Method for preparing Silicalite-1/ZSM-5 composite molecular sieve

A technology of ZSM-5 and composite molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of low solid product yield, increased production cost, complicated steps, etc., and achieves industrial application, high production efficiency, and coverage uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

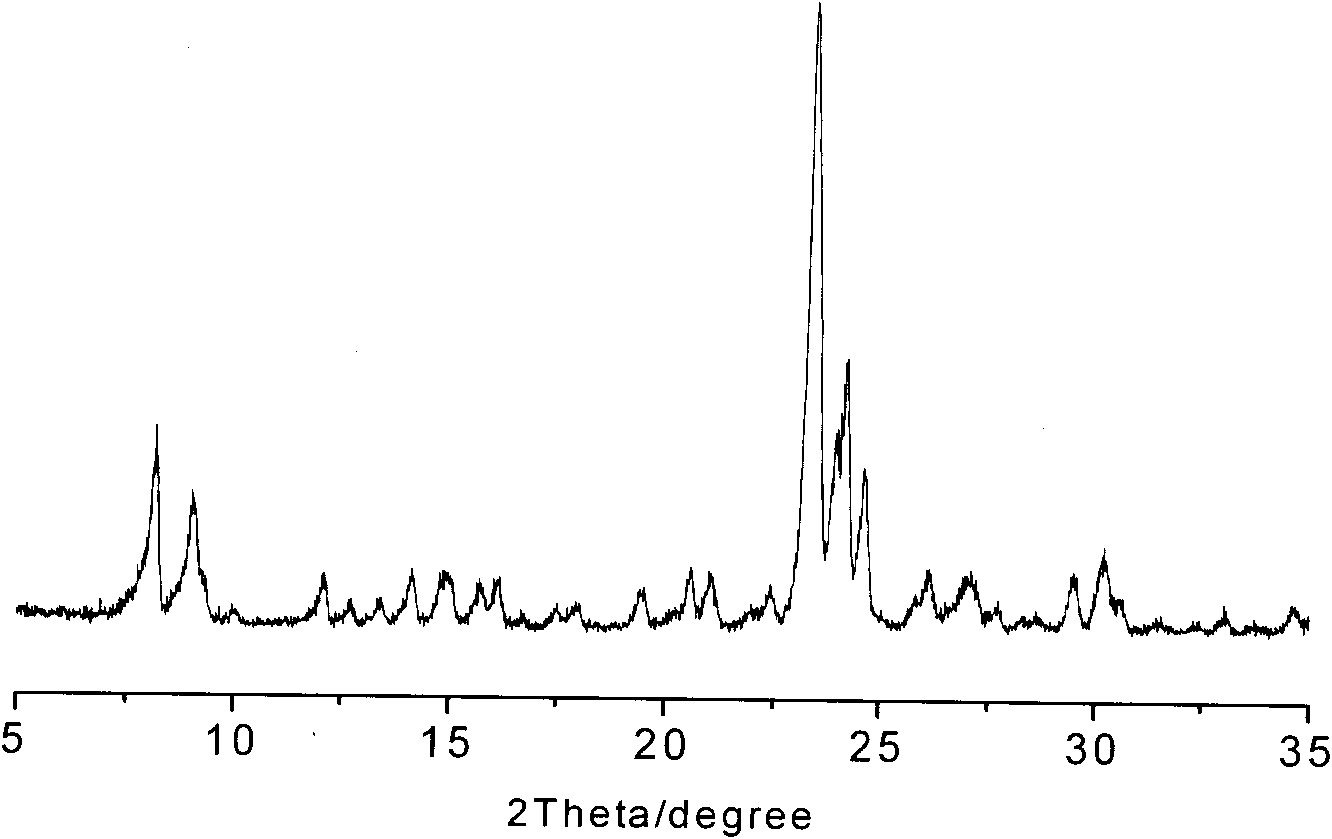

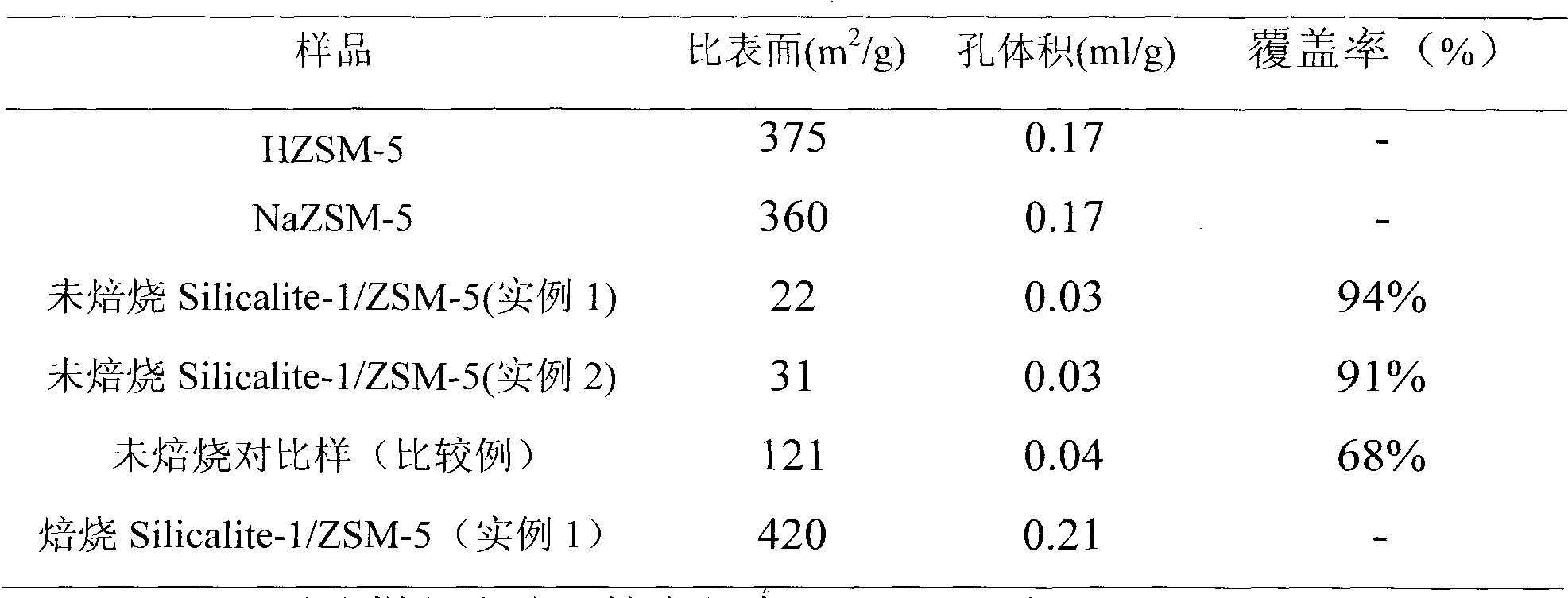

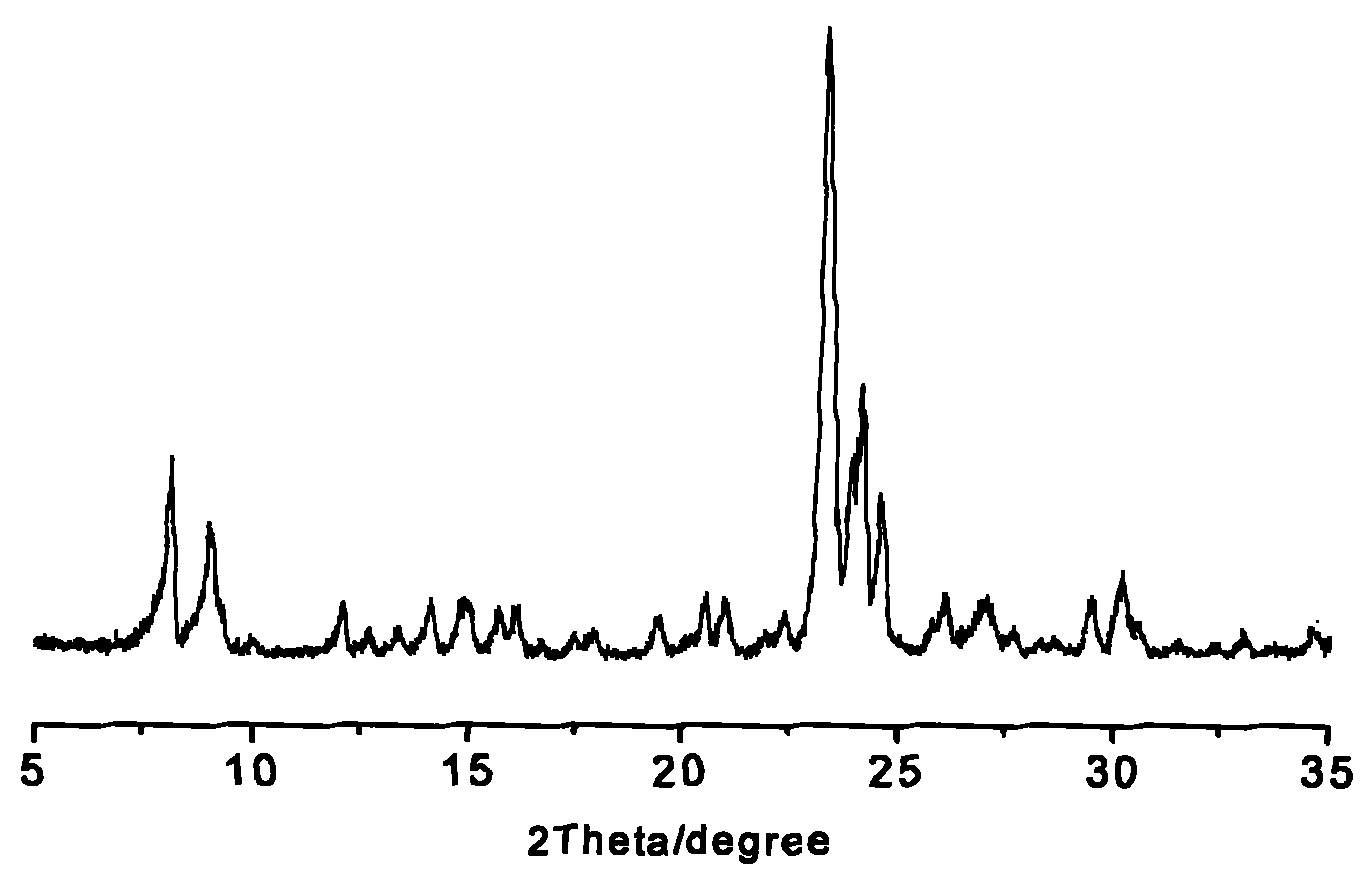

[0015] Add 3.6 g of sodium hydroxide to 25.0 ml of deionized water, weigh 16.0 g of tetrapropylammonium bromide and add it to the sodium hydroxide solution, and weigh 7.5 g of NaZSM-5 molecular sieve into the solution after it is completely dissolved, and stir for half After 1 hour, add 50.0ml of silica sol, stir evenly, put it into a stainless steel crystallization kettle, and crystallize at a constant temperature of 150°C for 18 hours, then wash, dry, and roast to obtain a composite molecular sieve.

Embodiment approach 2

[0017] Add 3.6 g of sodium hydroxide to 55.0 ml of deionized water, weigh 16.0 g of tetrapropylammonium bromide and add it to the sodium hydroxide solution, after it is completely dissolved, weigh 5.0 g of NaZSM-5 molecular sieve and add it to the solution, stir for half After 1 hour, add 20.0ml of silica sol, stir evenly, put it into a stainless steel crystallization kettle, and crystallize at a constant temperature of 100°C for 12 hours, then wash, dry, and roast to obtain a composite molecular sieve.

Embodiment approach 3

[0019] Add 3.6 g of sodium hydroxide to 25.0 ml of deionized water, weigh 16.0 g of tetrapropylammonium bromide and add it to the sodium hydroxide solution. After it is completely dissolved, weigh 7.5 g of HZSM-5 molecular sieve and add it to the solution, stir for half After one hour, add 50.0ml of silica sol, stir evenly, put it into a stainless steel crystallization kettle, and crystallize at a constant temperature of 180°C for 24 hours, then wash, dry, and roast to obtain a composite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com