Extrusion port die for preparing alternate multiple high polymer composite material

A composite material and extrusion port technology, which is applied in the field of polymer material lamination processing, can solve the problems of high design accuracy requirements, leakage of interlayer materials, complex structure design, etc. Maintenance-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

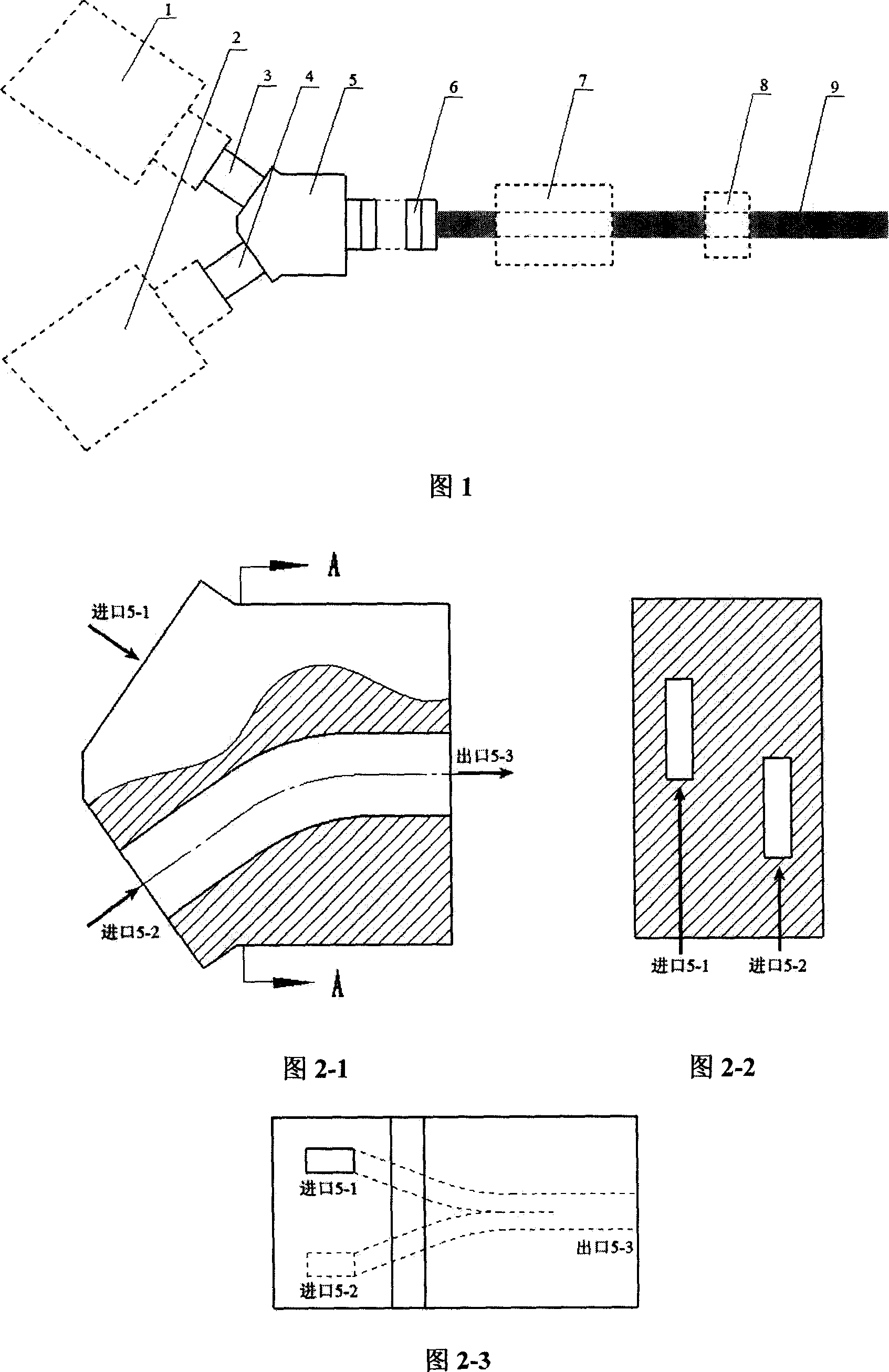

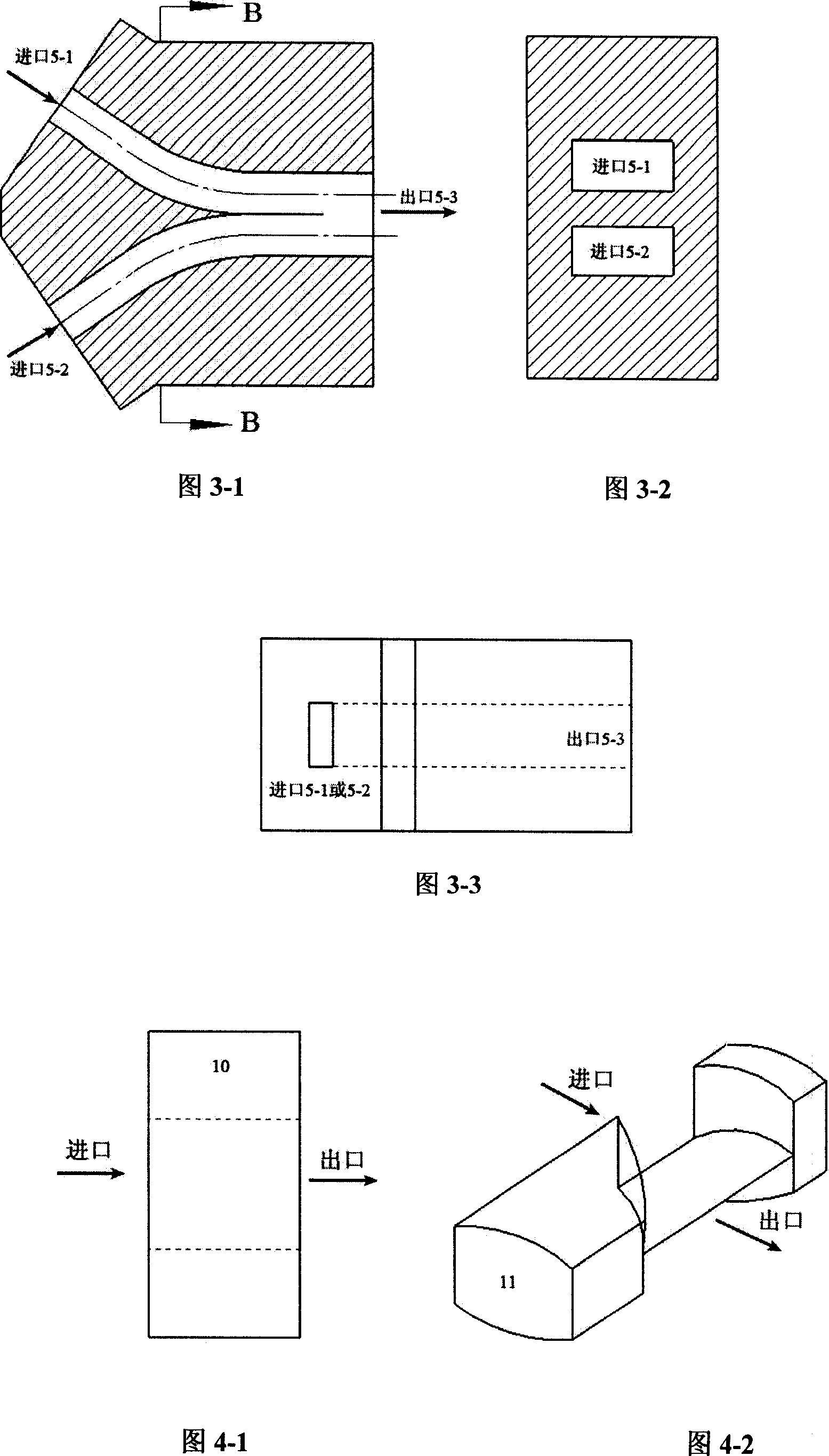

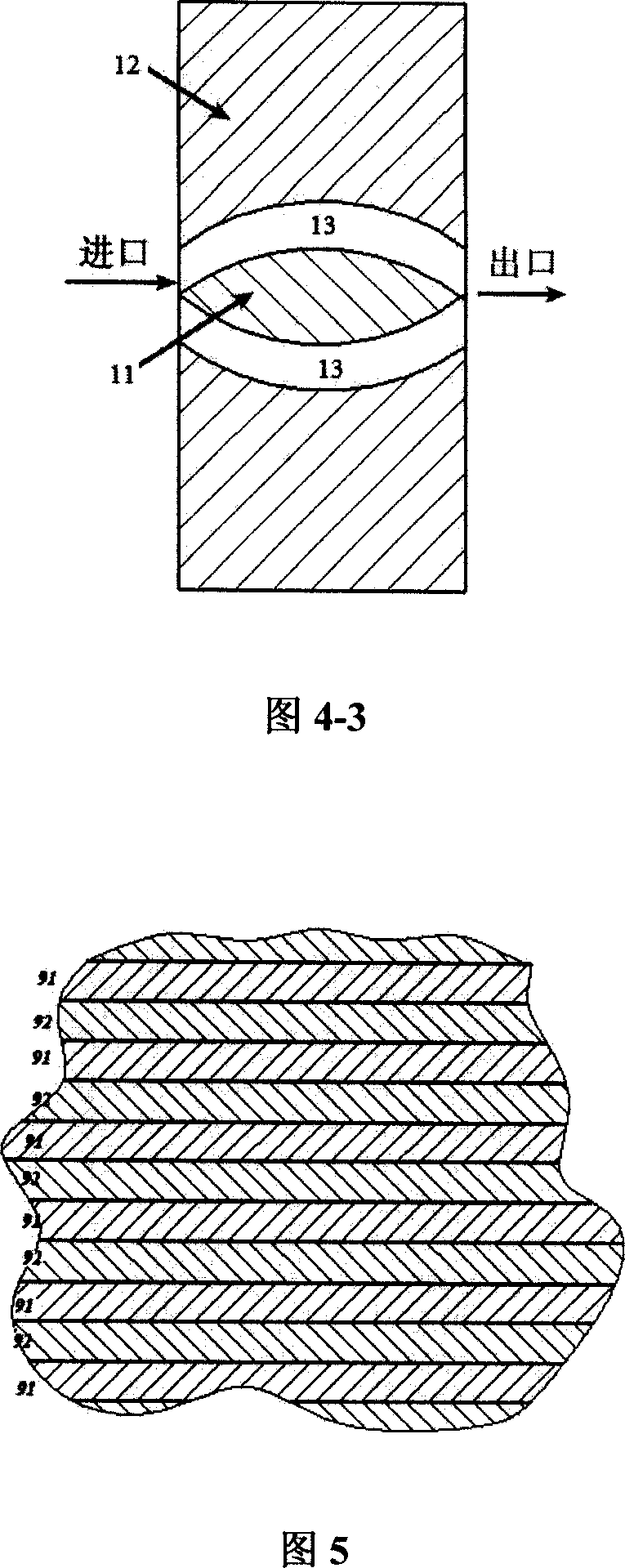

[0021] The extrusion die for preparing alternating multi-layer polymer composite materials disclosed in this embodiment has an overall structural appearance as shown in Figure 1, including two connectors 3 and 4 fixedly connected to the outlets of extruder extrusion 1 and 2, one A confluence 5 fixedly connected with the connector, and a splitter 6 fixedly connected with the confluence. The flow channel in the connector is gradually transitioned from the cylindrical flow channel of the inlet section to the rectangular flow channel of the outlet section. The structure of the confluence is shown in Figures 2-1, 2-2 and 2-3, and the two inlets 5-1 and 5-2 connected to the rectangular flow channel outlets of the two connectors 3 and 4 are misaligned left and right Setting, that is, the two inlets are neither aligned up and down nor aligned left and right, and the two rectangular runners gradually merge into a rectangular runner 5-3 connected with the splitter. The structure of the...

Embodiment 2

[0023] The extrusion die for preparing alternating multi-layer polymer composite materials disclosed in this example has the same overall structure as that of Example 1, except for the structure of the confluence and the arrangement of the splitter. The structure of the confluence of this embodiment is shown in Figure 3-1, Figure 3-2 and Figure 3-3, and the two inlets 5-1 connected to the outlets of the rectangular flow channels of the two connectors 3 and 4 , 5-2 are aligned left and right, the two rectangular runners gradually merge into a rectangular runner 5-3 connected with the splitter, and the surface of the rectangular runner is perpendicular to the ground. The splitter is arranged vertically to the ground, even if the alternate laminated surfaces of the prepared composite materials are vertical to the ground. This setting method is beneficial to the installation and setting of the extruder.

[0024] The process of preparing alternating multi-layer polymer composite m...

Embodiment 3

[0031] A 1024-layer alternate composite PS / PMMA sheet with uniform thickness was prepared. Assemble the splitter containing 9 stacking units at the outlet of the confluence, set the temperature of the extruder and the mold, and adjust the screw speed of the extruder to reach the same speed after reaching the temperature. After normal operation, it can be connected with the cooling device 7 and the traction device 8 to prepare a 1024-layer alternate composite PS / PMMA sheet with uniform thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com