Preparation method of strawberry type organic-inorganic composite particles

A composite particle, strawberry-type technology, applied in the field of synthesis of strawberry-type organic-inorganic composite particles, can solve the problems of increased difficulty in purification, preparation of organic-inorganic composite nanoparticles, increased production costs, etc., to achieve separation and versatility , Ease of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

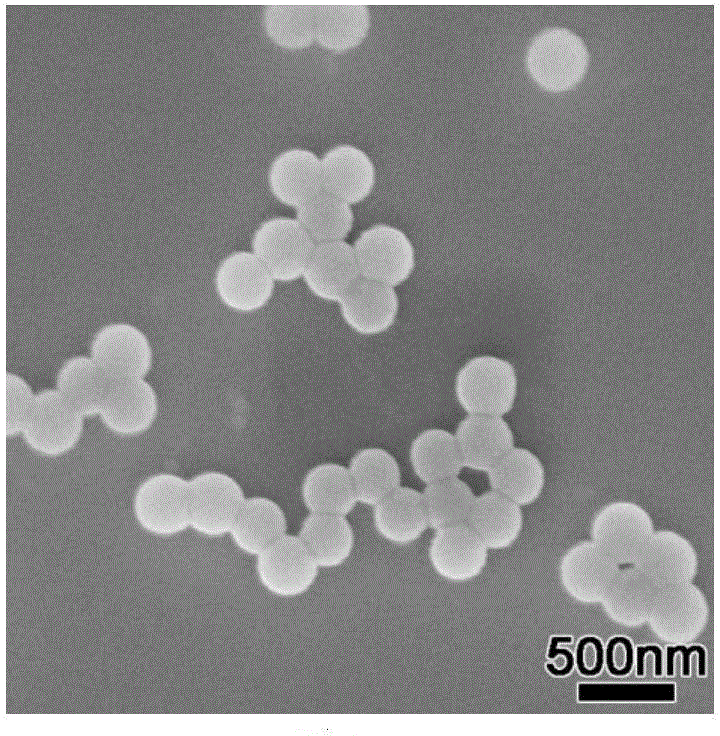

[0032] Implementation Case 1 Preparation of Strawberry Type PVC / ZnO Composite Particles

[0033]

[0034]

[0035]

[0036] In a 2L autoclave, add 6.0g hydrophilic monomer acetoacetoxyethyl methacrylate (AAEM), 600.0g deionized water, 0.72g potassium persulfate, seal the autoclave, repeatedly vacuumize and fill nitrogen three times, Ensure that the atmosphere before the reaction is nitrogen, the pressure is normal pressure, start stirring, set the stirring speed to 300r / min, add 60.0g of template monomer vinyl chloride (VC) after stirring for 15 minutes, and quickly heat up to the reaction temperature of 55°C after stirring for 15 minutes , stop the reaction when the pressure drops to 0.25MPa, depressurize (vacuum about 0.0995MPa) to remove the unreacted vinyl chloride monomer, and then obtain the PVC stencil emulsion. Immediately, the emulsion sample was taken directly, and the morphology of the PVC template particles was observed with a scanning electron microscope....

Embodiment example 2-5

[0044] The addition amount of the hydrophilic monomer AAEM of the implementation case 2-5 is 0g, 3g, 9g, 12g respectively, and the rest of the implementation process is the same as the implementation case 1, and the SEM photos of the composite particle forms prepared by the implementation case 2-5 are shown in Appendix 4 -7.

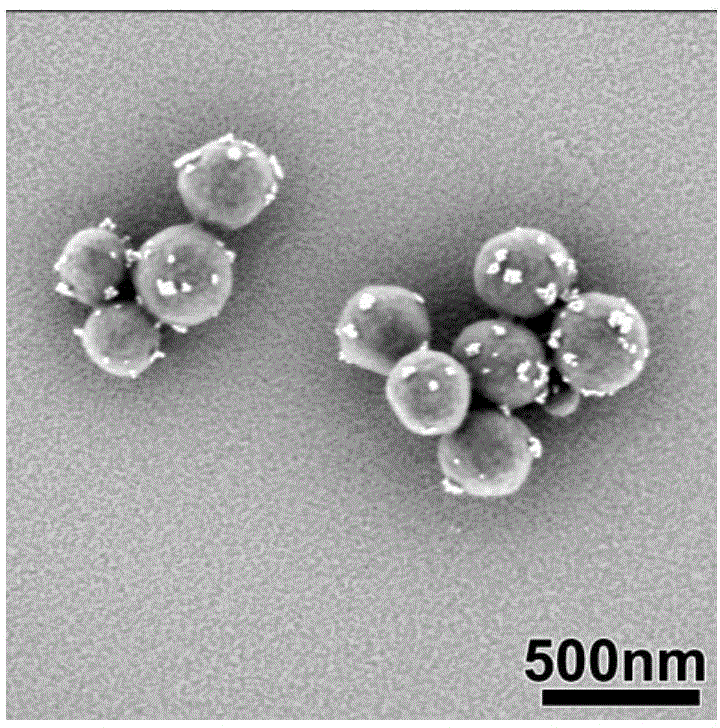

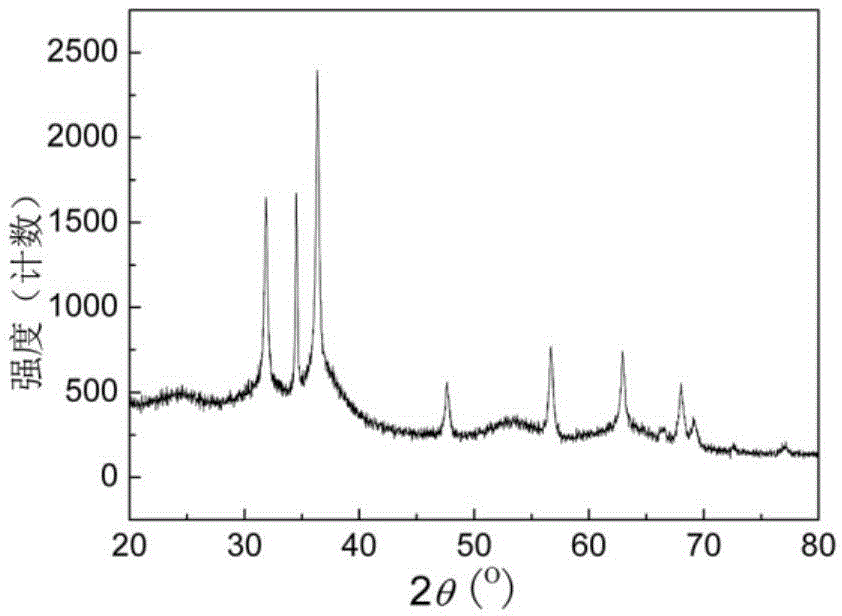

[0045] Depend on Figure 4-6 SEM photos can be observed, ZnO nanoparticles deposited on the PVC template to form a strawberry. ZnO crystals are spherical with a diameter of 20-50nm. With the increase of AAEM content, the number of nano-ZnO particles on the surface of the stencil increases. Depend on Figure 7 It can be seen that when the content of AAEM reaches 20wt% of the template monomer, the core-shell morphology of ZnO crystals incompletely covering the template particles is formed.

[0046] The change of ZnO morphology and content with the change of AAEM content is explained as follows: the zinc oxide precursor interacts with the stencil latex ...

Embodiment example 6-7

[0049] In Example 6-7, the amount of sodium hydroxide added is 0.04g and 0.08g respectively, that is, the corresponding concentration is 0.5mol L -1 , 1.0mol·L -1 . The added volume remains the same as 2mL, and the rest of the implementation process is the same as that of Example 1. The SEM photo of the composite particle form prepared by implementation case 6-7 is attached Figure 8-9 .

[0050] Analyzing the above: Implementation Cases 6-7, in the reaction medium of isopropanol, NaOH plays an important role in the nucleation and growth process of ZnO. Figure 8-9 SEM photographs of the morphology of composite particles prepared for Example 6-7. It can be seen from the figure that zinc oxide nanoparticles are evenly attached to the surface of PVC latex particles at any concentration, presenting a strawberry-like specific shape. Not only that, as the concentration of NaOH increases from 0.5mol·L -1 Increased to 1.0mol·L -1 , more and more zinc oxide particles are attach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com