Modular firearm stock system

a firearm and stock system technology, applied in the field of modular firearms, can solve the problems of impracticality of carrying multiple different firearms, adding undue weight and bulk to soldiers' packs and gear, etc., and achieve the effect of ease of actuation or engagemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

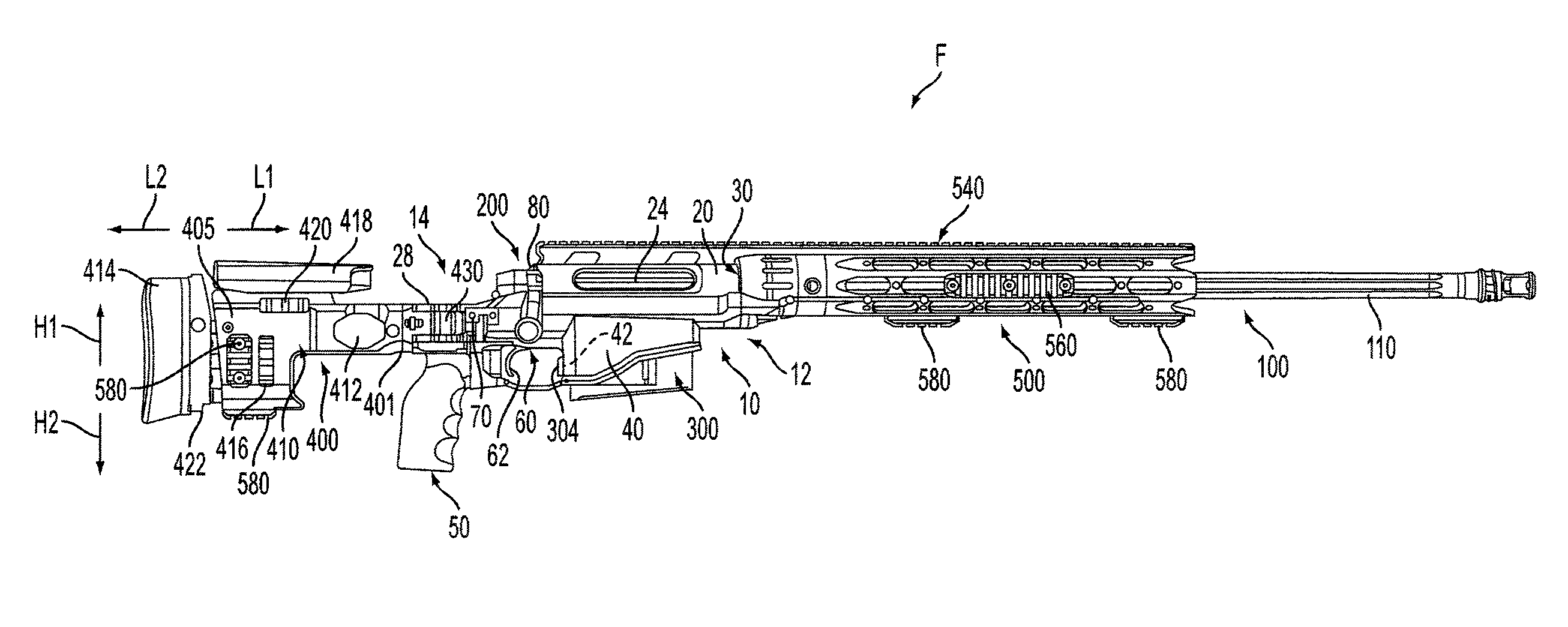

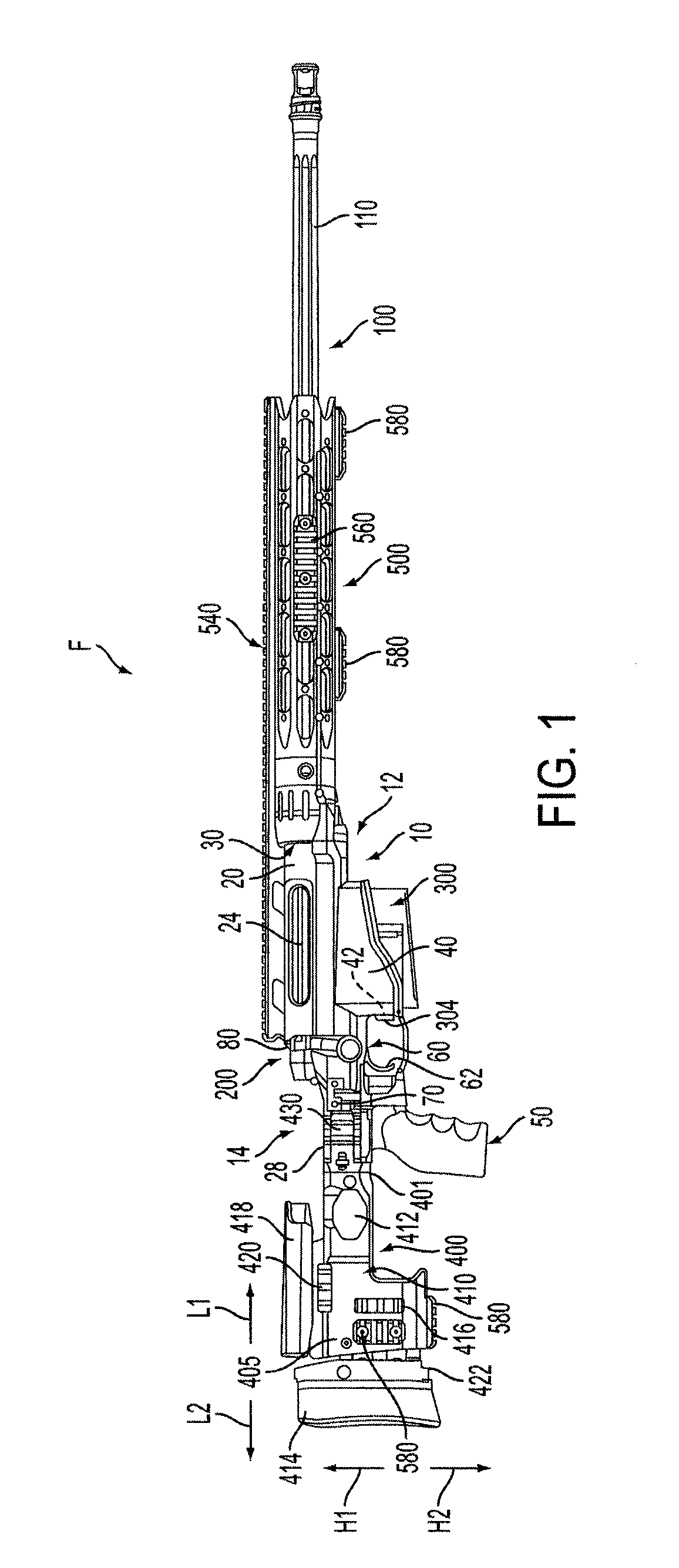

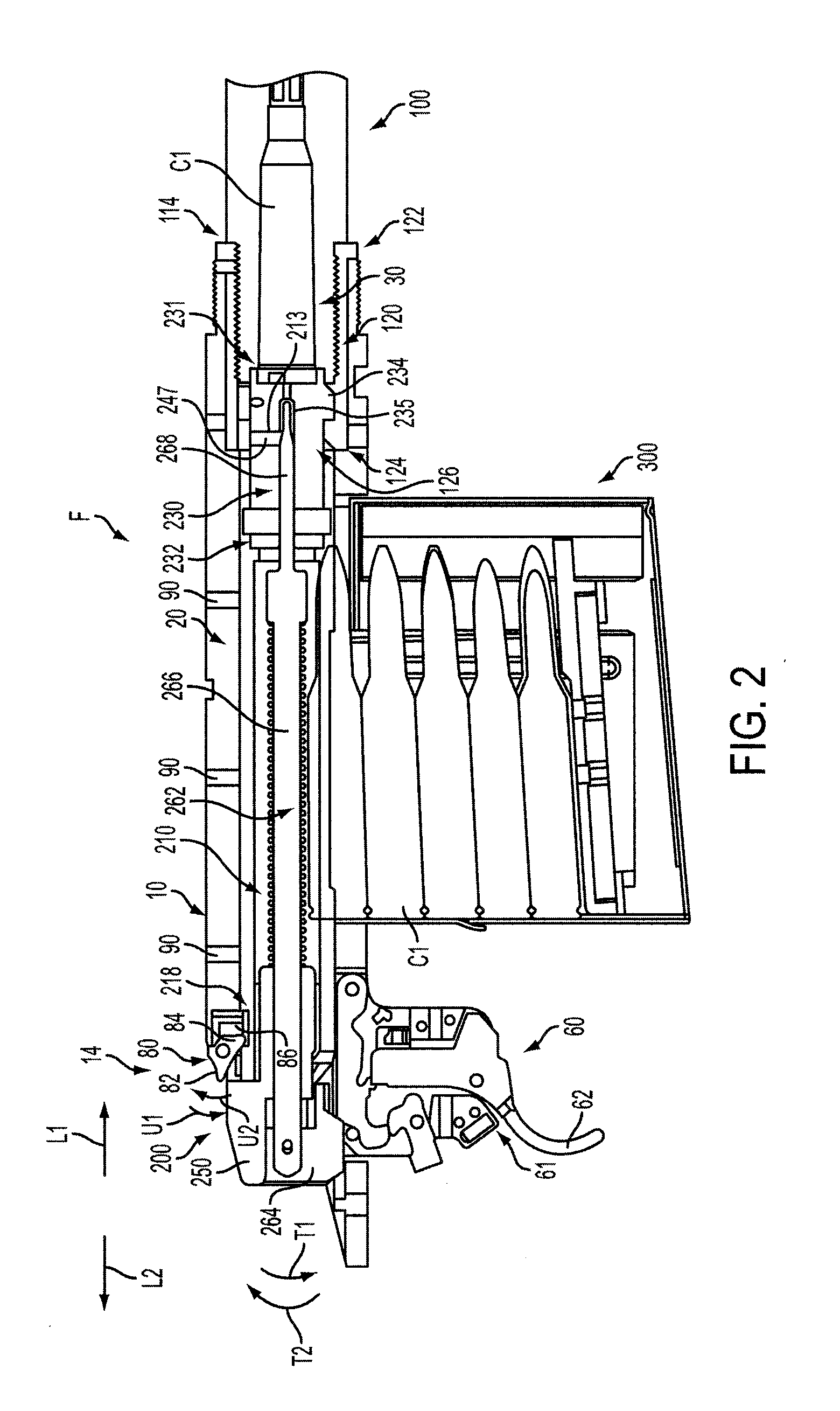

[0025]FIGS. 1-16 show various features and components of a modular firearm F according to at least one example embodiment of the invention. In particular, the modular firearm F is shown as a bolt-action rifle, and more specifically, a bolt-action sniper rifle. However, it will be understood by those skilled in the art that the various aspects of the invention as described herein are suitable for other types of firearms, including various types of semi-automatic and fully automatic firearms such as handguns, rifles, shotguns, and other long-barreled firearms.

[0026]As shown in FIG. 1, the modular firearm F generally includes a frame or chassis 10 including a receiver 20, an interchangeable barrel assembly 100 mounted to the receiver 20 at a front end 12 of the chassis 10 and defining a chamber 30 at a position where the barrel assembly 100 connects to the receiver 20, a magazine well 40 defined in the chassis 10 and in communication with the chamber 30, and a foldable butt stock assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com