Track type ultrasonic detecting device for large ring member and ring member detecting method

An ultrasonic testing, track-type technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problems of low detection efficiency of rings and reduce the surface area Blind area, high detection accuracy, and the effect of improving the detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

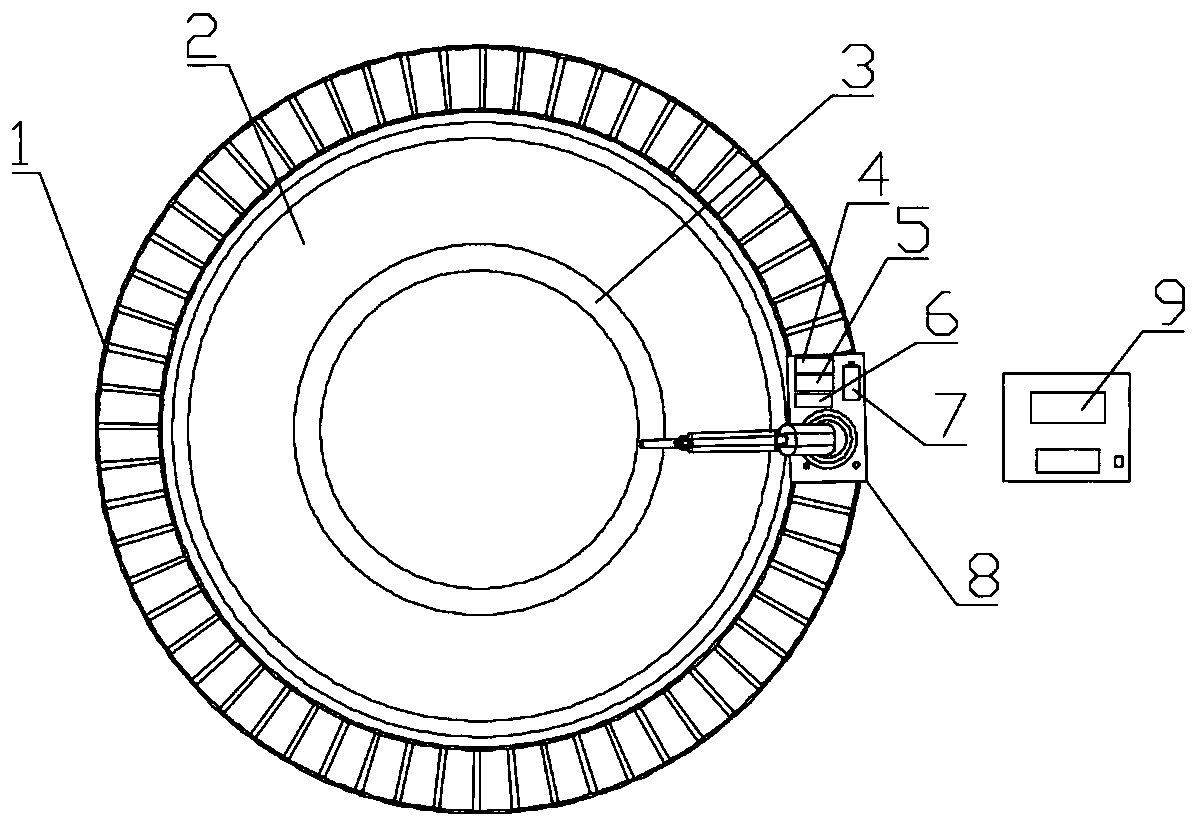

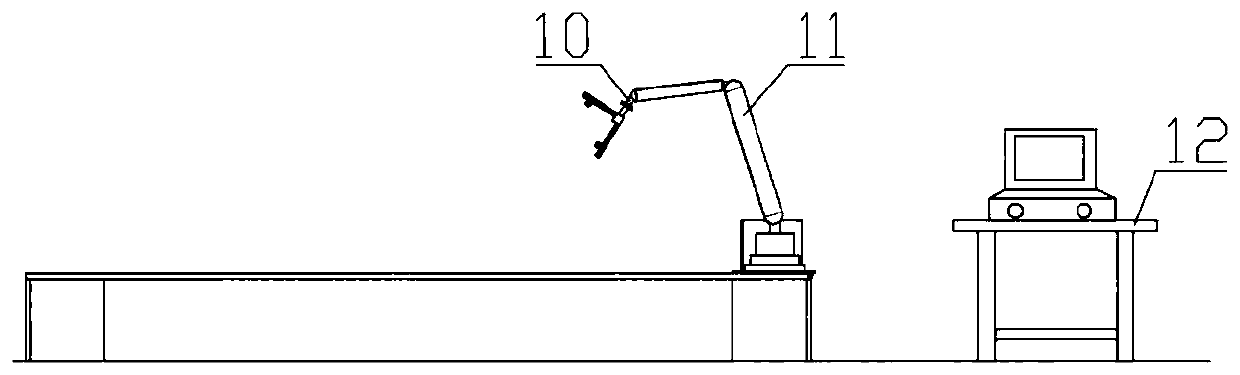

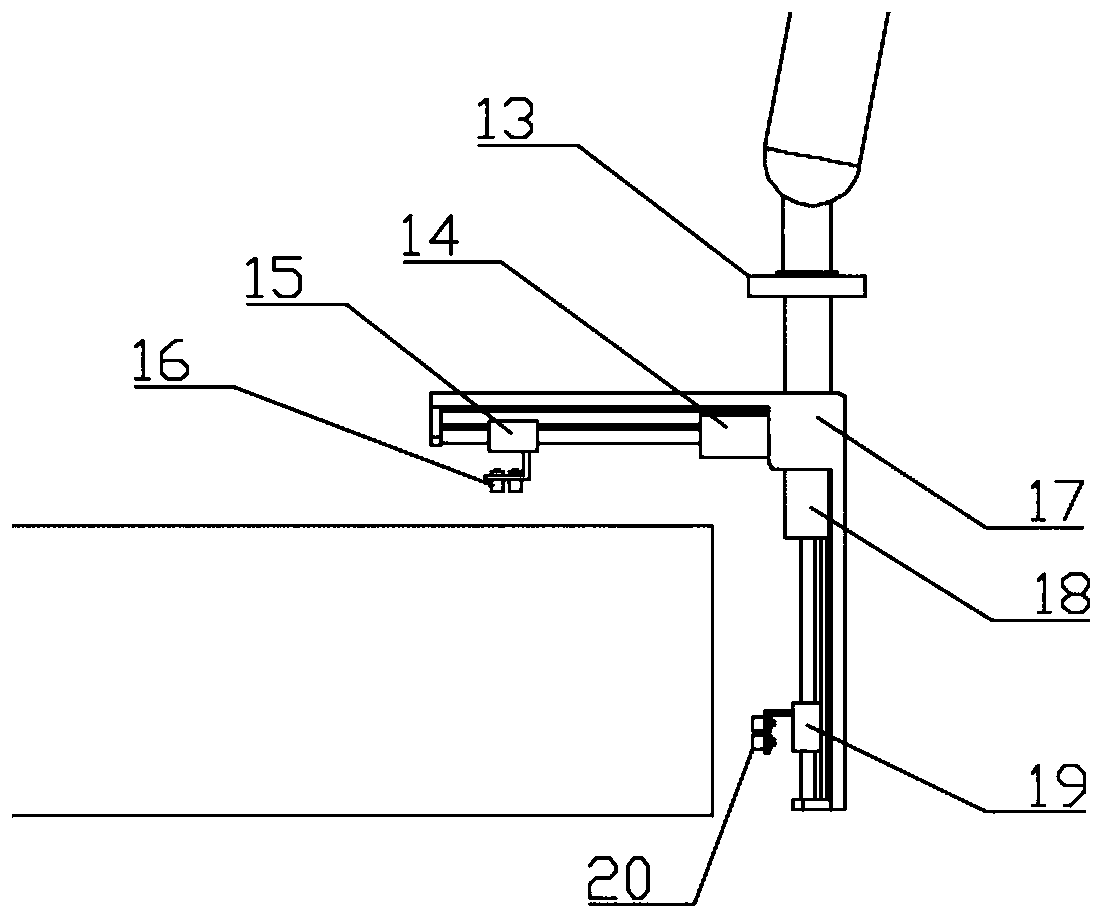

[0056] Please refer to figure 1 , with reference to Figure 2 to Figure 3 , the embodiment of the present application provides an orbital ultrasonic testing device for large rings 3, which is aimed at large forgings with a detection range of 100-300 mm.

[0057] The orbital ultrasonic testing device for large rings 3 mainly includes a pool 2 with coupling agent, a circular track 1, an industrial robot 11, a drive assembly, and an ultrasonic scanning mechanism; the pool 2 is provided with a large ring 3. A circular track 1 is provided around the pool 2; the industrial robot 11 is movably installed on the circular track 1, and the drive assembly is connected to the industrial robot 11 for driving the industrial robot 11 to move on the circular track 1 ; The ultrasonic scanning mechanism is installed on the end effector 10 of the industrial robot 11 for detecting internal defects of the large ring 3 .

[0058] It should be noted that in this embodiment, the couplant is water; i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com