Metal-oxide mixed-phase titanium-chromium brown pigment and preparation process thereof

A technology of oxide, titanium chromium brown, applied in inorganic pigment treatment, fibrous filler, dyeing physical treatment, etc., can solve the problems of high price, out of stock, unstable quality and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

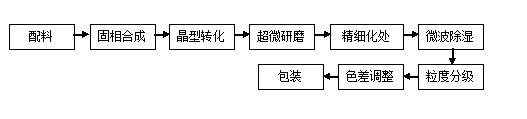

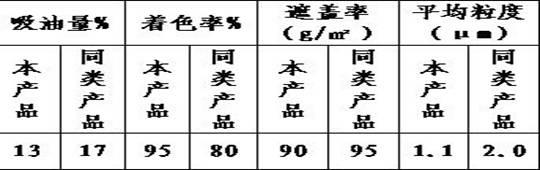

Method used

Image

Examples

Embodiment Construction

[0032] The metal oxide mixed-phase titanium chromium brown pigment of the present invention has the following components in terms of important percentages: 81-86.5% of titanium dioxide, 5.2-6.5% of dichromium trioxide, 9.5-11.0% of antimony trioxide, and 0.15-0.25% of lithium fluoride , sodium tetraborate 0.15-0.18%, potassium carbonate 0.10-0.15%, rare earth oxide 0.25-0.35%, cerium oxide 0.15-0.25%, rubidium oxide 0.05-0.15%.

[0033] The metal oxide mixed-phase titanium chromium brown pigment of the present invention has the following components in terms of important percentages: 82.72% titanium dioxide, 6.2% chromium trioxide, 10.3% antimony trioxide, 0.18% lithium fluoride, 0.17% sodium tetraborate, carbonic acid Potassium 0.13%, cerium oxide 0.20%, rubidium oxide 0.10%.

[0034] In the above formula, lithium fluoride, sodium tetraborate, potassium carbonate, cerium oxide, and rubidium oxide are all additives, and their functions are as follows: lithium fluoride, embedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com