Optical detection method for plate material forming and springback

An optical detection and sheet material technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of difficult to accurately measure the rebound amount and physical expression, and achieve the effect of reducing the handling cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

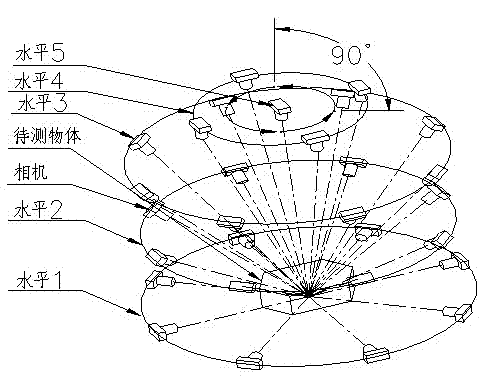

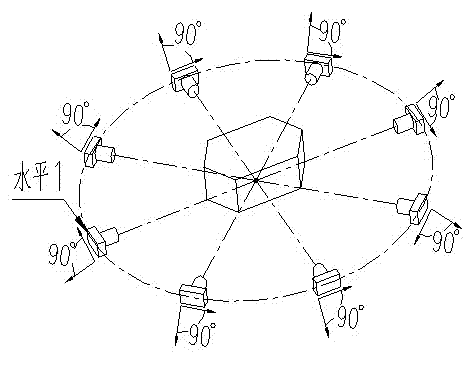

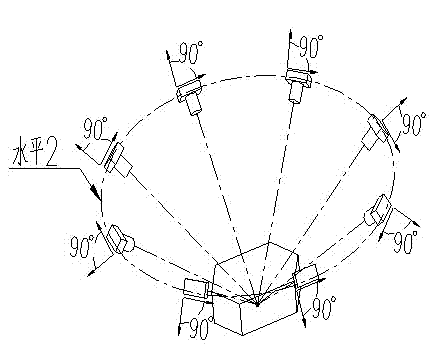

Method used

Image

Examples

Embodiment 1

[0056] The research object is taken from the BC-48 refrigerator door shell of a famous domestic appliance company, such as Figure 7 As shown, BC-48 is a small type refrigerator, and its door shell is made of thin plate, and the material used in production is black work, with a thickness of 0.6 mm. Spray plastic after forming to ensure the appearance. Apply the detection and evaluation method proposed in this paper to obtain the geometric shape of the refrigerator door shell, its cross-sectional shape after forming and the designed mold CAD digital model are aligned and compared, and the three-dimensional springback value of different parts and directions of the two can be obtained.

[0057] The experimental steps are as follows:

[0058] (1) Arrange coded markers, non-coded markers and scales around the workpiece to be measured;

[0059] (2) Take photos, and the photogrammetry system calculates the coded points and non-coded points on the surface of the door shell, such as ...

Embodiment 2

[0079] The measurement example is the rear floor longitudinal beam (500 mm×300 mm×100 mm) of a certain model of car. Figure 14-18The measurement procedure for the rear floor rail of a car is shown. The photogrammetry system calculates the three-dimensional coordinate matrix of all non-coded points by pasting coded and non-coded points on the surface of the workpiece and placing the Invar alloy scale. Based on the derived non-coding marker point matrix; the surface scanning system scans the geometric features of the workpiece surface to obtain a point cloud group that can represent the complete geometric information of the workpiece. After performing operations such as deletion, thinning, and denoising on overlapping surfaces, they are merged to obtain the final point cloud. The point cloud was input into the Geomagic Qualify software and set as the test object. The mathematical model of the workpiece is copied through features in Pro / E to obtain the surface shape of its out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com