Atomic-scale metal manganese-loaded nitrogen-doped mesoporous carbon nano-microsphere and application of atomic-scale metal manganese-loaded nitrogen-doped mesoporous carbon nano-microsphere

A nitrogen-doped mesoporous carbon and nano-microsphere technology is applied in nano-carbon, fuel cell-type half-cell and primary-cell-type half-cell, structural parts, etc. Effects of low central atom coordination number, high CO2 selectivity, and high electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) 6g Pluronic F127, 2g Pluronic P123 and 12g dopamine hydrochloride were added to a mixed solvent consisting of 400mL of water and 400mL of ethanol, and fully stirred to form a completely transparent monomer solution;

[0052] (2) Add 32 mL of 1,3,5-tritoluene (C 9 H 12 , TMB), stir for 1 h at 500 r / min, and then ultrasonicate for 15 min at 200 W ultrasonic power to form a milky white nano-microemulsion system; then add 30 mL of ammonia water with a mass fraction of 25%, and at 25 ° C at 800 r / The reaction was stirred at a stirring rate of min for 5 hours, and then the solid product was collected by centrifugation, washed with water and ethanol, and then freeze-dried at -75 °C for 24 hours to obtain a dopamine polymer;

[0053] (3) Dissolve 24 mg of manganese acetate in 100 mL of water to prepare a manganese salt aqueous solution; add 50 mg of dopamine polymer to the manganese salt aqueous solution, stir and react in an oil bath at 50 °C for 10 h, and then freeze-dr...

Embodiment 2

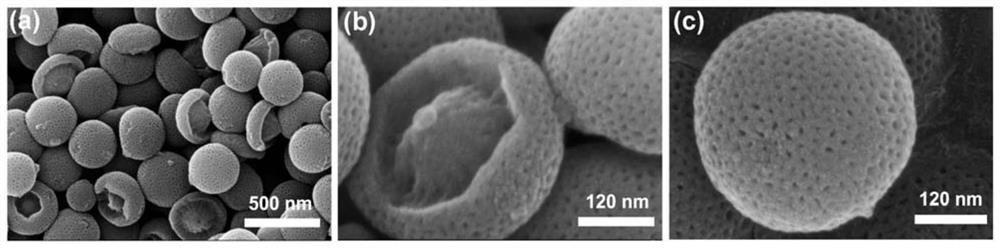

[0080] On the basis of Example 1, except that 1,3,5-trimethylbenzene (C 9 H 12 , TMB) was modified from 32mL to 16mL, and other steps and conditions were the same as in Example 1. Correspondingly, nitrogen-doped golf ball-shaped mesoporous carbon nanospheres supported by atomic manganese metal were obtained.

[0081] Figure 16 This is the FE-SEM image of the prepared golf ball-shaped mesoporous carbon nano-microspheres. It can be seen from the figure that the prepared mesoporous carbon nano-microspheres have a homogeneous golf ball structure with a diameter of about 150 nm. This is due to the swelling effect, as the TMB content in the ethanol / water solvent decreases, the pore size in the nanoemulsion gradually decreases, thereby forming a uniform porous structure with nanopores in the self-polymerization of dopamine; meanwhile, due to the TMB content Less, the role of TMB is only as a pore-enlarging agent, and cannot become the growth bed of nanocarbon, which leads to the d...

Embodiment 3

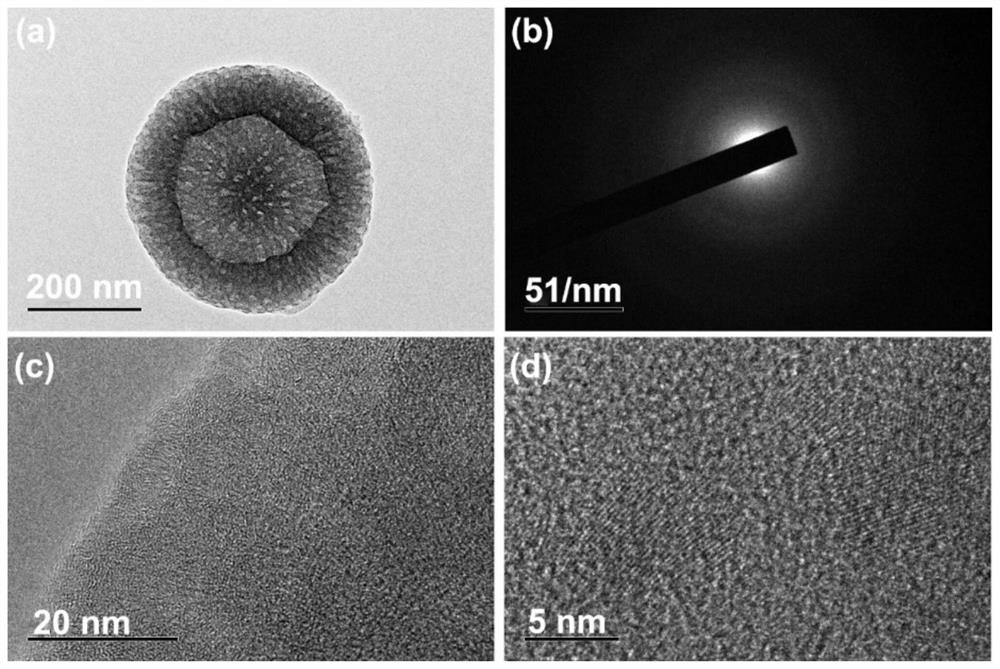

[0086] On the basis of Example 1, except that 1,3,5-trimethylbenzene (C 9 H 12 , TMB) was added from 32mL to 4mL, and other steps and conditions were the same as in Example 1. Correspondingly, nitrogen-doped spherical mesoporous carbon nanospheres supported by atomic manganese metal were obtained.

[0087] Figure 21 is the FE-SEM image of the prepared spherical mesoporous carbon nano-microspheres. It can be seen from the figure that the spherical carbon nanoparticles exhibit a smooth surface shape as the content of TMB in the monomer solution is further reduced. The particle diameter is ~200 nm.

[0088] Figure 22 For the TEM image of the prepared spherical mesoporous carbon nanospheres, it can be seen that there are a certain number of channels inside the particles. combine Figure 23 and Figure 24 The adsorption isotherm and pore size distribution curve of spherical mesoporous carbon nanospheres, the isotherm is at P / P 0 A sharp increase at 0 In the 2 / g, the corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com