Development method of flexible pressure-sensitive element based on carbon nano-tube filled high polymer composite material

A carbon nanotube and composite material technology, applied in the field of sensors, can solve the problems of inability to meet stress measurement requirements, inability to measure the size of the contact force, difficult operation, etc., and achieve the effects of low cost, large range, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

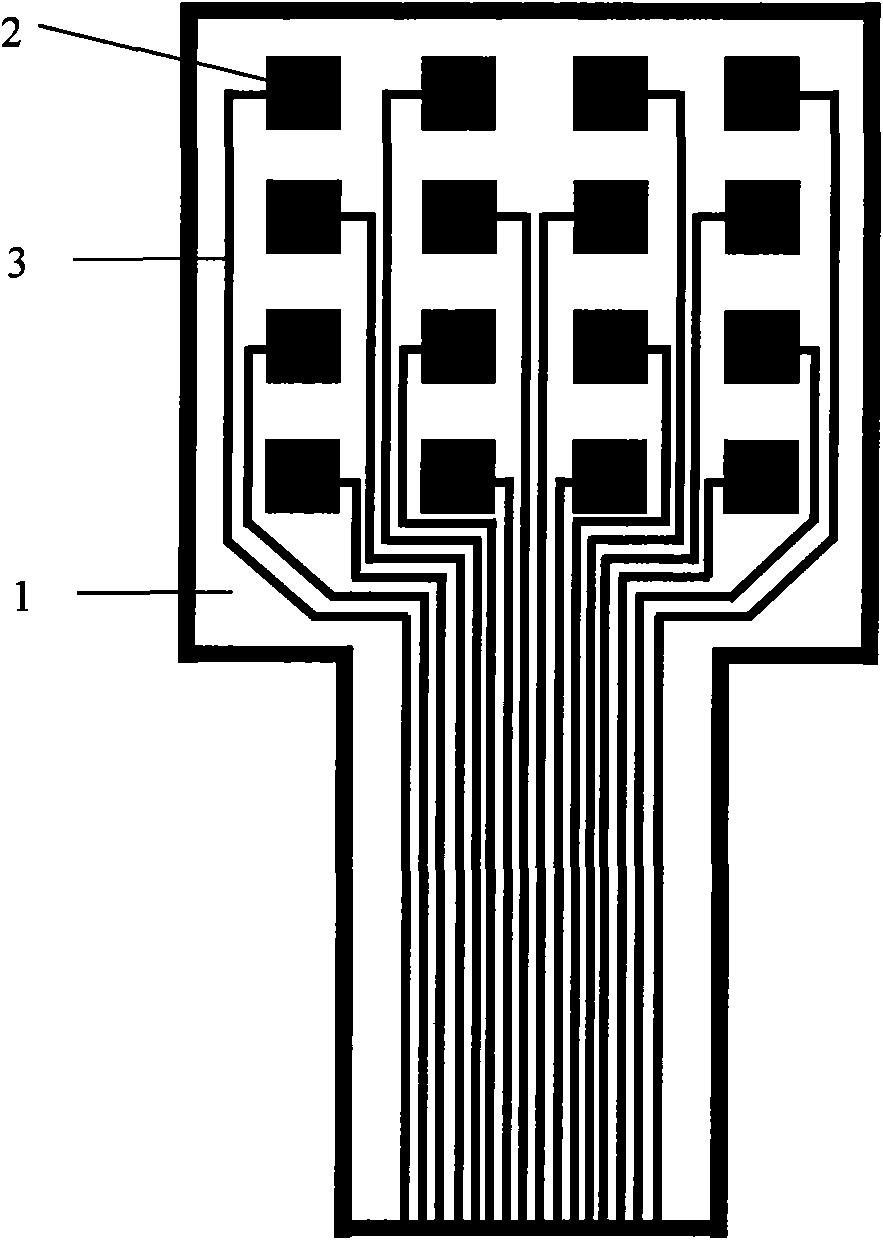

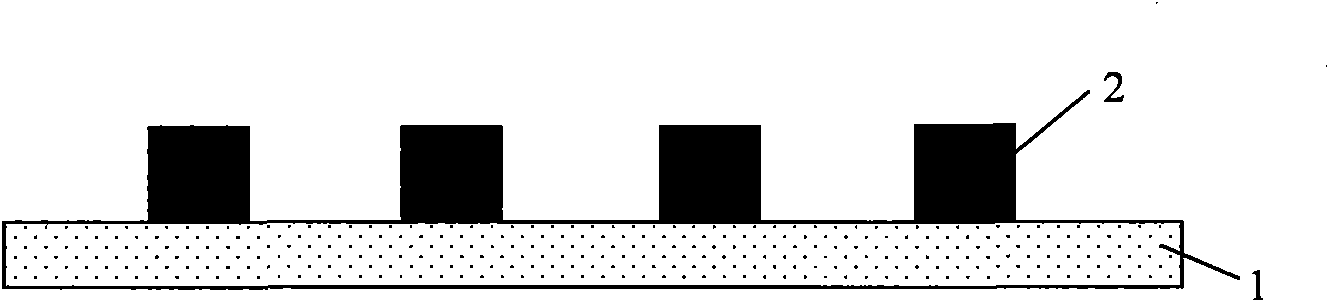

[0056] a. Lay a layer of copper foil electrodes and lead wires on a polyimide film with a thickness of 12.5 μm. The number of electrodes is 4×4=16, and the electrodes are completely separated;

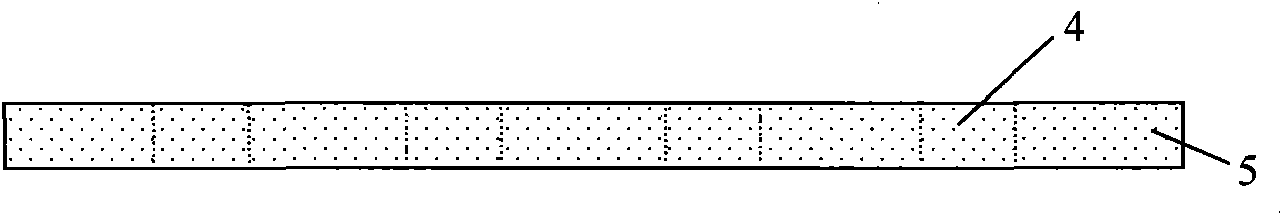

[0057] B, opening a window on another polyimide film, the shape, size, position and quantity of the window are consistent with the electrodes on the polyimide copper-clad film prepared in step a;

[0058] C, the part outside the electrode of the polyimide copper-clad film prepared in step a is coated with thermosetting adhesive;

[0059] d. Attach the polyimide film with windows prepared in step b to the polyimide film coated with thermosetting adhesive in step c. The position of the window is just enough to expose the copper foil electrode and the lead part It is packaged between two layers of polyimide film, and is packaged with flexible material packaging equipment for thermal compression packaging, so as to make a double-layer polyimide film with embedded electrodes and leads;

[...

Embodiment 2

[0069] a. Lay a layer of copper foil electrodes and lead wires on a polyimide film with a thickness of 12.5 μm. The number of electrodes is 4×4=16, and the electrodes are completely separated;

[0070] B, opening a window on another polyimide film, the shape, size, position and quantity of the window are consistent with the electrodes on the polyimide copper-clad film prepared in step a;

[0071] C, the part outside the electrode of the polyimide copper-clad film prepared in step a is coated with thermosetting adhesive;

[0072] d. Attach the polyimide film with windows prepared in step b to the polyimide film coated with thermosetting adhesive in step c. The position of the window is just enough to expose the copper foil electrode and the lead part It is packaged between two layers of polyimide film, and is packaged with flexible material packaging equipment for thermal compression packaging, so as to make a double-layer polyimide film with embedded electrodes and leads;

[...

Embodiment 3

[0082] a. Lay a layer of copper foil electrodes and lead wires on a polyimide film with a thickness of 12.5 μm. The number of electrodes is 4×4=16, and the electrodes are completely separated;

[0083] B, opening a window on another polyimide film, the shape, size, position and quantity of the window are consistent with the electrodes on the polyimide copper-clad film prepared in step a;

[0084] C, the part outside the electrode of the polyimide copper-clad film prepared in step a is coated with thermosetting adhesive;

[0085] d. Attach the polyimide film with windows prepared in step b to the polyimide film coated with thermosetting adhesive in step c. The position of the window is just enough to expose the copper foil electrode and the lead part It is packaged between two layers of polyimide film, and is packaged with flexible material packaging equipment for thermal compression packaging, so as to make a double-layer polyimide film with embedded electrodes and leads;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com