Axial plunger type water hydraulic pump

A water-hydraulic, axial-column technology, applied in the direction of pumps, multi-cylinder pumps, liquid displacement machinery, etc., can solve the problems of design and manufacturing difficulties, low volumetric efficiency, large leakage, etc., to avoid sticking and jamming Dead, low noise, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

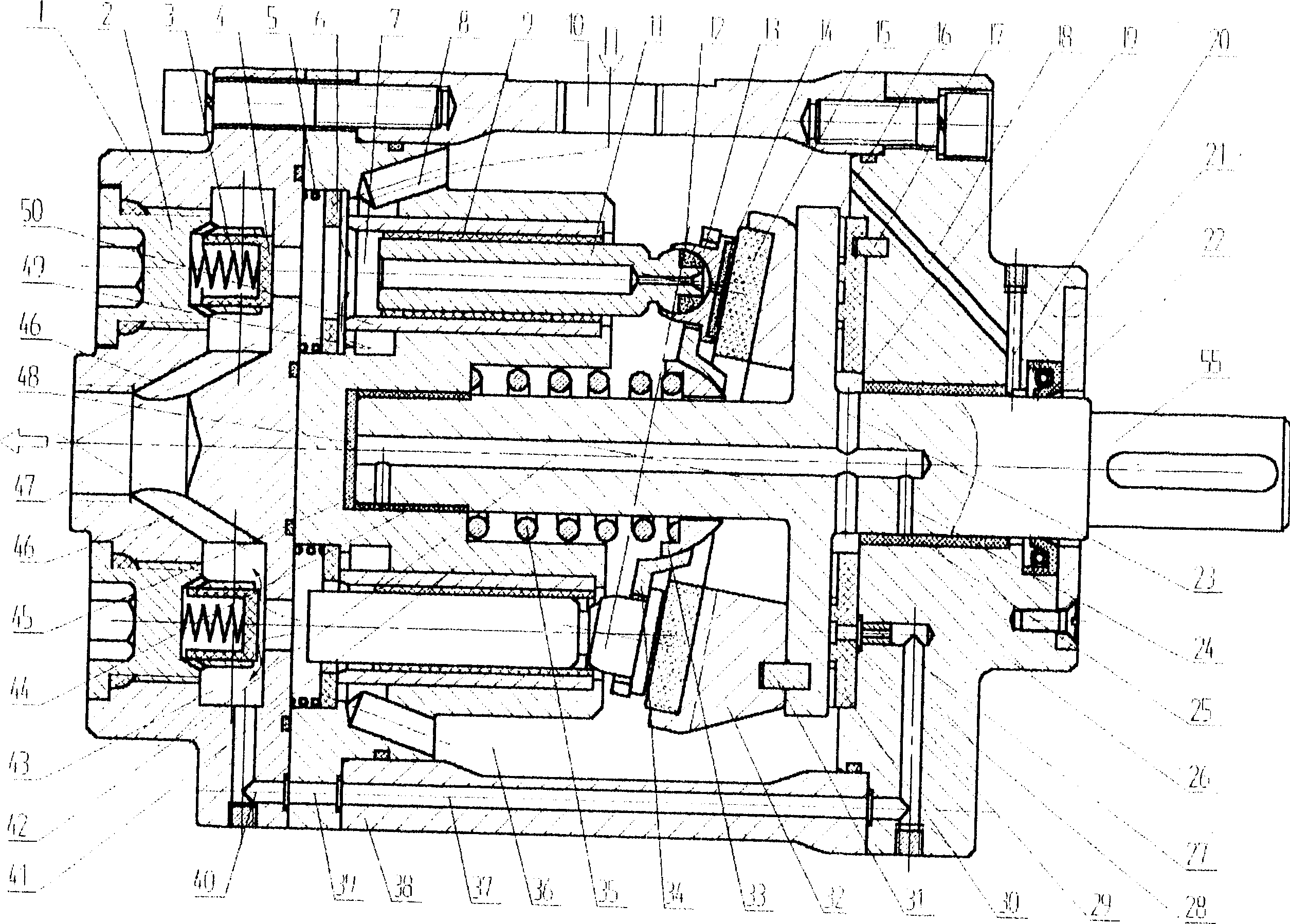

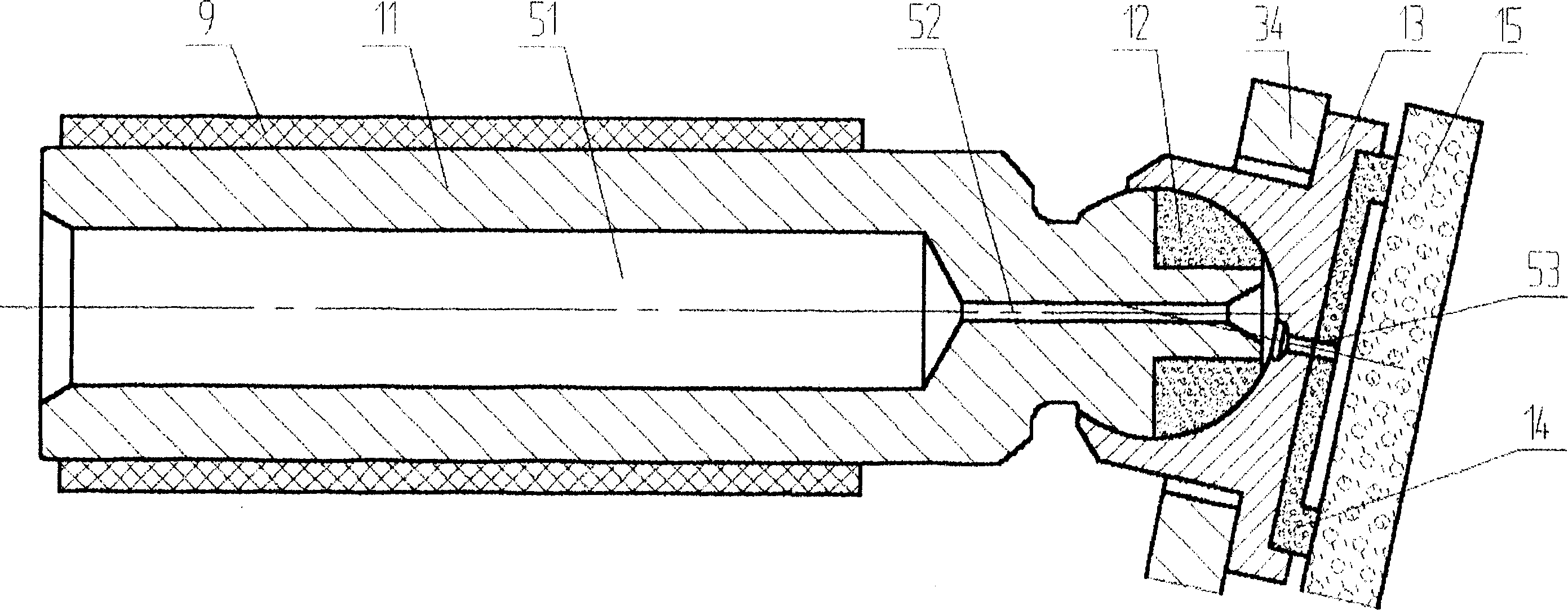

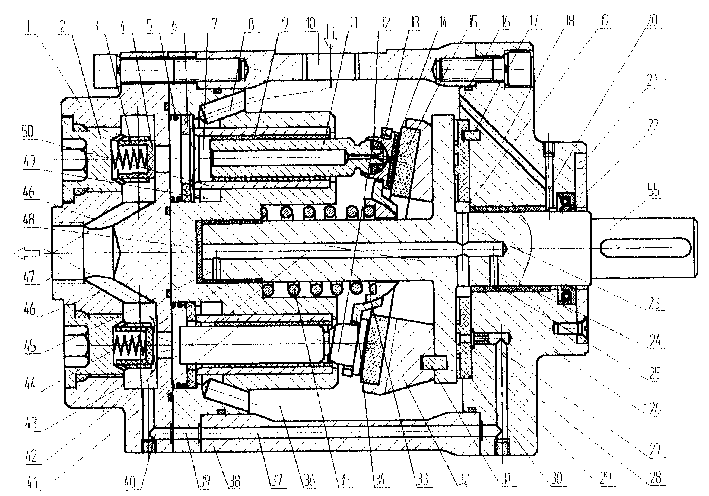

[0024] refer to Figure 1 ~ Figure 2 , the water hydraulic pump consists of a rear end cover 1, a discharge valve (composed of a discharge valve body 2, a discharge valve spring 3 and a discharge valve core 4), a suction valve (composed of a suction valve spring 5 and a suction valve core 6 ), cylinder block 41, pump housing 38, plunger shoe assembly (composed of plunger 11, hemispherical head 12, shoe 13 and shoe sole 14), friction plate 15, swash plate 32, center spring 35, ball hinge 33 , Return disc 34, thrust disc 16, main shaft 55, thrust bearing 30, front end cover 26, front sliding bearing 25, rear sliding bearing 44, shaft seal 22 and shaft seal cover 21 etc. constitute.

[0025] Several (such as 5, 7 or 9) plunger holes 7 parallel to the axis of the cylinder body (axial) are evenly distributed in the circumferential direction of the cylinder body 41, and the outer metal cylinder sleeve 50 and the inner plastic cylinder sleeve are embedded in the plunger holes. 9. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com