Fe3O4 nano-microsphere and preparation method thereof

A nano-microsphere, face-centered cubic technology, applied in the field of nanomaterials, can solve the problems of complex preparation process, limited product types, difficult to control, etc., and achieve the effects of rapid preparation, good magnetic properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Fe 3 o 4 The preparation of nano microspheres comprises the following steps:

[0035] (1) FeCl 2 and FeCl 3 Dissolve in deionized water at a molar ratio of 1:2;

[0036] (2) in N 2 Under a protected environment, heat the solution obtained in step 1 to 75°C, add 1 mol / L NaOH solution dropwise to the mixed solution, adjust the pH value to 11, and stir vigorously for 2 hours to obtain Fe without polymer wrapping 3 o 4 ;

[0037] (3) Add 0.1g / mL polyethyleneimine to obtain the Fe of the present invention through modification 3 o 4 nanospheres;

[0038] (4) Use a magnet to displace the Fe obtained in step 3 3 o 4 The nano-microspheres are separated, and then dissolved in deionized water under the action of ultrasonic waves, and washed repeatedly for 5 to 20 times.

[0039] (5) The washed Fe 3 o 4 Nanospheres were dissolved in deionized water to obtain Fe 3 o 4 nanosphere solution.

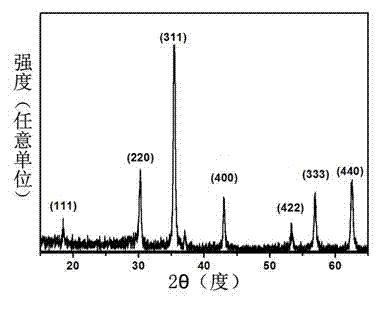

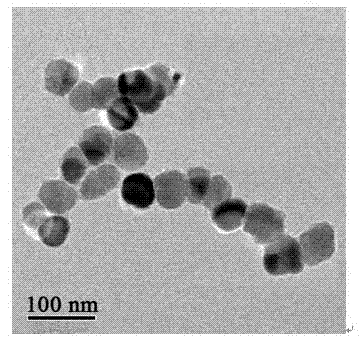

[0040] Such as figure 1 Shown, X-ray diffraction test shows, the prepared F...

Embodiment 2

[0042] The temperature of step 2 is 90 ℃, all the other are identical with embodiment 1.

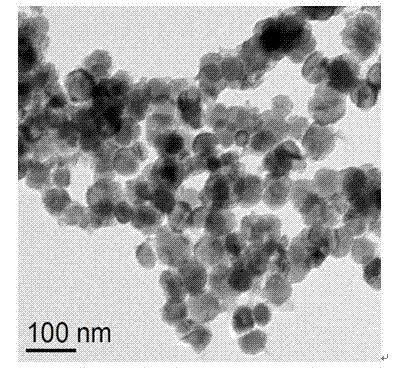

[0043] Such as image 3 As shown, Fe 3 o 4 The nanospheres showed good dispersion, the particle size was 50 nm–60 nm, and the obtained Fe 3 o 4 Nanospheres including Fe 3 o 4 A face-centered cubic structure and a polyethyleneimine layer wrapping its surface. Among them, Fe 3 o 4 The particle size of the nanospheres is 50 nm–60 nm, and the thickness of the polyethyleneimine layer is 0.5–2 nm.

[0044] Comparing Example 1 and Example 2, it can be found that Fe 3 o 4 The particle size of nano-microspheres is related to the set reaction temperature. When the temperature rises, the particle radius also becomes larger. The preferred reaction temperature of the preparation method of the present invention is 70°C to 80°C, which can prepare Fe with good dispersibility, uniform particle size, about 45-55 nm in size, and polyethyleneimine modification of about 1 nm on the surface. 3 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com