Dopamine compound modified or coated nano particle modified polymer composite material and preparation method thereof

A nanoparticle and composite material technology, which is applied in the field of nanoparticle/polymer composite material preparation, can solve the problems of narrow range of modified objects, complex process, harsh reaction conditions, etc., and achieves easy-to-operate preparation methods, simple preparation methods, and comprehensive performance. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

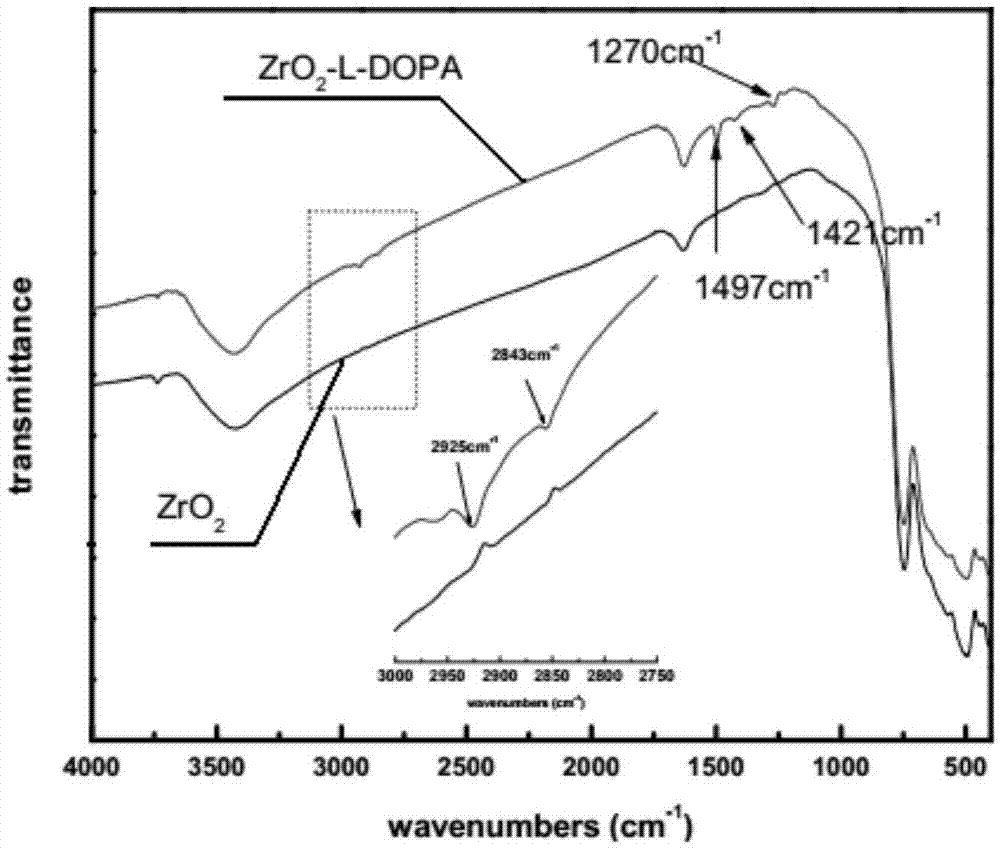

[0024] A dopamine compound modified or encapsulated nanoparticle modified polymer composite material is prepared by the following method: (1) 1 part (parts by mass) of ZrO 2 Nanoparticles are dispersed in the Tris-HCl buffer solution of pH=8.5 under the effect of ultrasonic / mechanical stirring (ultrasonic power is 2000W, ultrasonic frequency is 1MHz), then add 0.1 part of dopamine, at room temperature (25 ℃ ), ultrasonic / mechanical stirring (the power of ultrasonic is 2000W, the frequency of ultrasonic is 1MHz) to react for 24h, filter, wash, and dry to obtain the nano ZrO modified or encapsulated by dopamine 2 . (2) Dissolve 100 parts of epoxy resin in an organic solvent, add dopamine-modified or encapsulated nano-ZrO 2 , ultrasonic / stirring (ultrasonic power is 2000W, ultrasonic frequency is 1MHz) treatment for 0.5h, at 60°C, vacuum drying, removal of organic solvent, can be modified or encapsulated nano-ZrO 2 Modified epoxy resin compound.

[0025] In this example, the u...

Embodiment 2

[0027] A dopamine compound modified or encapsulated nanoparticle-modified polymer composite material is prepared by the following method: (1) 1 part of ZnO is stirred under ultrasonic / mechanical stirring (ultrasonic power is 2000W, ultrasonic frequency is 1MHz) Disperse in Tris-HCl buffer solution with pH = 8.5 under action, then add 10 parts of dopamine, at room temperature (25°C), ultrasonic / mechanical stirring (ultrasonic power is 2000W, ultrasonic frequency is 1MHz) and react for 12h , filtered, washed, and dried to obtain dopamine-modified or encapsulated nano-ZnO. (2) Dissolve 100 parts of epoxy resin in an organic solvent, add dopamine-modified or encapsulated nano-ZnO, and ultrasonically / stirrer (ultrasonic power is 2000W, ultrasonic frequency is 1MHz) for 0.5h, at 60°C Under vacuum drying, the organic solvent is removed, and the nano-ZnO modified epoxy resin composite material modified or wrapped by dopamine is obtained.

Embodiment 3

[0029] A dopamine compound modified or encapsulated nanoparticle-modified polymer composite material is prepared by the following method: (1) 1 part of SiO 2 Under the action of ultrasonic / mechanical stirring (the power of ultrasonic is 2000W, the frequency of ultrasonic is 1MHz), it is dispersed in the Tris-HCl buffer solution with pH=8.5, then add 10 parts of dopamine, at room temperature (25°C), Ultrasonic / mechanical stirring (ultrasonic power is 2000W, ultrasonic frequency is 1MHz) for 12h, filtered, washed and dried to obtain dopamine-modified or encapsulated nano-SiO 2 . (2) Dissolve 100 parts of epoxy resin in an organic solvent, add dopamine-modified or encapsulated nano-SiO 2 , ultrasonic / stirring (ultrasonic power is 2000W, ultrasonic frequency is 1MHz) treatment 0.5h, at 60 ℃ temperature, remove organic solvent, obtain dopamine-modified or encapsulated nano-SiO 2 Modified epoxy resin composites.

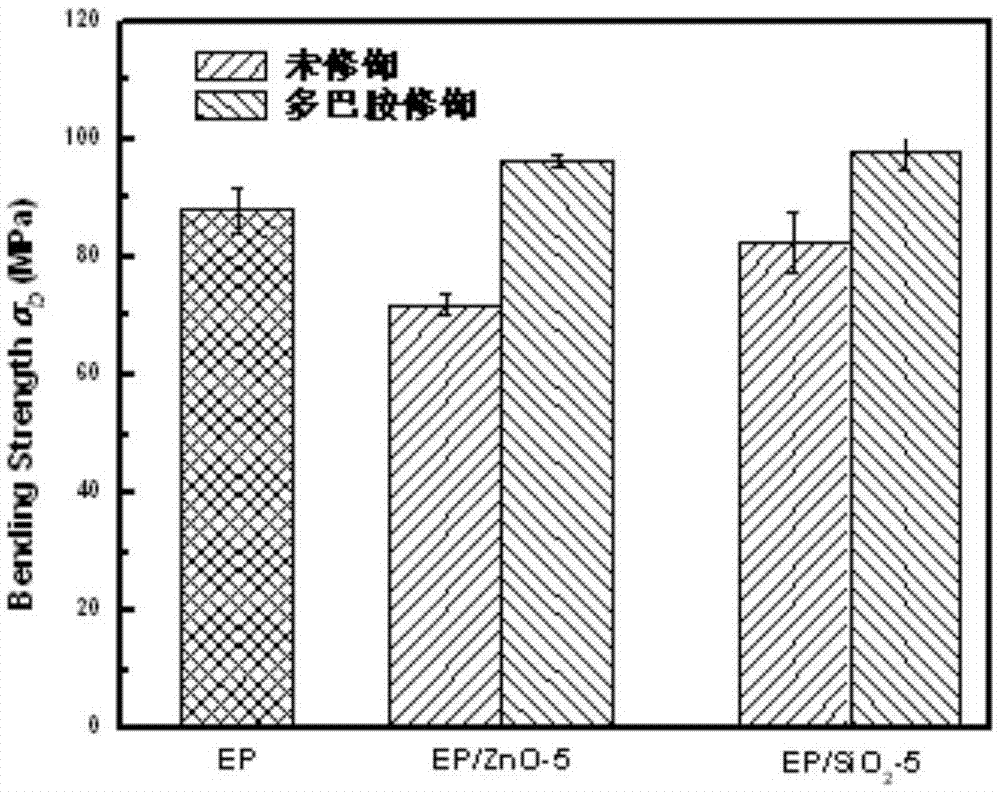

[0030] Epoxy resin, nano-ZnO modified epoxy resin composite, nano-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com