 o 3 , transferred to the product storage tank 9 after fully stirring to form a slurry; the weighed palladium nitrate (Pd(NO 3 ) 2 2H 2 0) be dissolved in 50ml deionized water, and palladium nitrate solution is transferred in metal salt solution storage tank 2, start infusion pump 8, make NaBH 4 and γ-Al 2 o 3 The mixed slurry circulates between the product storage tank 9 and the tubular reactor 4, the flow rate is 500ml / min, the ultrasonic generator 5 is started, the transmission frequency is set to 120 kHz, the water bath temperature is 60°C, and the metering pump 1 takes 10ml Palladium nitrate solution is injected into the pipeline of the hollow ceramic tube 10 in the tubular reactor 4 at the speed of / min, and the palladium nitrate solution is diffused to contain NaBH by the micropore of hollow ceramic membrane tube wall 10 4 and γ-Al 2 o 3 In the mixed slurry, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com