Self-repaired polyalcohol composite material at room temperature

A composite material and polymer technology, applied in the field of self-healing polymer composite materials, can solve the problems of insoluble polydimethylsiloxane, easy deactivation, inability to phase separation, etc., and achieve good bonding repair effect, It is not easy to penetrate and volatilize, and it is beneficial to the effect of mutual diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

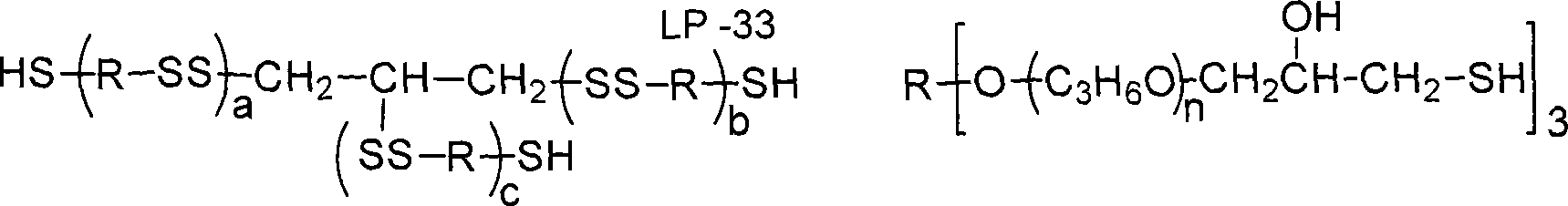

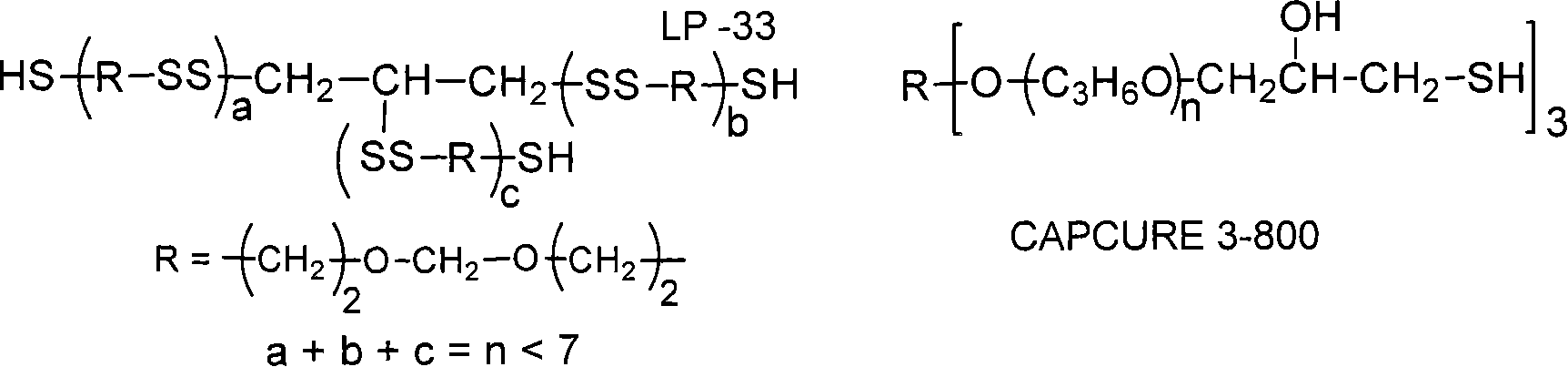

[0038] The preparation of the capsule that contains liquid epoxy resin: 12.5g melamine and 27.1g formaldehyde generate prepolymer under 70~75 ℃, pH value 9~10 conditions, cool down to 60 ℃, add 0.5ml50% (weight ratio) hydrochloric acid Aqueous solution and 28g methanol were stirred for 0.5 hour, and the solution changed from cloudy to clear. Add 200ml of water and 60g of diglycidyl tetrahydrophthalate, use a homogenizer 8×10 3 Rotate per minute to disperse for 5 minutes, drop 2 drops of tributyl phosphate to eliminate the bubbles in the emulsion. Adjust the pH of the system to 2.5-3.0, and react at 50-55°C for 1 hour. After cooling, filter, wash and dry in vacuum. Yield: 93.24%. The average size is 15.47 μm. Capsule core content: 86.13%.

Embodiment 2

[0040] Containing the preparation of the capsule of liquid polythiol: 50g pentaerythritol tetrakis (mercapto propionate) joins in 200ml and contains 2% (accounting for total weight ratio) in styrene sodium maleate aqueous solution, mixture is with emulsifying machine with 10 4 Disperse for 5 minutes at a speed of rpm, and drop 2 drops of tributyl phosphate to eliminate the bubbles in the emulsion. Pour the prepolymer produced by 12.5g melamine and 27.1g formaldehyde at 70-75°C and pH 9-10 into the above emulsion, adjust the pH of the system to 2.7-3.0, and react at 50°C for 1 hour. After cooling, filter, wash and dry in vacuum. Yield: 90.23%; average capsule diameter: 14.35 μm; capsule core content: 84.92%.

Embodiment 3

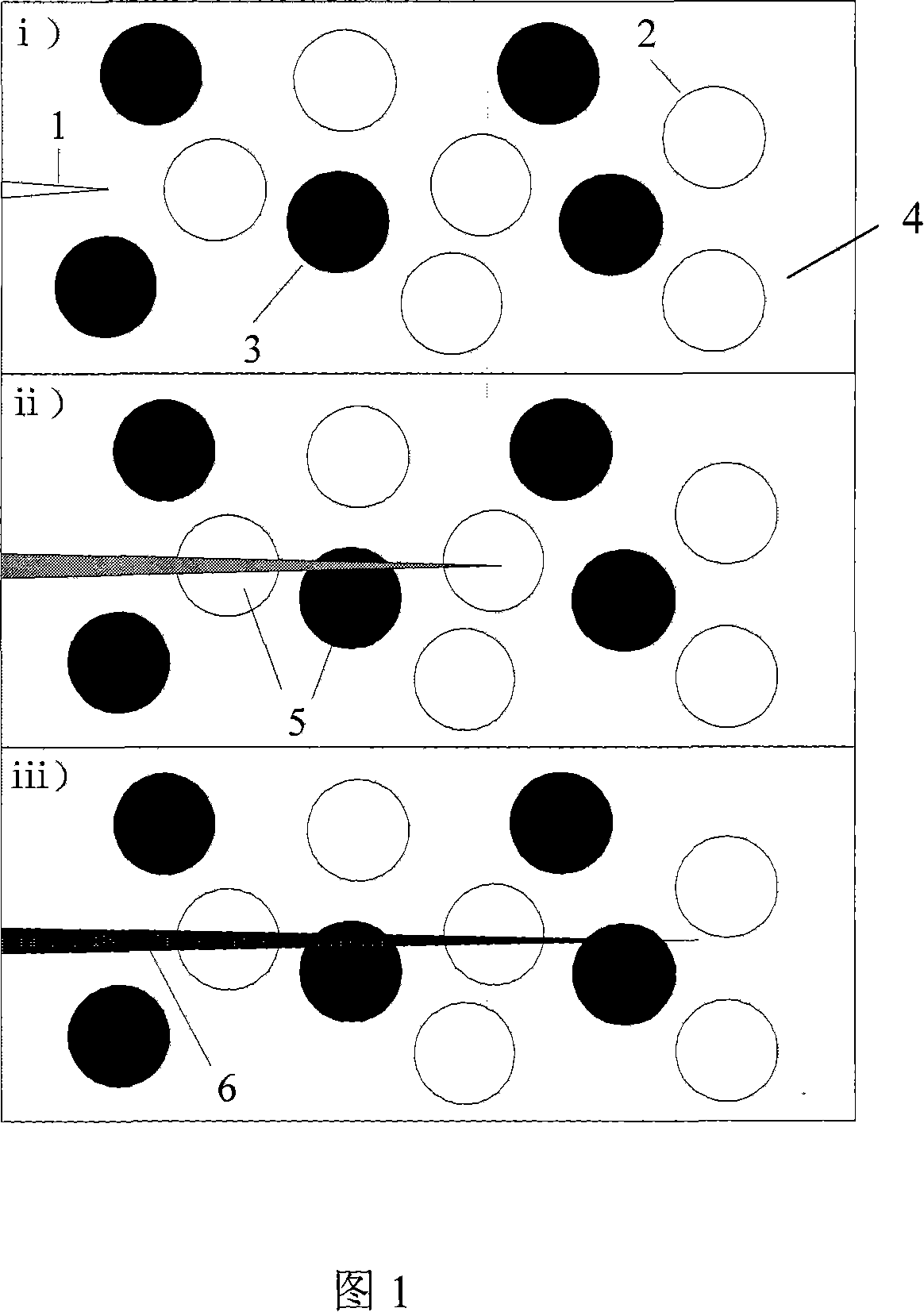

[0042] Take by weighing 10% by weight of epoxy resin capsules prepared by Example 1 and 10% by weight of mercaptan capsules prepared by Example 2, and evenly disperse them in 100 parts of EPON 828 epoxy resins at 40~50°C, add 12.5 Parts of diethylenetriamine were quickly mixed and degassed, poured into a silicone rubber mold and cured for 24 hours, and then cured at 40°C for 24 hours.

[0043] A tapered double cantilever beam (TDCB) specimen was used to conduct a fracture test and evaluate the repair efficiency of the material: a pre-crack was generated by tapping a thin blade into the molded incision of the sample, and a load was applied perpendicular to the pre-crack direction with a pin load fixture. The initial fracture toughness was determined from the critical load for crack propagation and specimen failure. After damage, remove the load and allow the crack to heal at room temperature (20-25°C). Fracture toughness was re-measured after 24 and 48 hours to quantify repair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com