Bio-degradable polyester and method for preparing same

A technology for biodegradable polyester and derivatives is applied in the field of biodegradable polyester and its preparation, and can solve the problems of low mechanical properties, low melting point, and the inability of biodegradable polyester resin materials to meet preparation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Add 330kg of 1,5-pentanediol and 175kg of dimethyl terephthalate into the reactor, under the protection of nitrogen, raise the temperature to 185°C, add 319g of n-butyl titanate, and maintain the temperature in the reactor at 190°C, After reacting for 4 hours, 161 kg of azelaic acid was added and reacted at 200° C. for 4 hours.

[0073] Then, the temperature was raised to 210° C., and after reacting in a low vacuum (90 KPa) for 1 hour, 200 g of n-butyl titanate was added. After the temperature reaches 230°C, react for 30 minutes, then start to slowly raise the temperature to 245°C, gradually increase the vacuum degree, so that the pressure in the kettle reaches 1KPa, keep the temperature constant, and keep the pressure in the kettle below 80Pa, and react for 3.5 hours to obtain the product .

[0074] The relevant indicators of the product were obtained: molecular weight: Mn=38860, Mw=67500, viscosity 1.18dL / g, carboxyl end 50mol / t, melting point 113.8°C, 90-day degrada...

Embodiment 2

[0076] Add 300kg of 1,4-butanediol, 140kg of dimethyl terephthalate, and 640g of glycerin into the reactor, under the protection of nitrogen, raise the temperature to 170°C, add 350g of n-butyl titanate, and maintain the temperature in the reactor After reacting for 4 hours, add 210kg of adipic acid and react at 200°C for 4 hours.

[0077] Then, the temperature was raised to 210° C., and after reacting in a low vacuum (90 KPa) for 1 hour and 40 minutes, 200 g of n-butyl titanate was added. After the temperature reaches 230°C, react for 30 minutes, then start to slowly raise the temperature to 245°C, gradually increase the vacuum degree, so that the pressure in the kettle reaches 1KPa, keep the temperature constant, and keep the pressure in the kettle below 80Pa, and react for 3.5 hours to obtain the product .

[0078] The product-related indicators were obtained: molecular weight: Mn=56490, Mw=112850, viscosity 1.27dL / g, carboxyl-terminated group 75mol / t, melting point 124.0°...

Embodiment 3

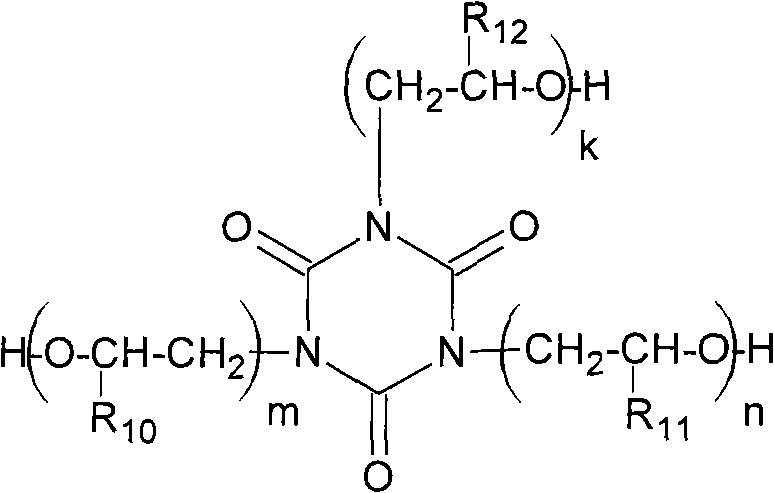

[0080] Add 290kg of isosorbide, 170kg of dimethyl terephthalate, and 1200g of trimesic acid into the reaction kettle. Under the protection of nitrogen, heat up to 180°C, add 450g of n-butyl titanate, and maintain the temperature in the reaction kettle at After reacting for 4.5 hours at 200°C, add 170kg of succinic acid and react at 210°C for 4 hours. Add 2 kg of tris(2-hydroxyethyl)isocyanurate.

[0081] Then, the temperature was raised to 220° C., and after reacting in a low vacuum (90 KPa) for 1 hour, 200 g of n-butyl titanate was added. After the temperature reaches 230°C, react for 30 minutes, slowly raise the temperature to 245°C, gradually increase the vacuum degree to make the pressure in the kettle reach 1KPa, keep the temperature constant, keep the pressure in the kettle below 80Pa, and react for 3.5 hours to obtain the product.

[0082] The relevant indicators of the obtained product are: molecular weight Mn=49380, Mw=102170, viscosity 1.25dL / g, carboxyl terminal 64...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com