Preparation of binary alloy nanowire direct alcohol fuel cell catalyst

A binary alloy and fuel cell technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, battery electrode, etc., can solve the problem of alcohol fuel transmission obstruction and nanoscale catalyst metal particle poisoning , High cost of catalyst preparation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

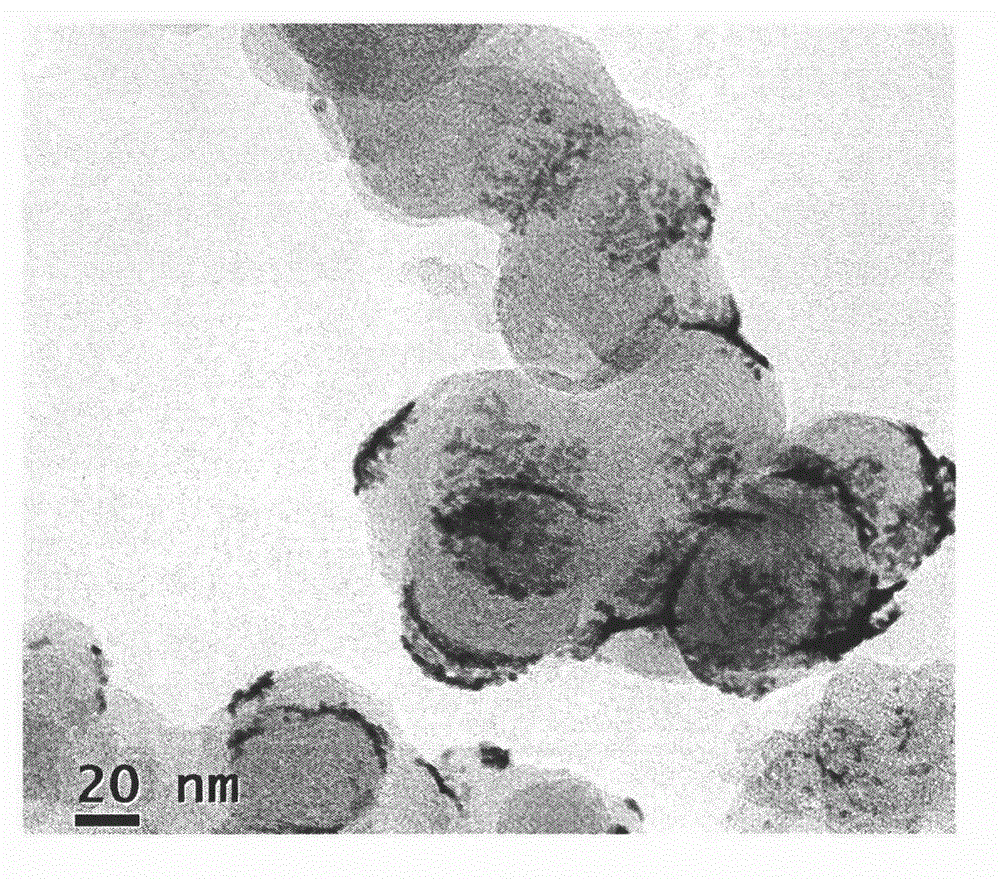

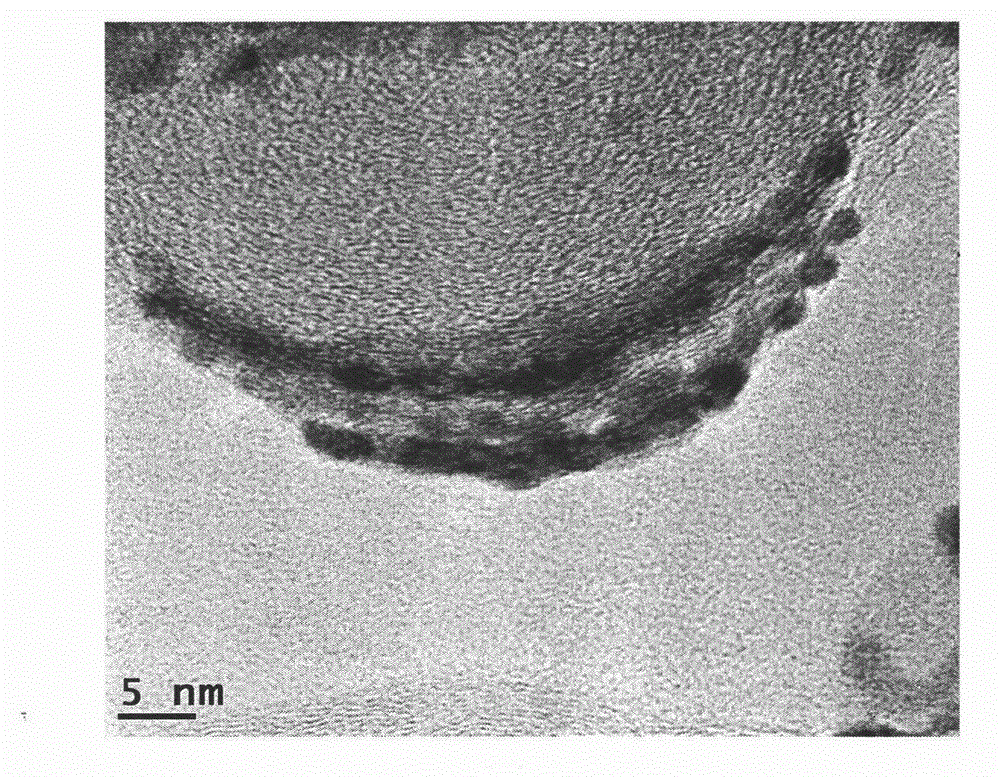

Image

Examples

specific Embodiment approach 1

[0007] Specific embodiment one: the preparation method of binary alloy nanowire structure direct alcohol fuel cell catalyst in the present embodiment is to realize according to the following steps: one, cationic surfactant and carrier are dissolved in polyhydric alcohol and polar solvent, ultrasonic Mechanical stirring after treatment to obtain a uniform mixture, the concentration of the anionic surfactant in the mixture is 0.5 to 3 times the critical micelle concentration, the carrier is XC-72 carbon black, carbon nanotubes, graphene, mesoporous carbon or carbon fiber, the cationic surfactants include dodecyl dimethyl tertiary amine acetate, cetyl trimethyl ammonium bromide, heterocyclics such as imidazoline, morpholine guanidine, triazine One of derivatives; 2. Add metal precursor salts and complexes to the above mixture sequentially according to 20% to 60% of the total loading of metal elements in metal precursor salts and complexes to form a mixed slurry, wherein The metal...

specific Embodiment approach 2

[0009] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the polyhydric alcohol described in step one is ethylene glycol, propylene glycol, glycerol, 1,3-butanediol or pentaerythritol; the polar solvent is benzene, Toluene, xylene, carbon disulfide, ether, chloroform. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment differs from Embodiments 1 to 3 in that the atomic ratio of the metal precursor salt and the metal element in the complex in step 2 is 1:1. Other steps and parameters are the same as those in the first to third specific embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com