Method for producing sodium sulfide by suspending sodium sulfate

A sodium sulfate and sodium sulfide technology, applied in the direction of alkali metal sulfide/polysulfide, can solve the problems of low production efficiency and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

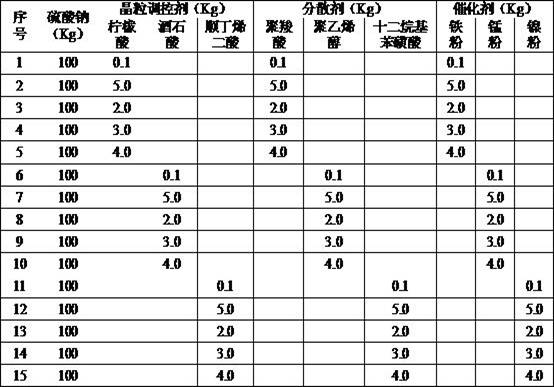

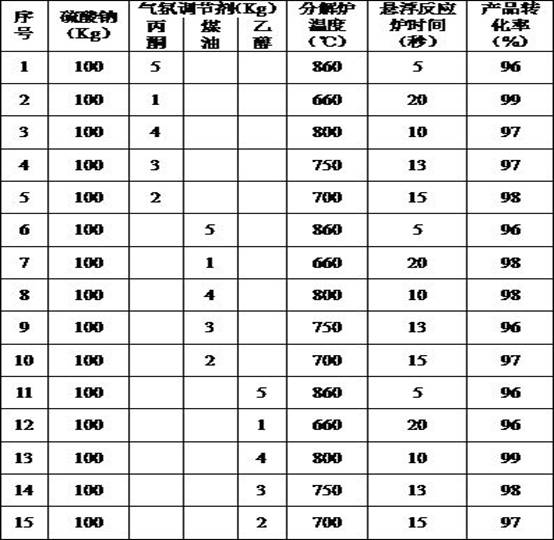

[0017] The present invention will be described in further detail below in conjunction with specific examples. Add grain control agent and dispersant to sodium sulfate saturated solution, concentrate, crystallize and dry to obtain superfine sodium sulfate powder; add catalyst to sodium sulfate powder and mix evenly, then add to suspension reaction furnace to react to obtain product Mixture, the product mixture is sorted to obtain sodium sulfide. The following table shows the formulations of grain control agent, dispersant and catalyst, see Table 1. See Table 2 for the atmosphere modifier, temperature, reduction time and product conversion rate of the calciner.

[0018] Table 1

[0019]

[0020] Table 2

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com