Magnetoresistance effect device and method of production of the same

a technology of magnetic effect and magnetic field, which is applied in the field of magnetic field, can solve the problems of less suitable mass production process, and achieve the effects of excellent properties, extremely high mr ratio, and excellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, a preferred embodiment of the present invention will be explained with reference to the attached drawings.

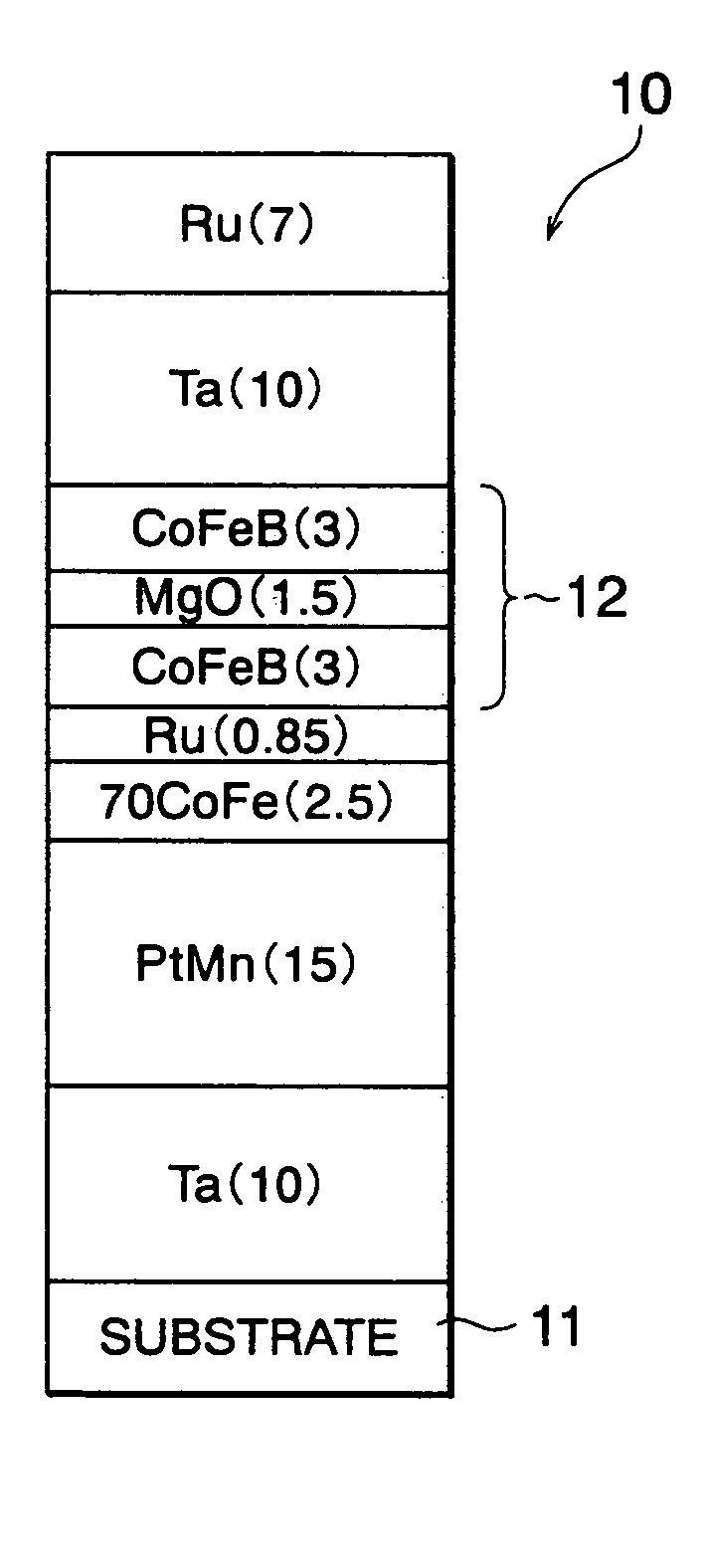

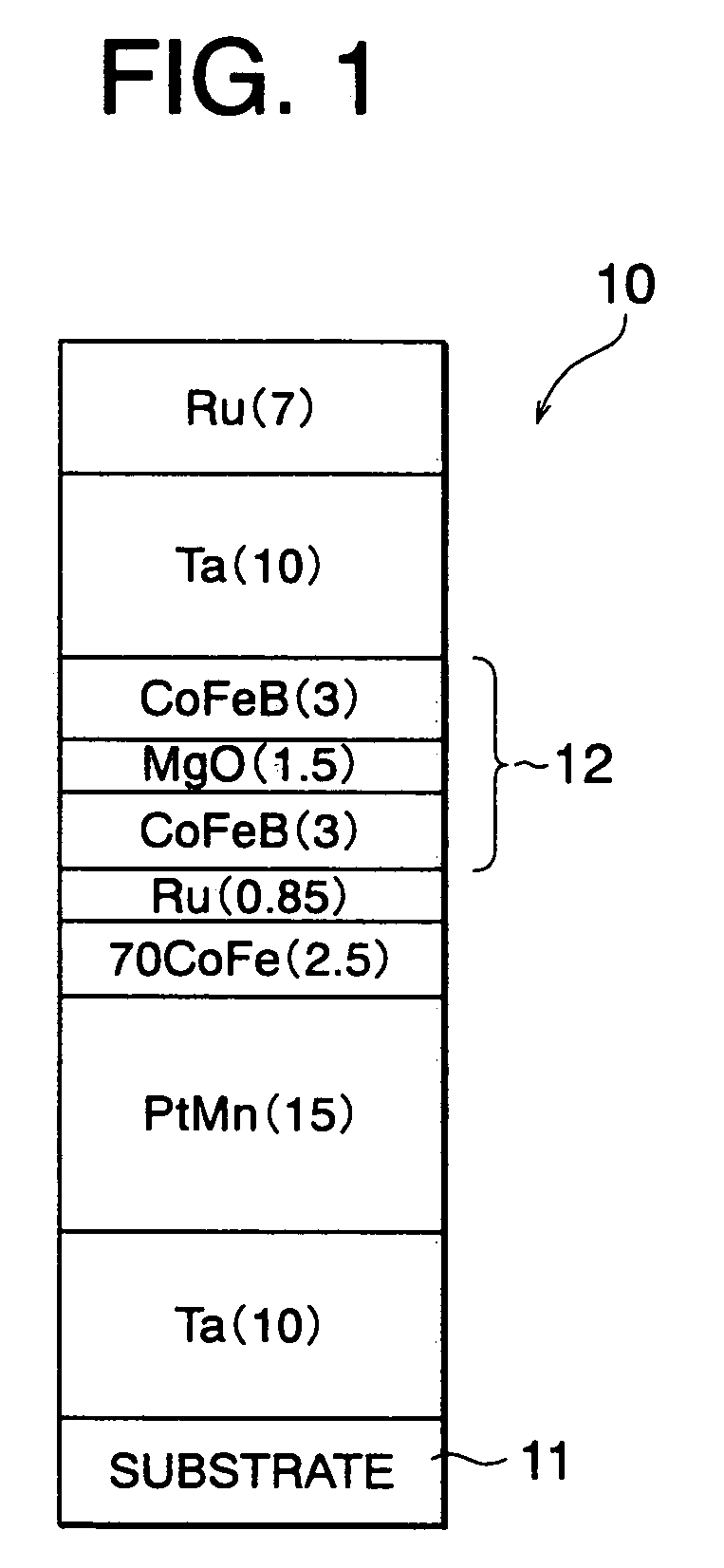

[0030]FIG. 1 shows an example of the multilayer structure of a magnetoresistance effect device according to the present invention, in particular shows the multilayer structure of a TMR device. According to this TMR device 10, a substrate 11 is formed with a multilayer film comprised of for example nine layers forming the TMR device 10. In this nine-layer multilayer film, magnetic films etc. are stacked from the bottommost first layer to the topmost ninth layer with “Ta”, “PtMn”, “70CoFe”, “Ru”, “CoFeB”, “MgO”, “CoFeB”, “Ta”, and “Ru” in that order. The first layer (Ta: tantalum) is an undercoat layer, while the second layer (PtMn) is an anti-ferromagnetic layer. The layers from the third layer to the fifth layer (70 CoFe, Ru, CoFeB) form fixed magnetization layers. The substantive fixed magnetization layer is the fifth layer ferromagnetic layer comprised of “CoFeB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| fiber-texture structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com