Rotating disk transition type bidirectional loading and unloading machine

A technology of loading and unloading machines and turntables, which is applied to conveyor objects, transportation and packaging, supporting frames, etc., can solve the problems of not meeting the requirements of economical and fast loading and unloading, convenient and safe, unavoidable manual auxiliary loading and unloading and handling, and inapplicable to fragile items. , to achieve the effect of convenient and quick movement and transition, reduce the cost of loading and unloading, and avoid falling and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

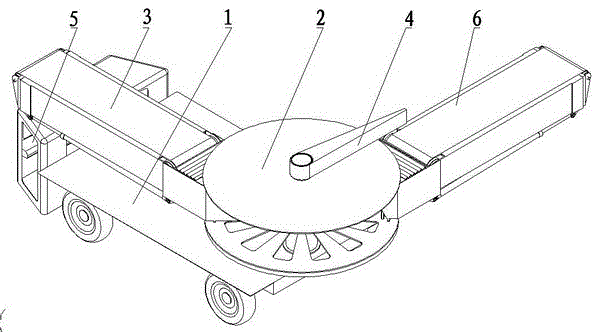

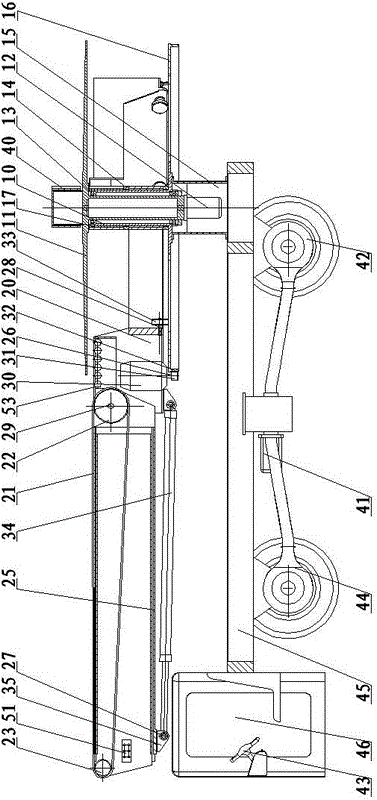

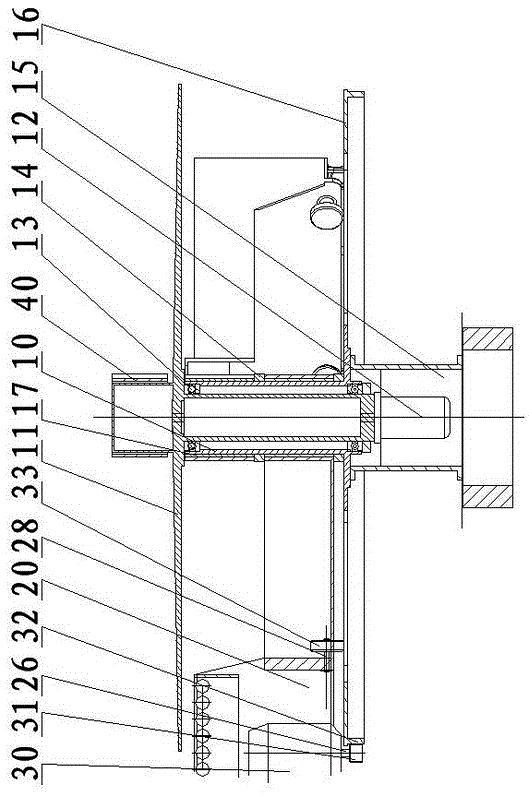

[0020] Such as figure 1 , figure 2 , image 3 As shown, the turntable transition type two-way loading and unloading machine of the present invention is composed of a carrying trolley 1, an intermediate conveyor 2, a belt conveyor 1 3, a belt conveyor 2 6, a material blocking device 4 and a control system 5 thereof. The carrying trolley 1 is used as the carrying and traveling mechanism of the whole machine and has a walking function to realize the walking and transition of the mobile loading and unloading machine. Intermediate conveyor 2, belt conveyor 1 3, belt conveyor 2 6, and blocking device 4 constitute a loading and unloading mechanism; intermediate conveyor 2 can realize the transitional transportation of items between the two belt conveyors, and can guide and change the logistics Direction; Belt Conveyor 1 3 and Belt Conveyor 2 6 are respectively used as feeding conveyor and unloading conveyor to realize the loading and unloading of items; the orientation and posture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com