Natural liquid rubber slurry with added carbon nanotube and its prepn process

A technology of natural rubber and natural latex, which is applied in the field of natural rubber liquid slurry with carbon nanotubes added and its preparation, can solve the problems of not finding natural rubber liquid slurry, etc., and achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 2. Preparation of carbon nanotube suspension

[0032] Adding dispersant is an effective way to further improve the suspension effect of CNTs in natural rubber latex and promote the dispersion of CNTs. Sodium dodecylbenzenesulfonate (SDAS) is a commonly used anionic surfactant. Too much dispersant is unfavorable to the performance of powder rubber. When the mass ratio of dispersant to CNTs is 5% to 20%, the obtained The CNTs suspension has good stability.

[0033] 3. Adjust the pH value of carbon tube suspension

[0034] During the mixing process of CNTs-water suspension and natural latex, flocculation is easy to occur, and the main reason is that the ζ potential of latex decreases due to the addition of CNTs suspension. When the zeta potential drops to a certain critical value, the electrostatic repulsion between the latex particles is not enough to offset the attractive force between the particles, the balance between the latex particles is broken, and the latex part...

Embodiment 1

[0039] Place the CNTs at a volume ratio of V 硫酸 :V 硝酸 = In the mixed acid solution of 3:1, 1g of CNTs corresponds to 10ml of acid solution, boiled for 30min, washed and dried to obtain acid boiled CNTs. Take 30 g of acid boiled CNTs and 3 g of sodium dodecylbenzenesulfonate (SDAS), add them to deionized water with a mass ratio of CNTs of 10:1, and ultrasonically disperse to obtain a CNTs-water suspension. KOH was added to the suspension to bring the pH of the suspension to 10. Get solid content and be 60% natural rubber latex 100g, this suspension is joined in the natural rubber latex, add appropriate amount of deionized water to make its total solid content be 10%, and adopt magnetic stirrer through fully stirring more than 2 hours, make it Mix evenly to prepare a natural rubber liquid slurry with a CNTs content of 50 phr (that is, the mass ratio of CNTs to natural latex dry rubber is 50%).

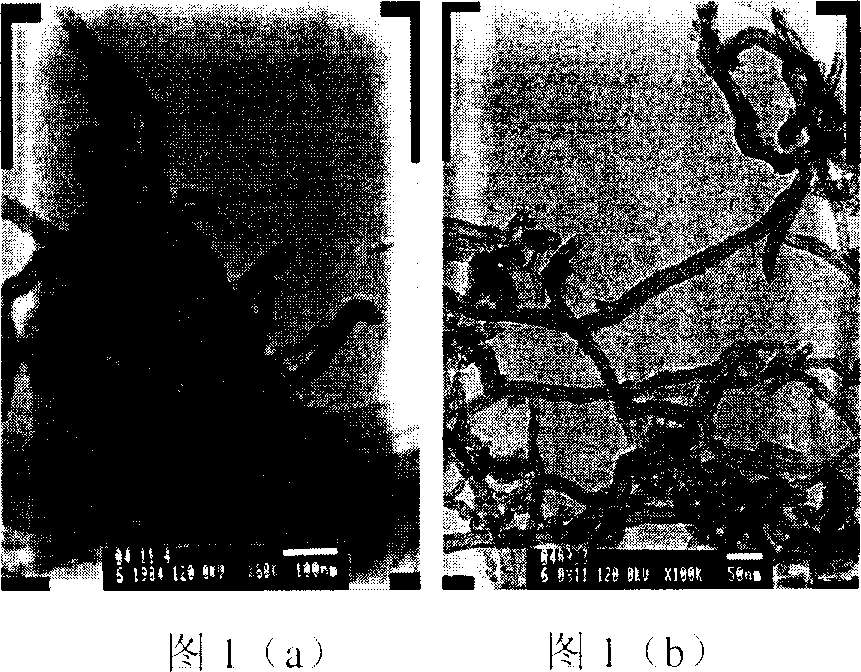

[0040] The CNTs and the CNTs that have not been acid-cooked are observed under a ...

Embodiment 2

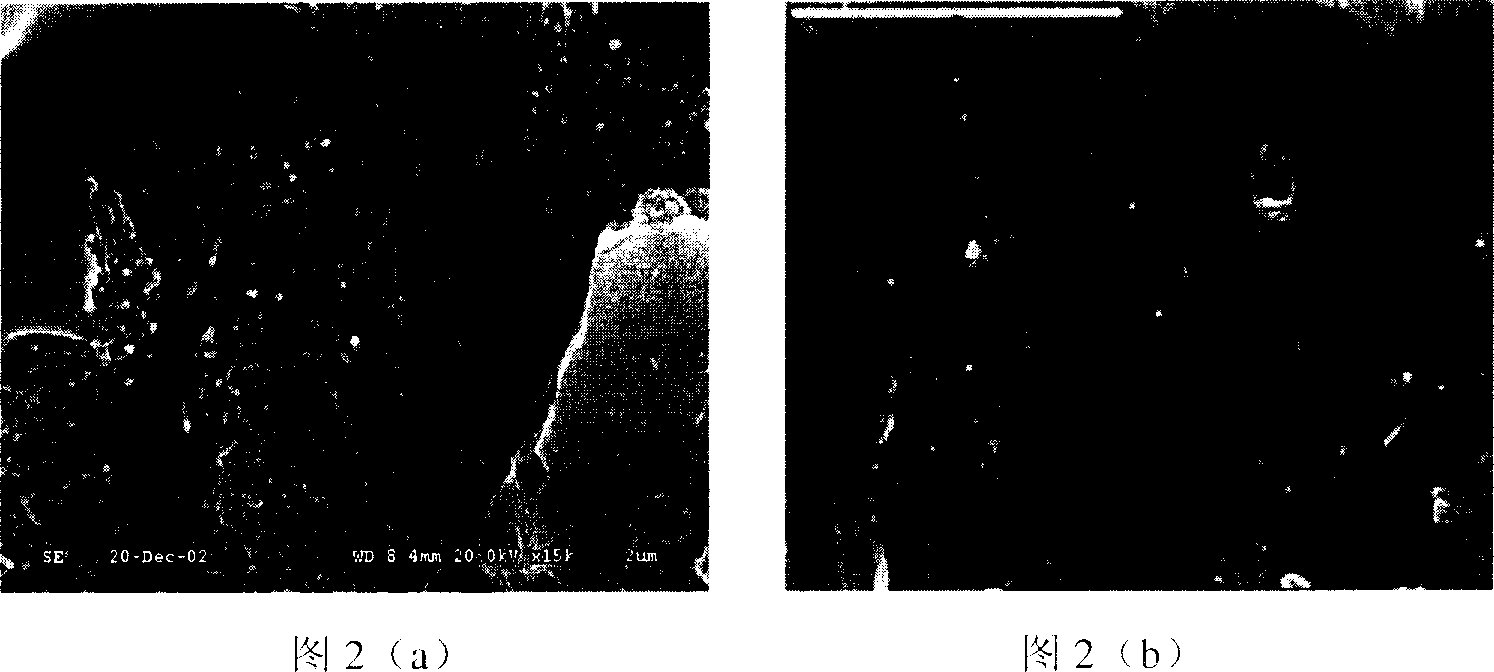

[0042]Take 3 g of acid-cooked CNTs and 0.3 g of sodium dodecylsulfonate, add them into deionized water with a mass ratio of CNTs of 10:1, and disperse by ultrasonic to obtain a CNTs-water suspension. Ammonia water was added to the suspension to bring the pH value of the suspension to 10.5. Get 25g of natural latex with a solid content of 60%, add this suspension to the natural latex, add an appropriate amount of deionized water to make the total solid content 10%, and use a magnetic stirrer to fully stir for more than 2 hours to make it Mix evenly to prepare a natural rubber latex suspension with a CNTs content of 20phr. The prepared powder rubber was observed by SEM, and the dispersion state of CNTs in it was good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com