Caisson type high-pile seawall and construction method thereof

A caisson-type, high-pile technology, applied in caisson, jetty, embankment and other directions, can solve the problems of high construction cost, poor overall strength and stability, reduce construction cost, high construction efficiency, and improve anti-overturning ability and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

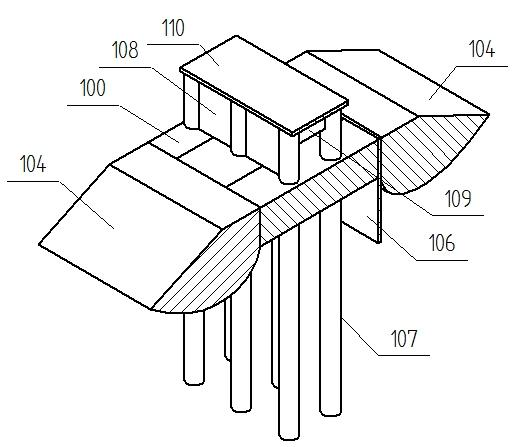

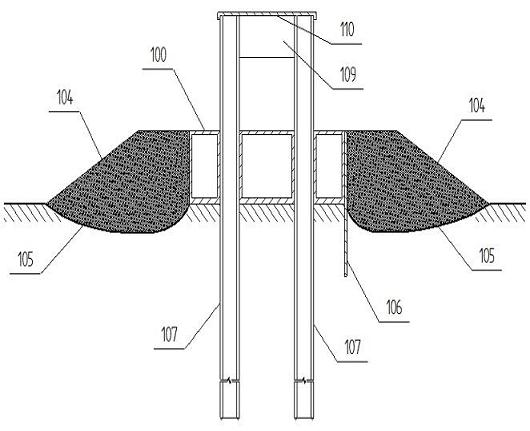

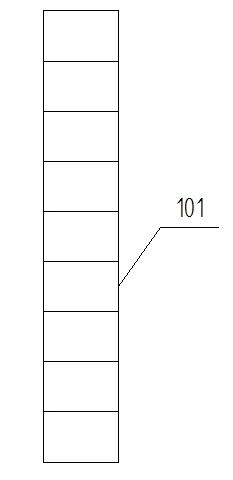

[0042] Such as figure 1 and figure 2 As shown, a caisson-type high-pile seawall includes a caisson platform 100 located on a shallow seabed soft soil foundation, and the caisson platform is spliced by a plurality of reinforced concrete boxes 101, such as image 3 As shown, the quantity of the box body 101 is determined by the design length of the seawall, and the box body 101 is a hollow cuboid structure, such as Figure 4 As shown, the box body 101 is provided with a reserved piling sleeve 102 that runs through its upper and lower surfaces. One side of the box body 101 in the width direction has a protruding connecting portion that protrudes outward, and the other side has an inward concave The recessed connection part that enters, the structure of box body 101 is as follows Figure 5 and Figure 6 As shown, the two adjacent boxes 101 are spliced by the protruding connection part and the concave connection part. At the same time, steel plates are pre-embedded on the e...

Embodiment 2

[0053] Such as Figure 8 Shown, a kind of caisson type high pile seawall, its difference with embodiment 1 is: box body 101 comprises left box 101a and right box 101b, as Figure 9 , Figure 10 and Figure 11 As shown, if the design of the seawall is relatively wide, and it is relatively difficult to manufacture a box 101 or it is inconvenient to move, then the left box 101a and the right box 101b are spliced, and the left box 101a and the right box 101b are spliced. There are reserved pile-forming sleeves 102 penetrating through the upper and lower surfaces respectively.

[0054] The seawall construction method in Embodiment 2 is different from Embodiment 1 in that: the left box 101a and the right box 101b are spliced into a box body 101, and the rest is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com