Method for preparing nano silver powder

A technology of nano-silver powder and silver nitrate, which is applied in the field of preparation of nano-silver powder, can solve the problems of high production cost, difficult process control, and high difficulty of industrialization, and achieve the effects of improving productivity, facilitating washing, and reducing washing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

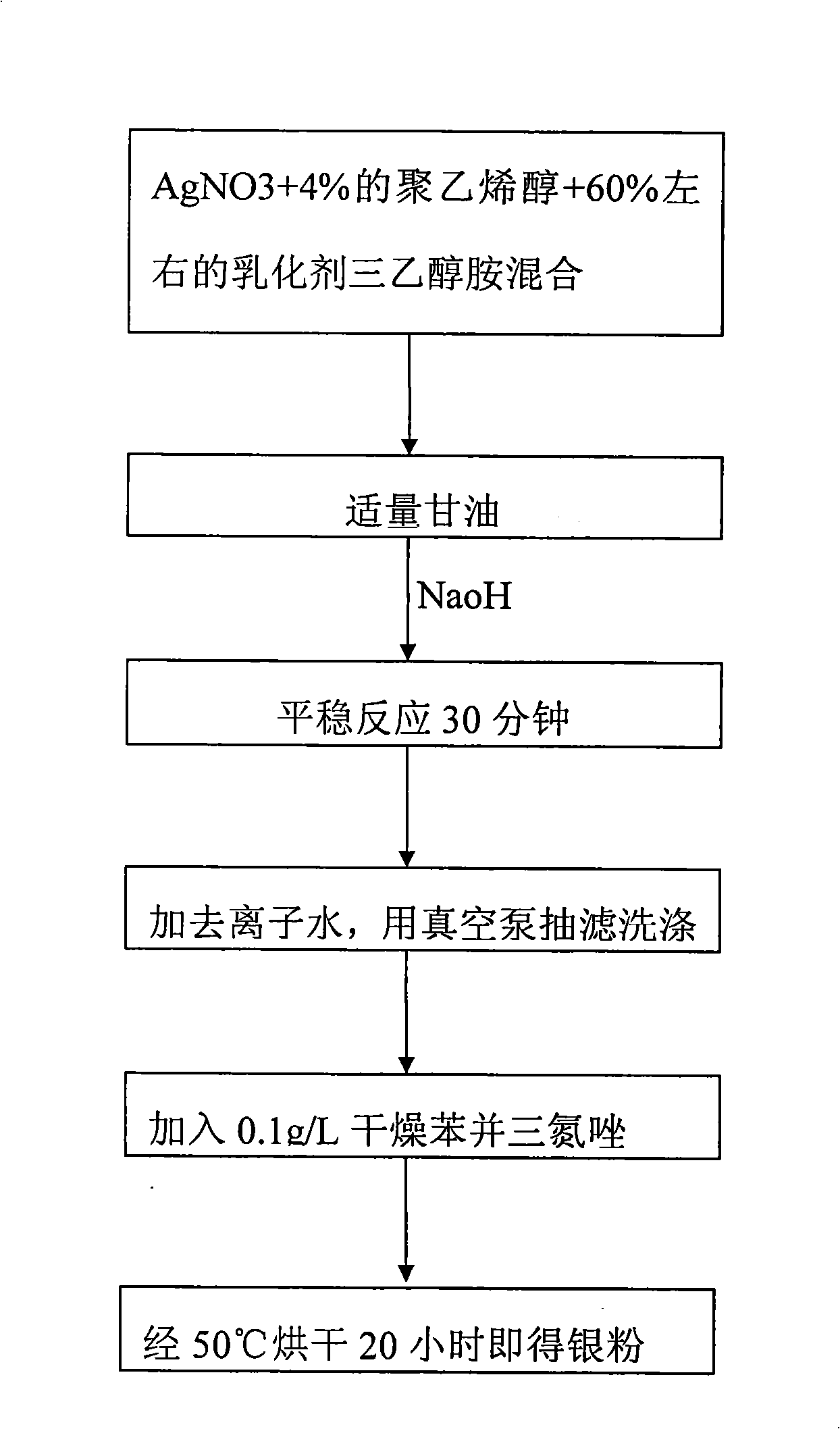

Image

Examples

Embodiment 1

[0024] A preparation method of nanometer silver powder, it comprises the following steps:

[0025] a. 30g of solid silver nitrate and polyvinyl alcohol with a mass concentration of 3% are prepared into a 1.6mol / L silver nitrate solution, and then 6ml of emulsifier triethanolamine with a mass concentration of about 56% is added to fully emulsify it;

[0026] b. After it is fully emulsified, add 20ml of reducing agent glycerin, stir evenly, and then add 37ml of activator NaoH solution with a mass concentration of about 13%;

[0027] c. Adjust the reaction temperature to 26°C, adjust the stirring speed to 56 rpm, and make the reaction run smoothly for 30 minutes;

[0028] d. After the reaction is completed, add an appropriate amount of deionized water, and use a vacuum pump to filter and wash for 5 to 6 times;

[0029] e. Then dehydrate with absolute ethanol;

[0030] f. After dehydration, add 0.1g / L drying protectant benzotriazole 22ml;

[0031] g. After drying at 50°C for 20...

Embodiment 2

[0033] A preparation method of nanometer silver powder, it comprises the following steps:

[0034] a. 40g of solid silver nitrate and polyvinyl alcohol with a mass concentration of 5% are formulated into a silver nitrate solution of 2.0mol / L, and then 6ml of emulsifier triethanolamine with a mass concentration of about 64% is added to make it fully emulsified;

[0035] b. After it is fully emulsified, add an appropriate amount of 40ml of reducing agent glycerin, stir evenly, and then add 44ml of activator NaoH solution with a mass concentration of about 17%;

[0036] c. Adjust the reaction temperature to 33°C, adjust the stirring speed to 74 rpm, and make the reaction run smoothly for 30 minutes;

[0037] d. After the reaction is completed, add an appropriate amount of deionized water, and use a vacuum pump to filter and wash for 5 to 6 times;

[0038] e. Then dehydrate with absolute ethanol;

[0039] f. After dehydration, add 0.1g / L desiccation protection agent benzotriazol...

Embodiment 3

[0042] A preparation method of nanometer silver powder, it comprises the following steps:

[0043] a. 35g of solid silver nitrate and polyvinyl alcohol with a mass concentration of 4% are mixed with a silver nitrate solution of 1.8mol / L, then adding 6ml of emulsifier triethanolamine with a mass concentration of about 60% to make it fully emulsified;

[0044] b. After it is fully emulsified, add 30ml of reducing agent glycerin, stir evenly, and then add 40ml of activator NaoH solution with a mass concentration of 15%;

[0045] c. Adjust the reaction temperature to 27°C, adjust the stirring speed to 60 rpm, and make the reaction run smoothly for 30 minutes;

[0046] d. After the reaction is completed, add an appropriate amount of deionized water, and use a vacuum pump to filter and wash for 5 to 6 times;

[0047] e. Then dehydrate with absolute ethanol;

[0048] f. After dehydration, add 0.1g / L desiccation protection agent benzotriazole 35ml;

[0049] g. After drying at 50°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com