Process for preparing 20,23-bi-piperidyl-5-O-carbon mould amine glycosyl-tylosin lactone

A mycaminoglycosyl and tylonolide technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of many by-products, cumbersome reaction steps and high cost, and achieve simplified production. Process, high purity, easy industrial application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

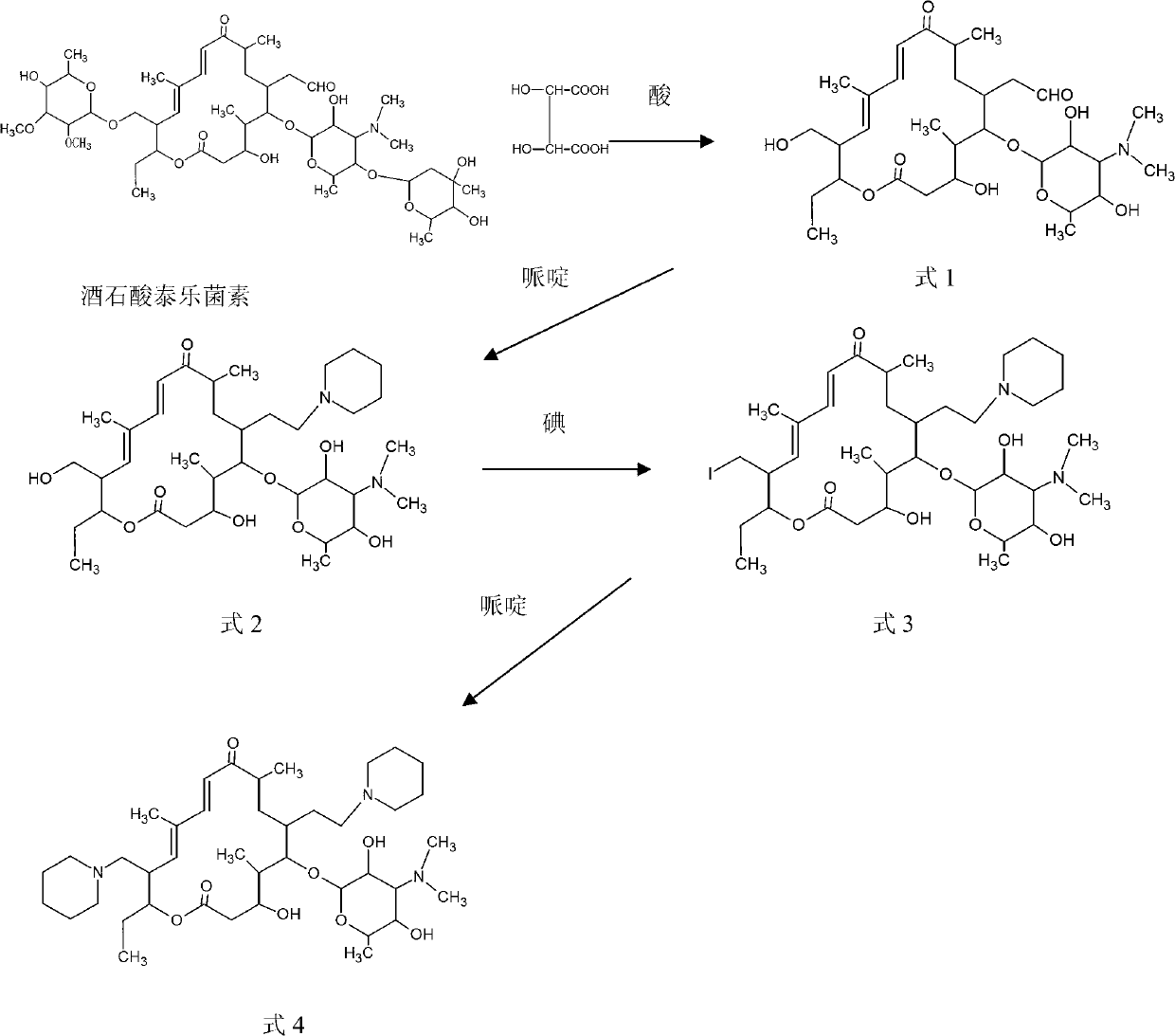

[0046] A preparation method of 20,23-dipiperidinyl-5-O-mycaminosyl-tylonolide, the steps are as follows:

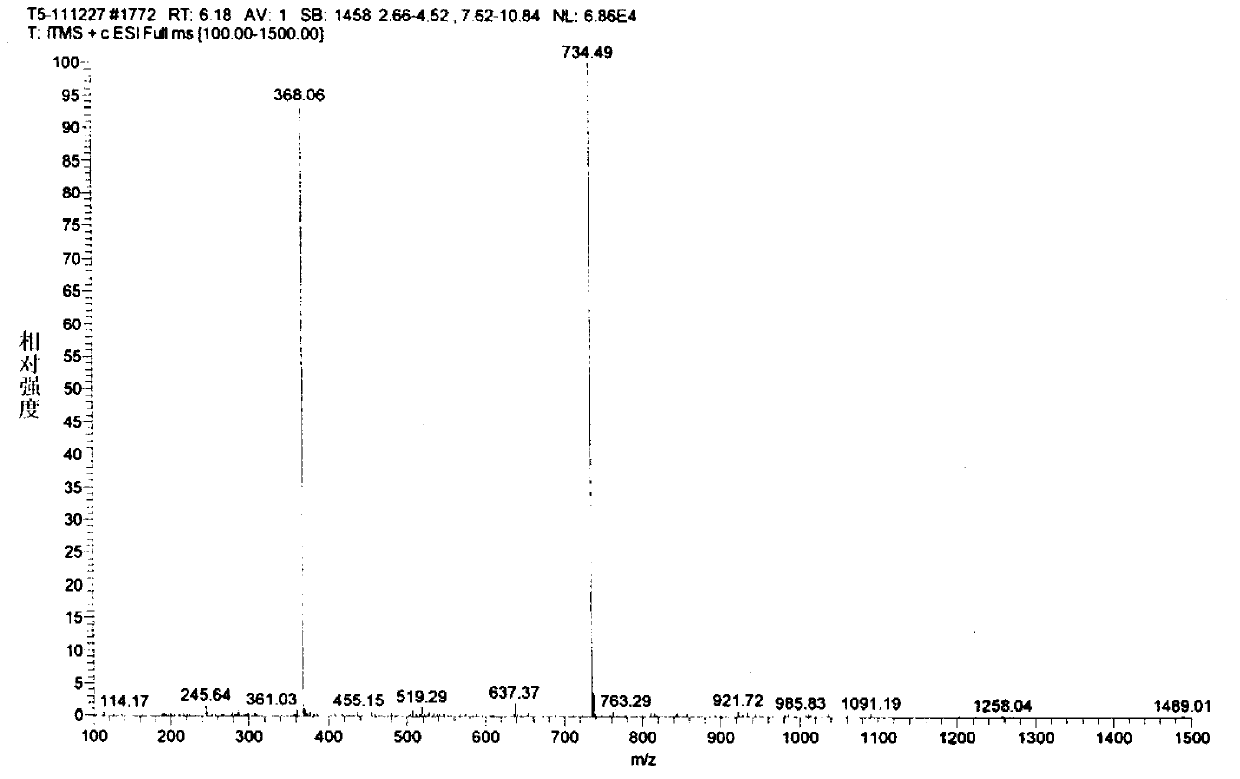

[0047] (1) Dissolve 300kg of tylosin tartrate in 4500kg of purified water, then add 741.6kg of sulfuric acid with a mass percentage of 20% while keeping the temperature at 50°C, and hydrolyze for 8 hours. The peak of tylosin detected by HPLC completely disappears. Detected by HPLC, 150kg of 23-hydroxyl-5-O-mycaminosyl-tylonolide was obtained, with a molar yield of 82.8%;

[0048] (2) Add 755 kg of dichloromethane to the 150 kg reaction liquid containing 23-hydroxy-5-O-mycaminosyl-tylonolactone prepared in step (1), and adjust the pH with 5 mol / L sodium hydroxide solution When the value reaches 8, separate layers, take the organic layer, add 21.5kg of piperidine, 11.5kg of anhydrous formic acid, heat to 40°C, reflux for 5h, and detect 23-hydroxy-5-O-mycaminosyl-Taylor by HPLC The lactone content is less than 2g / L, and 149kg of 20-piperidinyl-23-hydroxy-5-O-mycaminosyl-tyl...

Embodiment 2

[0053] A preparation method of 20,23-dipiperidinyl-5-O-mycaminosyl-tylonolide, the steps are as follows:

[0054] (1) Dissolve 300kg of tylosin tartrate in 5400kg of purified water, then add 370.8kg of sulfuric acid with a mass percentage of 40% at a temperature of 80°C, and hydrolyze for 6 hours. The peak of tylosin detected by HPLC completely disappears. Detected by HPLC, 151 kg of 23-hydroxyl-5-O-mycaminosyl-tylonolide was obtained, with a molar yield of 83.4%;

[0055] (2) Add 755kg of dichloromethane to the 151kg reaction liquid containing 23-hydroxy-5-O-mycaminosyl-tylonolactone prepared in step (1), and adjust the pH with 5mol / L sodium hydroxide solution When the value reaches 10, separate layers, take the organic layer, add 25.8kg of piperidine, 13.8kg of anhydrous formic acid, heat to 40°C, reflux for 5.5h, and detect 23-hydroxy-5-O-mycaminosyl-Thai by HPLC The content of tylonolide is less than 2g / L, and 155kg of 20-piperidinyl-23-hydroxyl-5-O-mycaminosyl-tylonolide...

Embodiment 3

[0060] A preparation method of 20,23-dipiperidinyl-5-O-mycaminosyl-tylonolide, the steps are as follows:

[0061] (1) Dissolve 300kg of tylosin tartrate in 6000kg of purified water, then add 302kg of sulfuric acid with a mass percentage of 98% while keeping the temperature at 90°C, and hydrolyze for 6 hours. The peak of tylosin detected by HPLC disappears completely. Detected and obtained 130 kg of 23-hydroxy-5-O-mycaminosyl-tylonolide, with a molar yield of 71.8%;

[0062] (2) Add 755 kg of dichloromethane to the 130 kg reaction liquid containing 23-hydroxy-5-O-mycaminosyl-tylonolactone prepared in step (1), and adjust the pH with 5 mol / L sodium hydroxide solution When the value reaches 12, separate layers, take the organic layer, add 43kg of piperidine, 26kg of anhydrous formic acid, heat to 40°C, reflux for 6h, and detect the content of 23-hydroxy-5-O-mycaminosyl-tylonolide by HPLC Less than 2g / L, 138kg of 20-piperidinyl-23-hydroxyl-5-O-mycaminosyl-tylonolide was obtained;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com