Glass plate packing method and packing structure

A packaging method and packaging structure technology, which is applied in the field of glass plate packaging and packaging structure, can solve the problems that synthetic paper is easy to break and is not suitable for reuse, and achieve the effect of reducing handling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

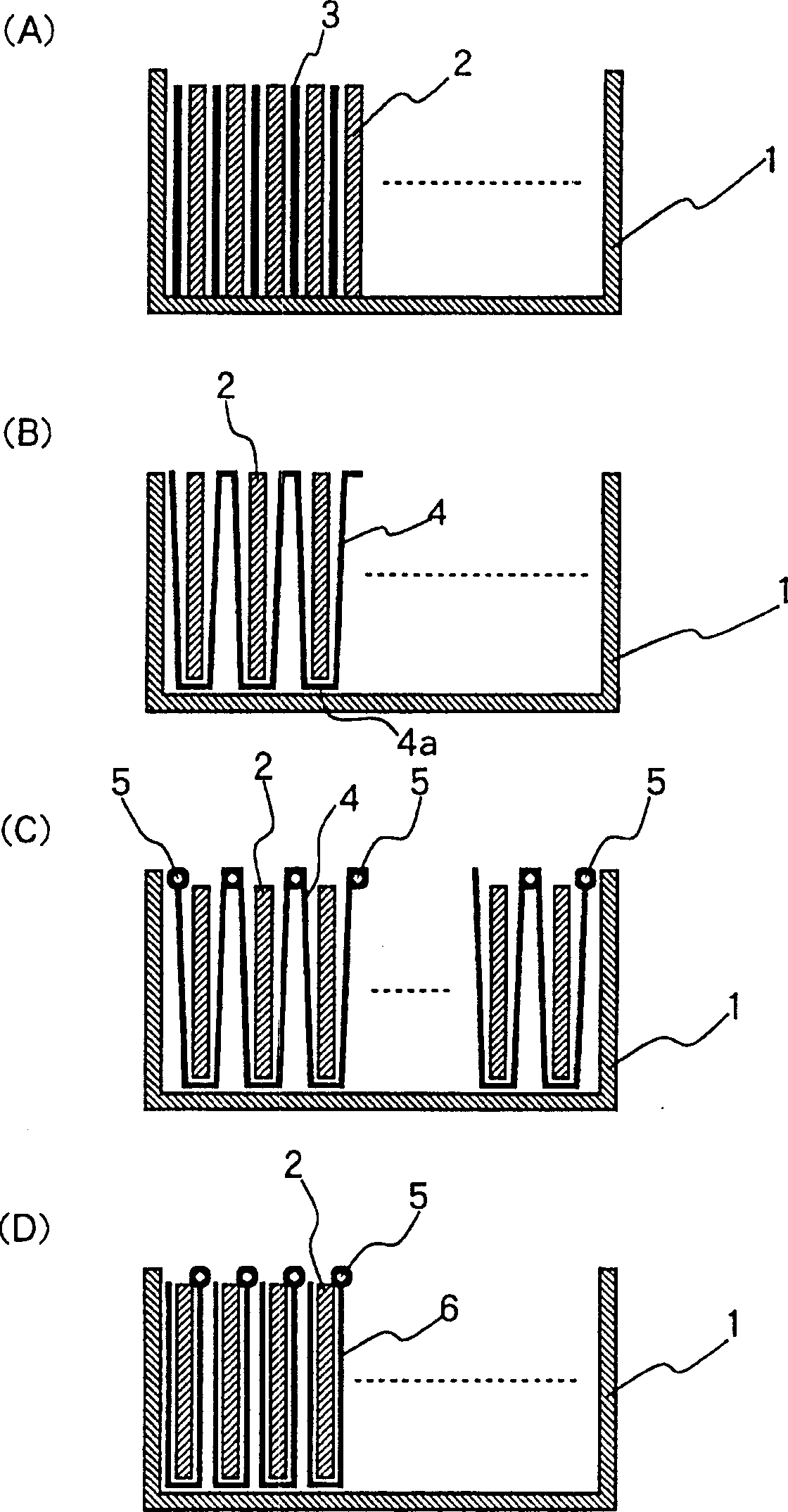

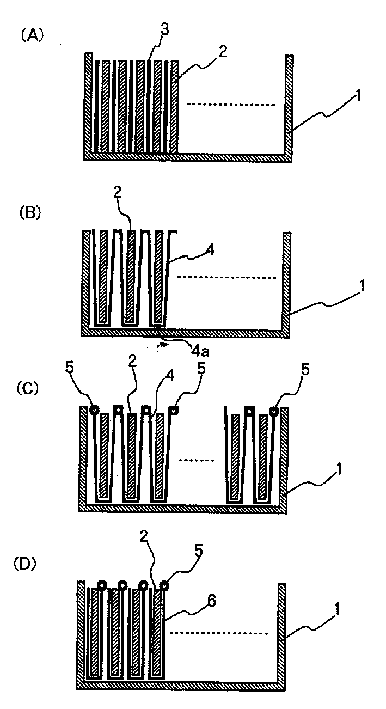

[0010] Hereinafter, the glass plate packaging method of the present invention will be described with reference to the accompanying drawings. figure 1 (A)~(D) are cross-sectional views illustrating the packaging method and packaging structure of the glass plate of the present invention. Each figure will be described below.

[0011] First, if figure 1 As shown in (A), in the box-shaped container 1 which has an opening on the upper surface, several glass plates 2 are vertically loaded. The container 1 is a lightweight container made of resin such as polypropylene.

[0012] Between each glass plate 2, spacer (insert) is equipped with the spacer 3 that buffer usefulness. The partition plate 3 has a rectangular shape conforming to the inner shape of the container 1, thereby separating one glass plate from another. Therefore, when the glass plates 2 are transported in the container 1, the contact between the glass plates 2 can be prevented.

[0013] In addition, the thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com