Nickel silicate-derived catalyst for producing xylitol by hydrogenation of xylose as well as preparation and application of nickel silicate-derived catalyst

A catalyst, nickel silicate technology, applied in catalyst activation/preparation, molecular sieve catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of low xylitol selectivity, complex catalyst composition, environmental pollution, etc. problem, to achieve the effect of high xylitol selectivity, suitable for large-scale industrial application, and high metal loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation and Application of 50Ni / SBA-15-EA Catalyst

[0046] 24.8g Ni(NO 3 ) 2 ·6H 2 O was dissolved in deionized water, and high-purity ammonia gas was pulsed into the above solution. After the pH of the system no longer increased, the ammonia gas was stopped, and the obtained solution system was stirred for 20 minutes. Weigh 5g of SBA-15 powder into the solution and stir for 4h at room temperature. The uniformly stirred mixture system was transferred to a water bath at 80°C, and the ammonia gas in the mixture was continuously stirred to remove it. After the pH of the system was reduced to nearly neutral, the mixture was removed from the water bath to cool down. After the system was cooled to room temperature, filter cake was obtained by filtration. After washing the filter cake with deionized water for 5 times, the filter cake was dried at 120°C for 12h, then roasted at 650°C for 4h, and reduced in a hydrogen atmosphere at 500°C for 2h. The catalyst is designa...

Embodiment 2

[0049] 30Ni / SiO 2 - Preparation and application of EA catalyst

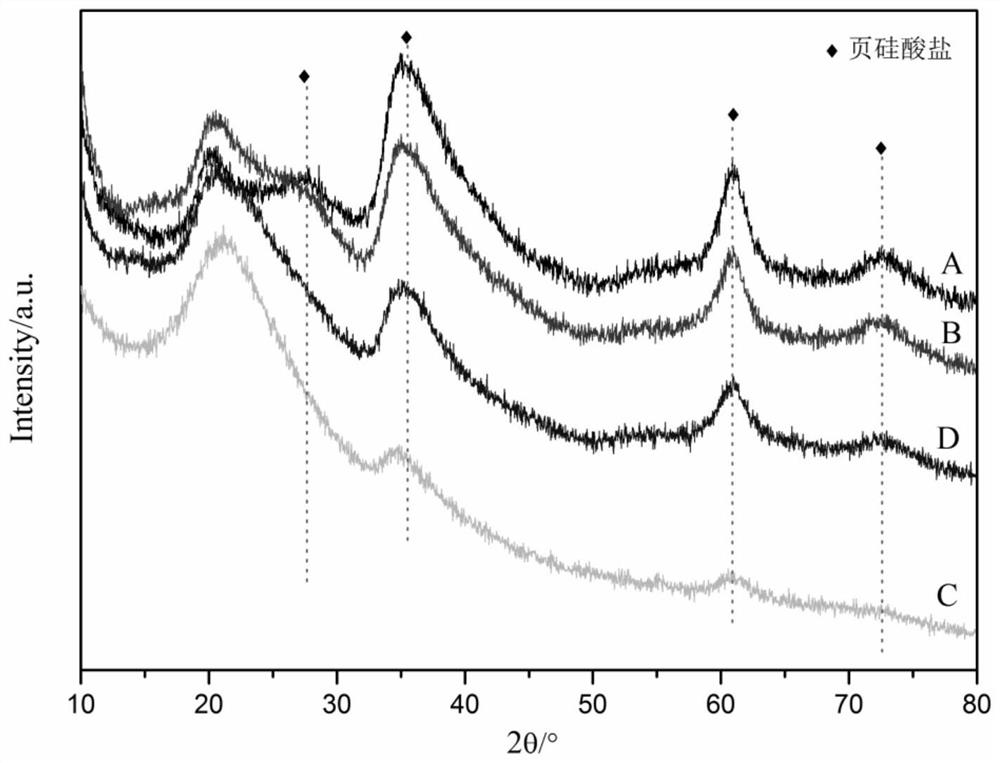

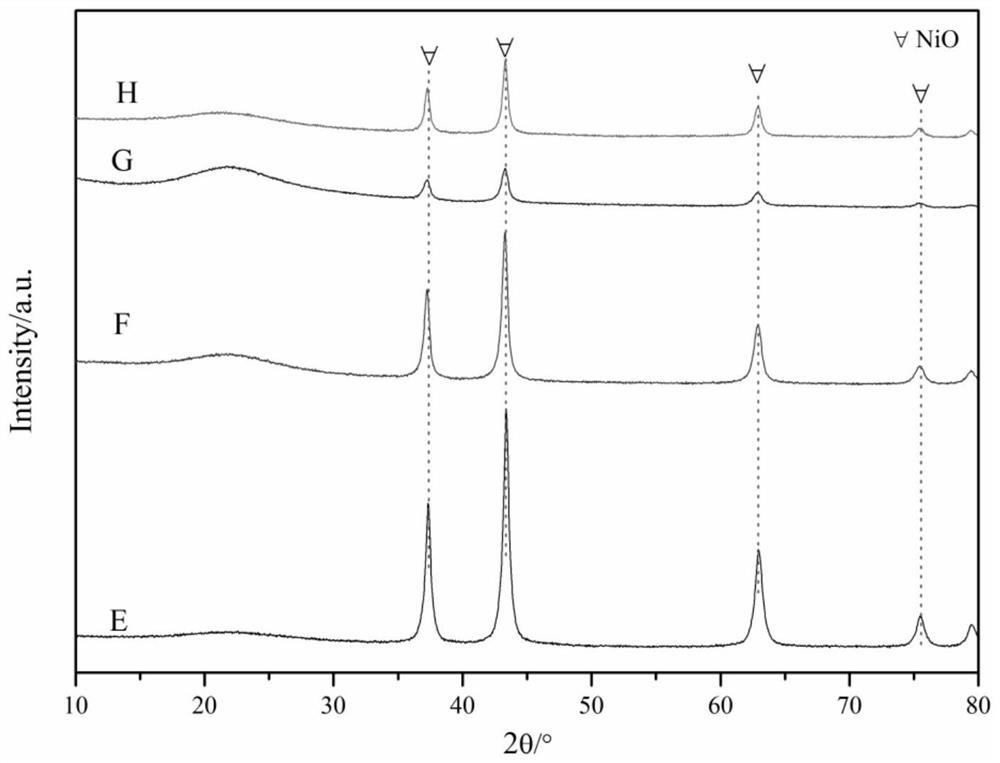

[0050] 10.6g Ni(NO 3 ) 2 ·6H 2 O was dissolved in deionized water to obtain solution A. Prepare 0.5M Na 2 CO 3 solution, solution B. Weigh 5g of SiO produced by Shandong Ocean Chemical 2 The powder was added to the solution to obtain Suspension C. Heat C to 50°C, and under constant temperature stirring, add A and B into the system simultaneously and at a constant speed to keep the pH of the system constant. After the dropwise addition was completed, the stirring aging treatment was continued for 2 h at this temperature. The system was cooled to room temperature, and filtered to obtain a filter cake. After washing the filter cake with deionized water for 5 times, the filter cake was dried at 120°C for 12h, then roasted at 700°C for 4h, and reduced in a hydrogen atmosphere at 600°C for 2h. The catalyst is designated as B. Sample B was characterized by XRD ( figure 1 ), proving that the nickel component...

Embodiment 3

[0053] Preparation and Application of 5Ni / MCM-41-EA Catalyst

[0054] 1.3g Ni(NO 3 ) 2 ·6H 2 O was dissolved in deionized water, 15 g of urea was added, and the obtained solution system was stirred for 20 min. Weigh 5g of MCM-41 powder into the solution and stir at room temperature for 2h. The reaction system was heated to 50°C, and the urea was decomposed slowly under stirring, and the temperature of the mixture was lowered after the pH of the system was lowered to near neutral. After the system was cooled to room temperature, filter cake was obtained by filtration. After washing the filter cake with deionized water for 5 times, the filter cake was dried at 120°C for 12h, then roasted at 450°C for 4h, and reduced in a hydrogen atmosphere at 400°C for 2h. The catalyst is designated as C. Sample C was characterized by XRD ( figure 1 ), proving that the nickel component in the sample exists in the form of nickel phyllosilicate (nickel phyllosilicate, layered nickel silica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com