Multi-load AGV task assignment forming method for tobacco factory material transport

A task allocation and task technology, applied in logistics, instruments, data processing applications, etc., can solve the problem that global search algorithms are difficult to find task allocation, task points contain complex information, and affect the effectiveness of scheduling results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

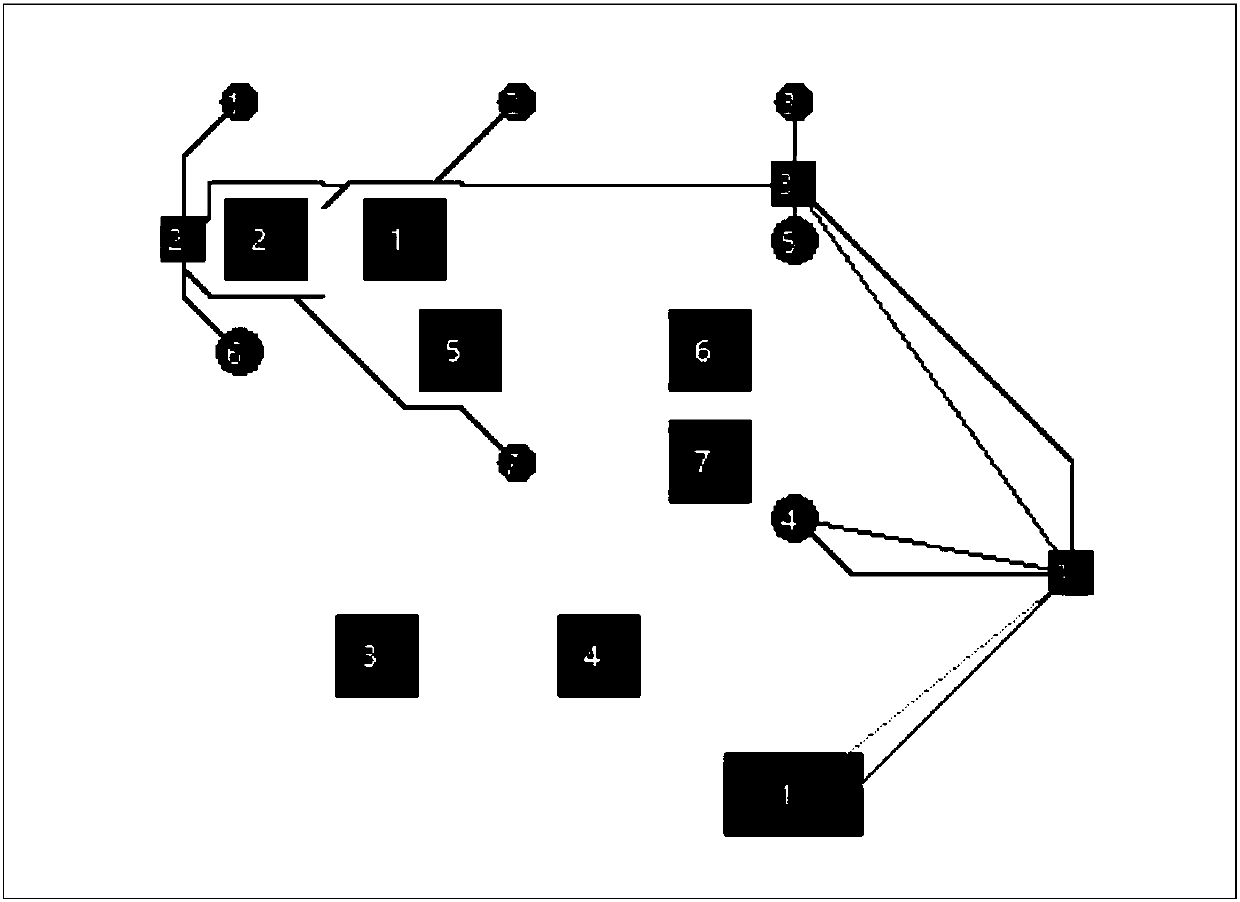

[0084] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

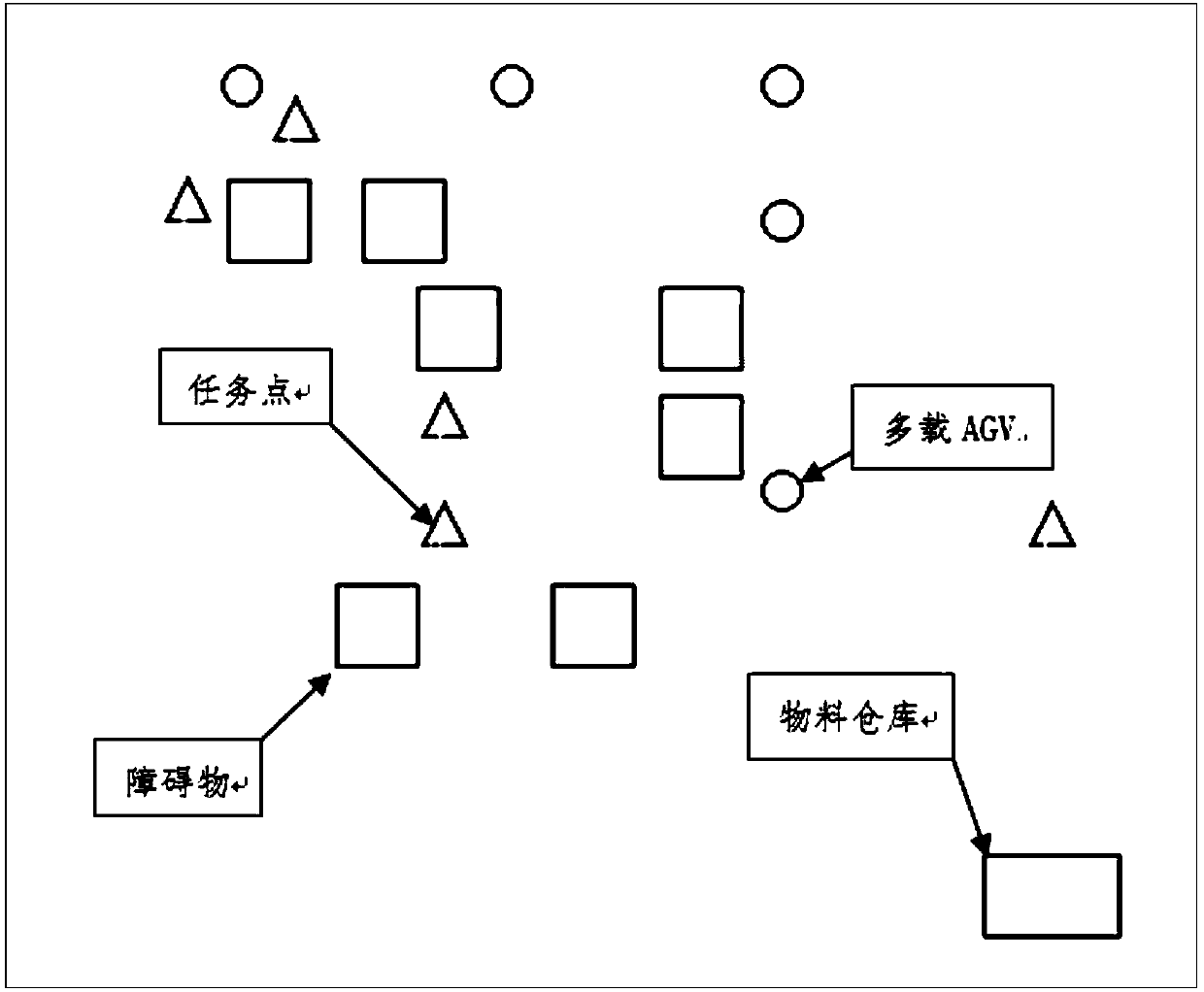

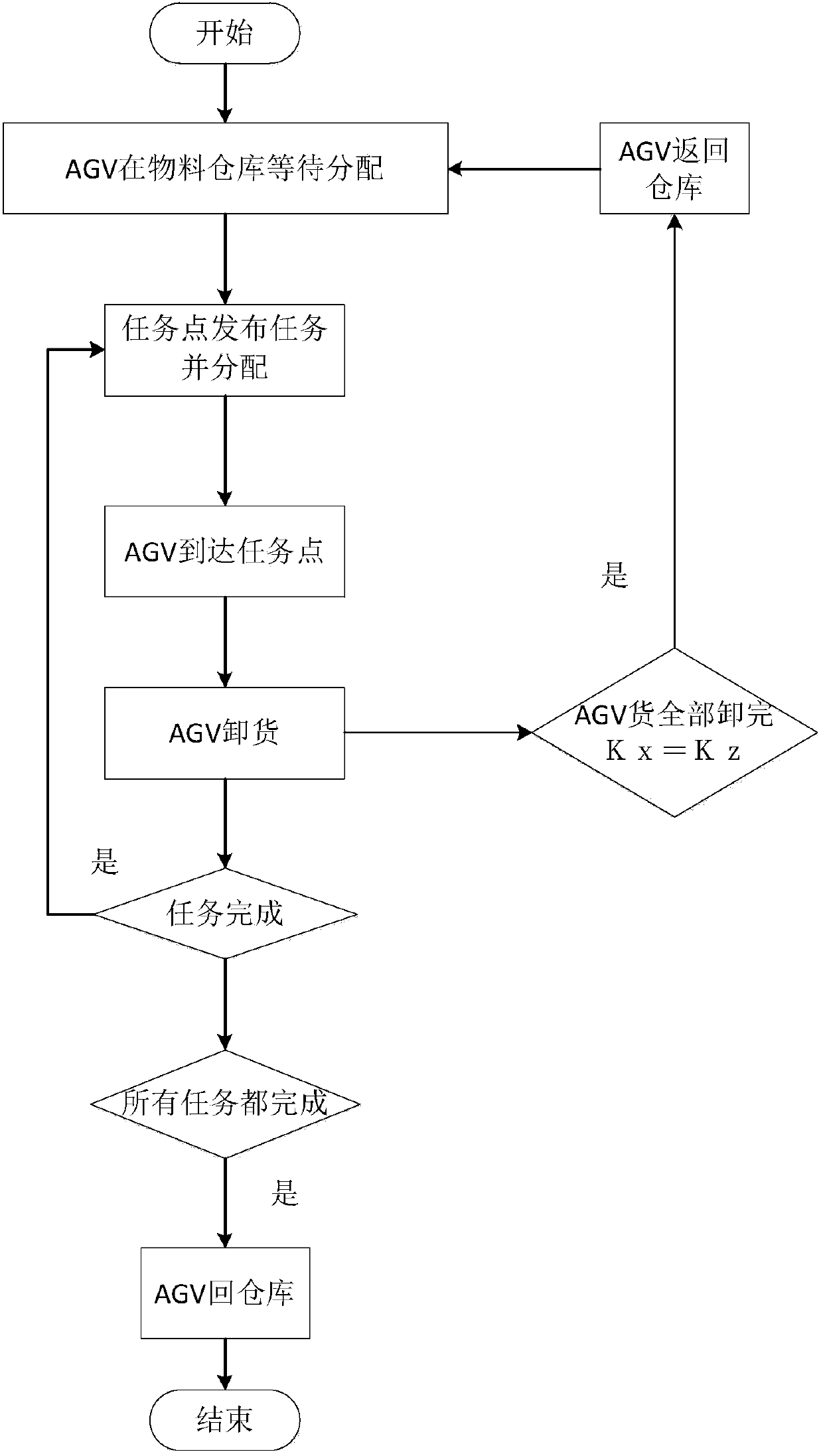

[0085] The present invention provides an auction algorithm for multi-load AGV task assignment for tobacco factory material transportation, and combines A-star algorithm path optimization to solve the problem of multiple tasks with different attributes in the environment through multi-load AGV.

[0086] The invention uses an auction algorithm to improve the efficiency of task allocation; the task completion time is included in the task completion income, and the purpose of optimizing the task completion income is to meet the real-time requirements; through multiple task assignments, the AGV resources can be used to the greatest extent and speed up Task execution speed.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com