Graphene filled polymer matrix composite material and its preparation method

A technology for filling polymers and composite materials, applied in the field of graphene-filled polymer-based composite materials and their preparation, can solve the problems of complex preparation methods and difficult to scale, and achieves wide source of raw materials, suitable for large-scale production, and weather resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

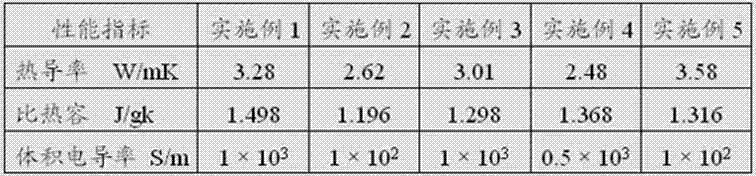

Examples

Embodiment 1

[0027] Take the raw material according to the following parts by weight:

[0028] PP (Shanghai Petrochemical, F800EPS) 99 parts,

[0029] Graphene microflakes (Xiamen Kaina, KNG150) 0.1 parts,

[0030] KH-550 0.01 parts,

[0031] 0.5 parts of stearic acid,

[0032] Polyethylene wax 9.5 parts,

[0033] Among them, the thickness of the graphene microsheet is 15nm, which is composed of 10 layers of single-layer graphene;

[0034] (1) Dissolve the graphene microchips in the ethanol solution with the coupling agent first, so that the ethanol solution dissolved in the coupling agent is completely immersed in the graphene microchips, stir at high speed with a stirrer, and place it in the ultrasonic pool at the same time Ultrasonic dispersion for 30 minutes, and then placed in a blast oven at 105 ° C for 16 hours;

[0035] (2) Accurately weigh the graphene microflakes, PP resin, stearic acid and polyethylene wax processed in step (1), add them into a high-speed mixer and mix them...

Embodiment 2

[0039] Take the raw material according to the following parts by weight:

[0040] PBT (Rand Nano, 130GRS) 95 parts,

[0041] Graphene microflakes (Xiamen Kaina, KNG150) 5 parts,

[0042] 0.5 parts of NDZ-101,

[0043] 1.5 parts of stearic acid,

[0044] Polyethylene wax 1 part,

[0045] Among them, the thickness of the graphene microsheet is 12nm, which is composed of 20 layers of single-layer graphene;

[0046] (1) Dissolve the graphene microchips in the ethanol solution with the coupling agent first, so that the ethanol solution dissolved in the coupling agent is completely immersed in the graphene microchips, stir at high speed with a stirrer, and place it in the ultrasonic pool at the same time Ultrasonic dispersion for 30 minutes, and then dried in a blast oven at 120°C for 8 hours;

[0047] (2) Accurately weigh the graphene microflakes, PBT resin powder, stearic acid and polyethylene wax processed in step (1) and add them into a high-mixer to mix evenly. The mixing ...

Embodiment 3

[0051] Take the raw material according to the following parts by weight:

[0052] PVC (Guizhou Anlong, SG-5) 90 parts,

[0053] Graphene microflakes (Xiamen Kaina, KNG150) 0.1 parts,

[0054] A-171 1 copy,

[0055] Zinc stearate 1.5 parts,

[0056] 5 parts of methyl silicone oil,

[0057] Among them, the thickness of the graphene microsheet is 15nm, which is composed of 10 layers of single-layer graphene;

[0058] (1) Dissolve the graphene microchips in the ethanol solution with the coupling agent first, so that the ethanol solution dissolved in the coupling agent is completely immersed in the graphene microchips, stir at high speed with a stirrer, and place it in the ultrasonic pool at the same time Ultrasonic dispersion for 30 minutes, and then dried in a blast oven at 90°C for 24 hours;

[0059] (2) Accurately weigh the graphene microflakes, PVC resin, zinc stearate and methyl silicone oil processed in step (1) and add them into a high-mixer to mix evenly. The mixing tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com