Compound type cement-based permeable crystallization type waterproof material

A technology of osmotic crystallization and waterproof materials, which is applied in the field of building waterproof materials, can solve problems such as the inability to use green building materials, easy aging, decomposition, degradation, and environmental hazards of flexible waterproof materials, and achieve excellent self-repairing functions, excellent waterproof and anti-seepage, and improved The effect of the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

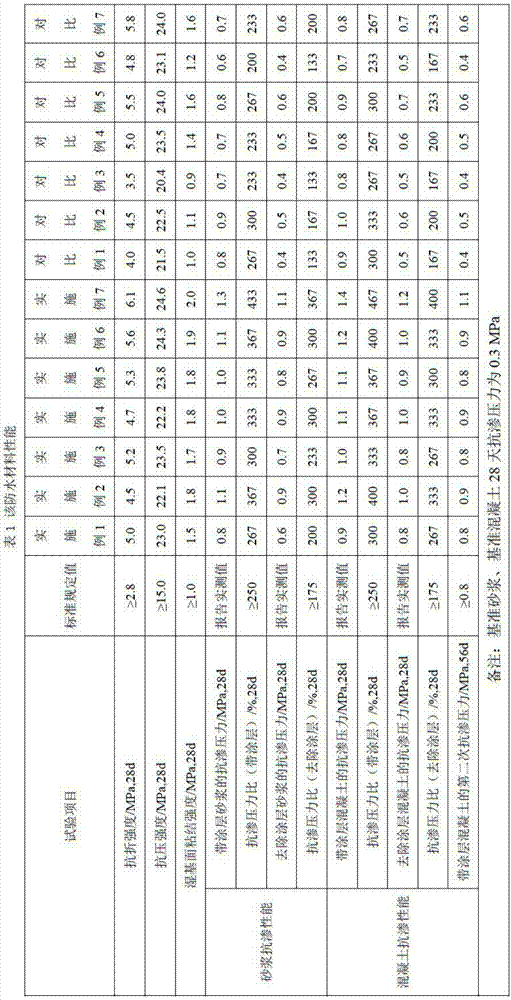

Examples

Embodiment 1

[0053]This embodiment provides a composite cement-based permeable crystalline waterproof material, which is composed of the following raw materials in proportion by weight:

[0054] Portland cement: 320 parts;

[0055] Quartz sand: 240 parts;

[0056] Heavy calcium: 60 parts;

[0057] Silica fume: 5 parts;

[0058] Redispersible latex powder: 2 parts;

[0059] Surfactant: 0.5 parts;

[0060] Catalyst: 0.5 parts;

[0061] Cellulose ether: 0.05 parts.

[0062] Wherein, the ratio of the surfactant in parts by weight is specifically: polycarboxylate: polyethylene glycol: octadecanoic acid salt = 5: 12: 83; the redispersible latex powder is vinyl chloride-ethylene-vinyl laurate ester terpolymer; the catalyst is formate; the cellulose ether is hydroxyethyl methyl cellulose ether with a viscosity of 200-1300mPa·s; the quartz sand is composed of 50-100 mesh quartz sand and 70-140 mesh quartz sand The compound weight ratio is specifically: 50-100 mesh quartz sand: 70-140 mesh qu...

Embodiment 2

[0064] This embodiment provides a composite cement-based permeable crystalline waterproof material, which is composed of the following raw materials in proportion by weight:

[0065] Portland cement: 570 parts;

[0066] Quartz sand: 480 parts;

[0067] Heavy calcium: 250 parts;

[0068] Silica fume: 150 parts;

[0069] Redispersible latex powder: 125 parts;

[0070] Surfactant: 50 parts;

[0071] Catalyst: 30 parts;

[0072] Cellulose ether: 2 parts.

[0073] Wherein, the ratio of the surfactant in parts by weight is specifically: polycarboxylate: polyethylene glycol: octadecanoic acid salt = 10:22:68; the redispersible latex powder is vinyl chloride-ethylene-vinyl laurate ester terpolymer; the catalyst is formate; the cellulose ether is hydroxyethyl methyl cellulose ether with a viscosity of 200-1300mPa·s; the quartz sand is composed of 50-100 mesh quartz sand and 70-140 mesh quartz sand The compound weight ratio is specifically: 50-100 mesh quartz sand: 70-140 mesh qu...

Embodiment 3

[0075] This embodiment provides a composite cement-based permeable crystalline waterproof material, which is composed of the following raw materials in proportion by weight:

[0076] Portland cement: 360 parts;

[0077] Quartz sand: 265 parts;

[0078] Heavy calcium: 75 parts;

[0079] Silica fume: 15 parts;

[0080] Redispersible latex powder: 7 parts;

[0081] Surfactant: 1 part;

[0082] Catalyst: 1 part;

[0083] Cellulose ether: 0.1 parts.

[0084] Wherein, the ratio of the surfactant in parts by weight is specifically: polycarboxylate: polyethylene glycol: octadecanoic acid salt = 6:14:80; the redispersible latex powder is vinyl chloride-ethylene-vinyl laurate ester terpolymer; the catalyst is formate; the cellulose ether is hydroxyethyl methyl cellulose ether with a viscosity of 200-1300mPa·s; the quartz sand is composed of 50-100 mesh quartz sand and 70-140 mesh quartz sand The compound weight ratio is specifically: 50-100 mesh quartz sand: 70-140 mesh quartz sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com