Automatic high rack warehouse goods space allocation method

A storage space allocation, high-bay warehouse technology, applied in conveyors, storage devices, transportation and packaging, etc., can solve the problems of low space utilization, outbound blockage, low operation efficiency of automatic high-bay warehouses, etc., to reduce costs, facilitate The effect of management, improving work efficiency and space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

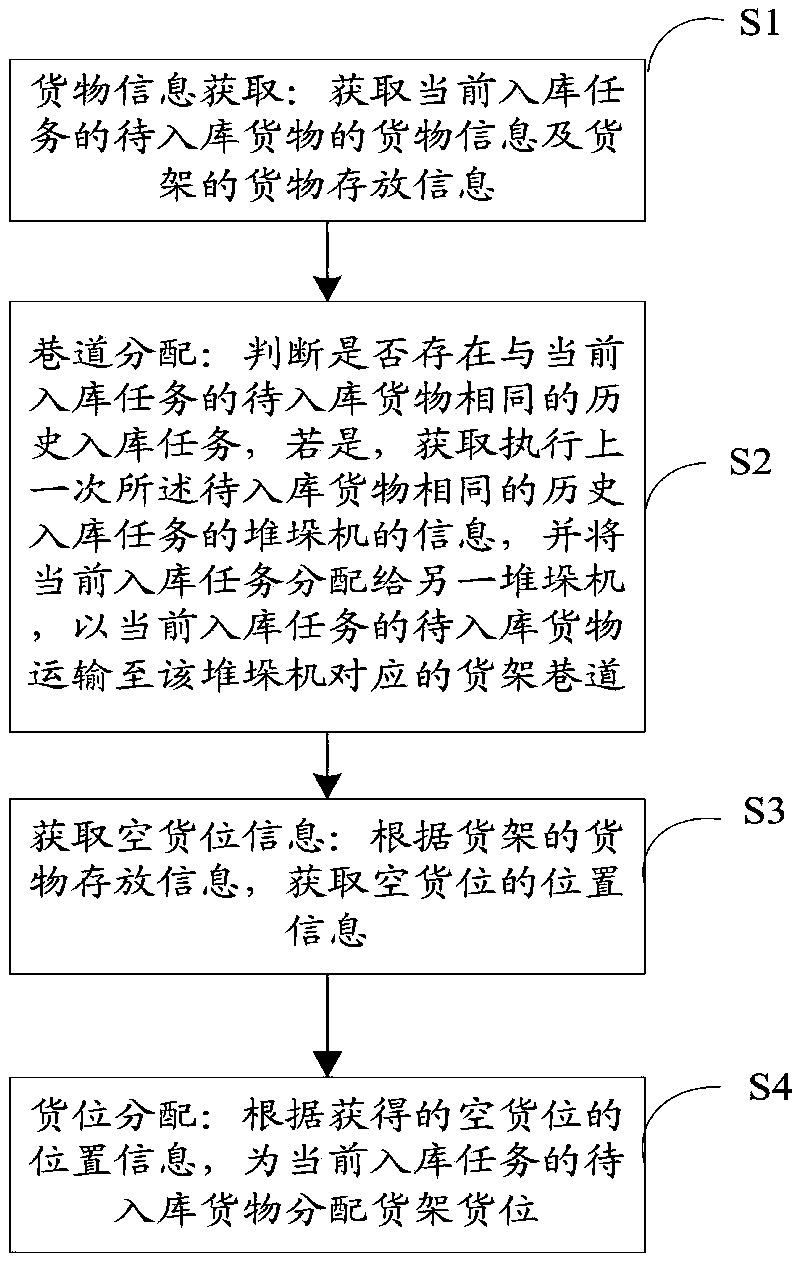

Method used

Image

Examples

no. 1 example

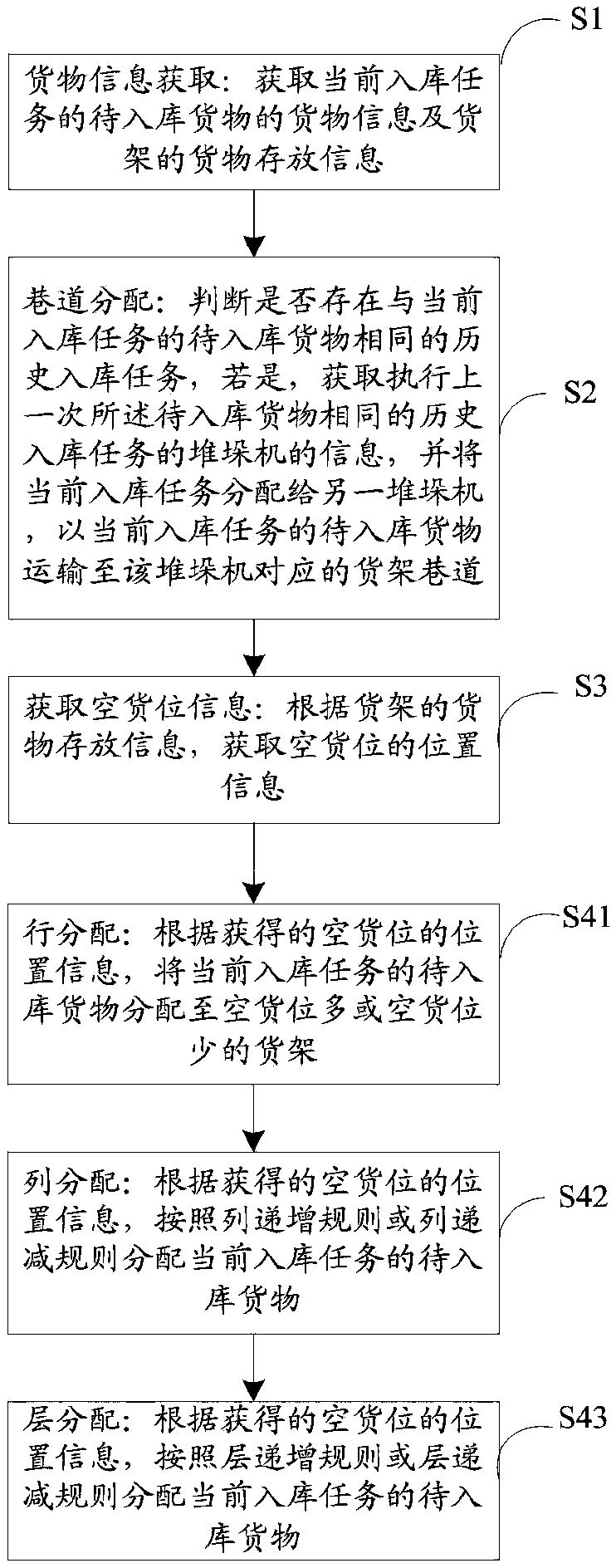

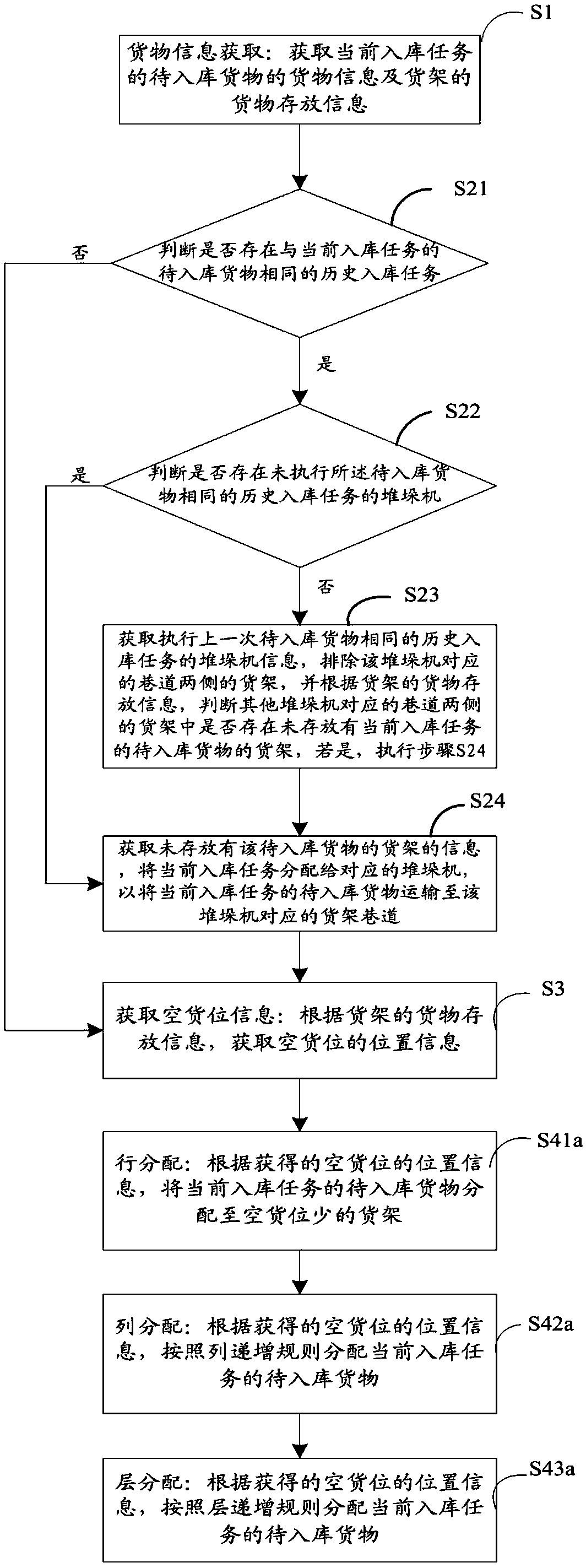

[0042] refer to image 3 , image 3 The first embodiment of the automatic high-bay warehouse location allocation method of the present invention is shown. In this embodiment, the step S4 is specifically:

[0043] Step S41a, row allocation: according to the obtained location information of empty storage spaces, allocate the goods to be stored in the current storage task to the shelves with less empty storage spaces.

[0044] Step S42a, column allocation: according to the obtained position information of the empty storage space, allocate the goods to be stored in the current storage task according to the column increment rule.

[0045] Step S43a, layer allocation: according to the obtained location information of the empty storage space, allocate the goods to be put into storage for the current load-in task according to the layer increment rule.

[0046] Specifically, the step S2 specifically includes the following steps:

[0047] Step S21, judging whether there is a historical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com