Method for green environmental-protection preparation of high-concentration ultra-clean graphene dispersion liquid

A graphene dispersion, green and environmental protection technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as the inability to achieve large-scale production requirements, increase the cost of ionic liquid preparation, and increase the cost of graphene, To achieve the effect of convenient large-scale industrial production, low production cost and few defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

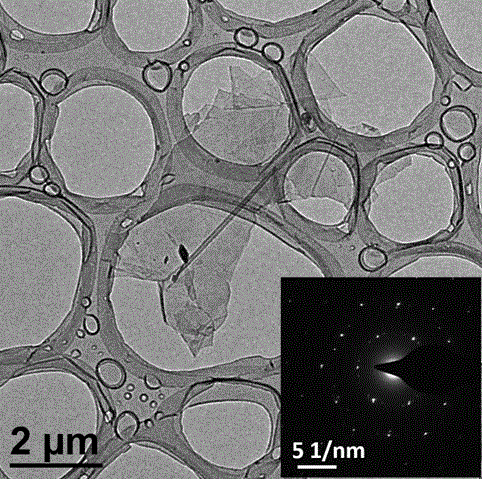

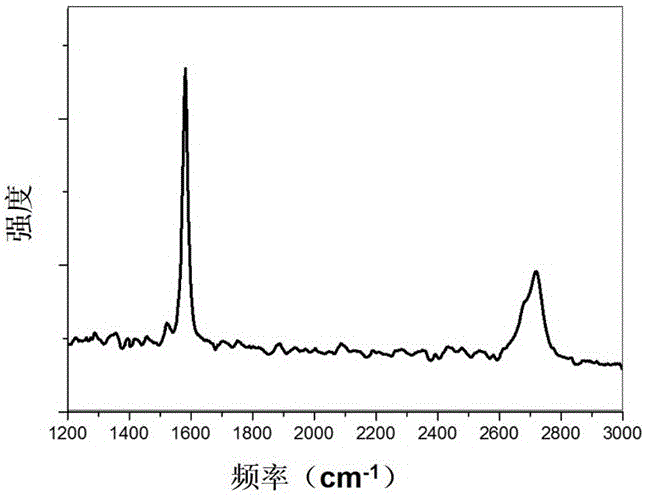

[0024] 50mL of concentrated sulfuric acid, 10g of ammonium persulfate and 10mL of deionized water were mixed and stirred at 5°C for 10 minutes, 1g of flake graphite was added, and after continuous stirring in a 20°C water bath for 24h, expanded graphite was obtained. After washing and filtering with water, add 50mL of 1-ethyl-3-methylimidazolium tetrafluoroborate, and ultrasonically treat for 2h to obtain a viscous high-concentration graphene dispersion with a concentration of 16mg / mL, such as figure 1 shown. from figure 2 From the results of transmission electron microscope (TEM), it can be seen that the method realizes the sufficient exfoliation of graphene, and the obtained graphene has few layers, and the yield is more than 90%. from figure 2 The selected area electron diffraction (SAED) pattern obtained and image 3 Raman spectrum (Raman) shows that the obtained graphene does not introduce defects, has a complete lattice structure, and its film conductivity is 1100S / ...

Embodiment 2

[0026] 50mL of concentrated sulfuric acid, 10g of ammonium persulfate and 10mL of deionized water were mixed and stirred at 5°C for 10 minutes, 1g of flake graphite was added, and after continuous stirring in a 20°C water bath for 24h, expanded graphite was obtained. After washing and filtering with water, add 50mL of 1-ethyl-3-methylimidazolium tetrafluoroborate, and process it with a high-speed shear for 2h at a speed of 13000rpm to obtain a viscous high-concentration graphene dispersion with a concentration of 16mg / mL, such as figure 1 shown. The obtained graphene is few layers, and the yield is more than 90%. Moreover, the resulting graphene does not introduce defects, has a complete lattice structure, and its film conductivity is 1000 S / cm.

Embodiment 3

[0028] 50mL of concentrated sulfuric acid, 10g of ammonium persulfate and 10mL of deionized water were mixed and stirred at 5°C for 10 minutes, 1g of flake graphite was added, and after continuous stirring in a 20°C water bath for 24h, expanded graphite was obtained. After washing and filtering with water, 50 mL of 1-ethyl-3-methylimidazolium tetrafluoroborate was added, and then ball milled at 1000 rpm for 10 h to obtain a viscous high-concentration graphene dispersion with a concentration of 16 mg / mL. The obtained graphene is few layers, and the yield is more than 90%. Moreover, the resulting graphene does not introduce defects, has a complete lattice structure, and its film conductivity is 1000 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com