Polymer electrolyte fuel cell

A polymer electrolyte and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of reduced basic performance of batteries, easy reduction of conductivity of gas diffusion electrodes, uneven diffusion, etc. , to achieve the effect of improving output performance and long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach I

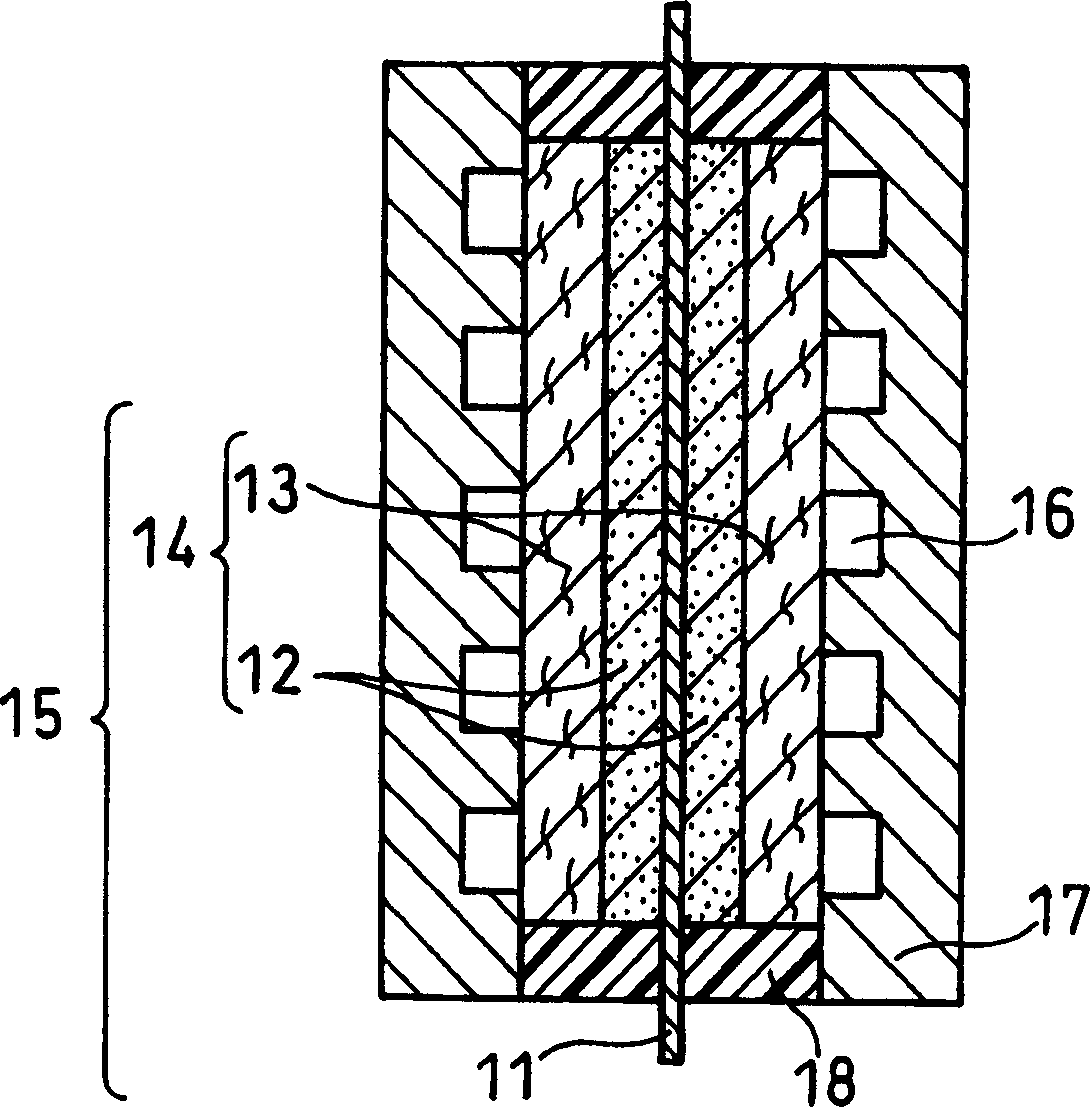

[0066] [Embodiment [I]: Drainage of Gas Diffusion Layer in Thickness Direction]

[0067] According to the first form in the embodiment [I] of the present invention, the gas diffusion layer constituting the polymer electrolyte fuel cell is provided with a porous carbon support, and the pores are distributed in a direction in which the catalyst layer becomes thinner and the separator side becomes thicker. tilt. That is, the gas diffusion layer has a different pore distribution in the thickness direction. By forming such an inclination, both the discharge of water and the water retention of the catalyst layer can be achieved.

[0068] That is, the moisture in the catalyst layer is held in the catalyst layer by the gas diffusion layer with fine pore distribution. However, if excess moisture is generated, the moisture overflows from the catalyst layer and reaches the gas diffusion layer, and the moisture is introduced into the gas diffusion layer with coarser pore distribution. T...

Embodiment approach I

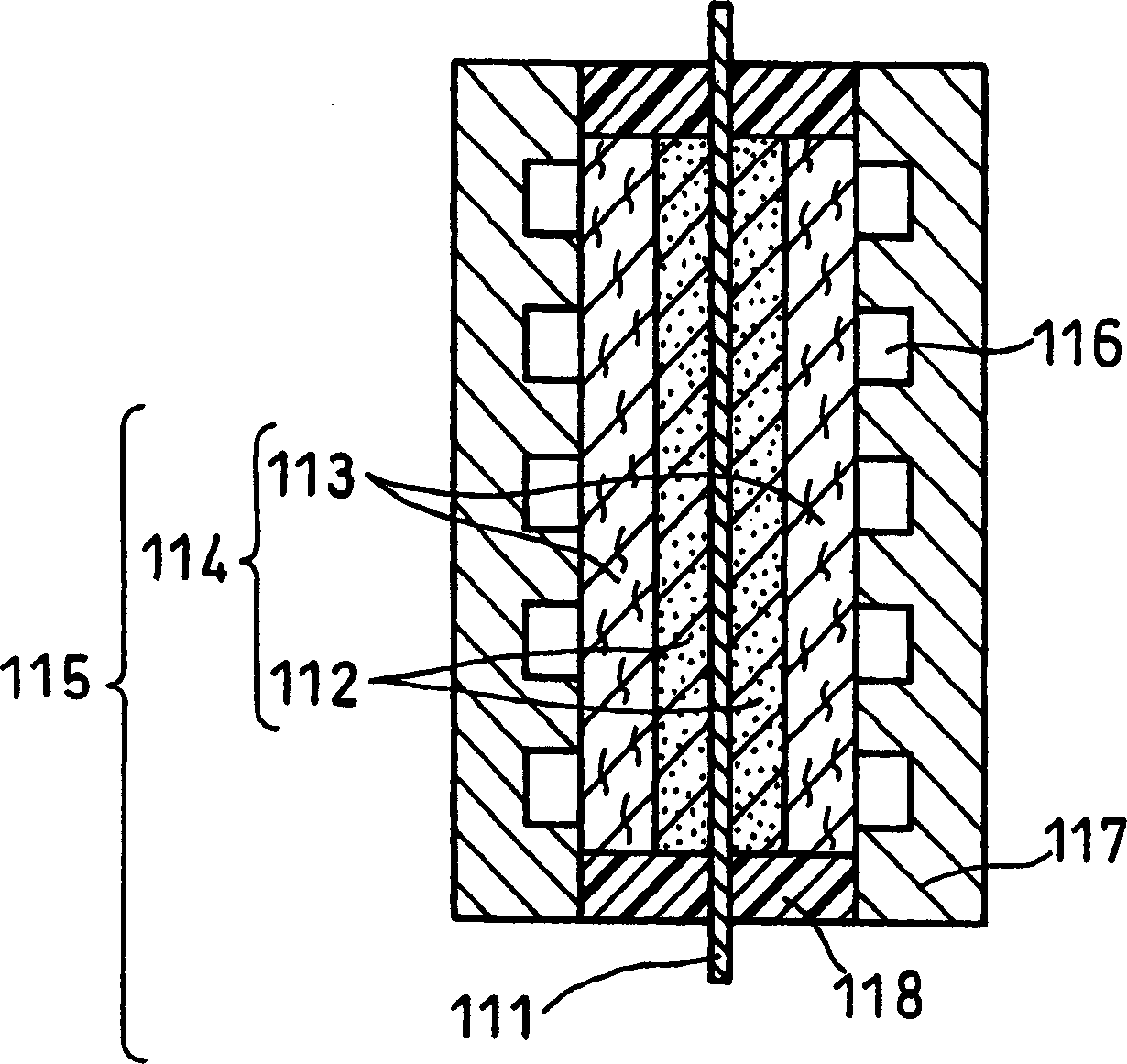

[0069] A carbon fabric based on a porous carbon support as a constituent element of a gas diffusion layer of a polymer electrolyte fuel cell according to the second aspect of the embodiment [I] of the present invention, in which pores of different sizes are distributed in the plane direction . That is, the pore distribution differs in the plane direction of the carbon fabric. That is, by arranging large pores and small pores, both the drainage of the gas diffusion layer and the gas diffusivity to the catalyst layer can be achieved.

[0070] That is, excess moisture generated from the catalyst layer is introduced into the large pores and quickly discharged from the catalyst layer. At this time, the gas diffuses through the small pores, so that the water discharge channel and the gas channel are separated, so that both the water discharge and the gas diffusibility to the catalyst can be achieved.

[0071] Based on the first and second aspects of the embodiment [I] of the prese...

Embodiment I-1

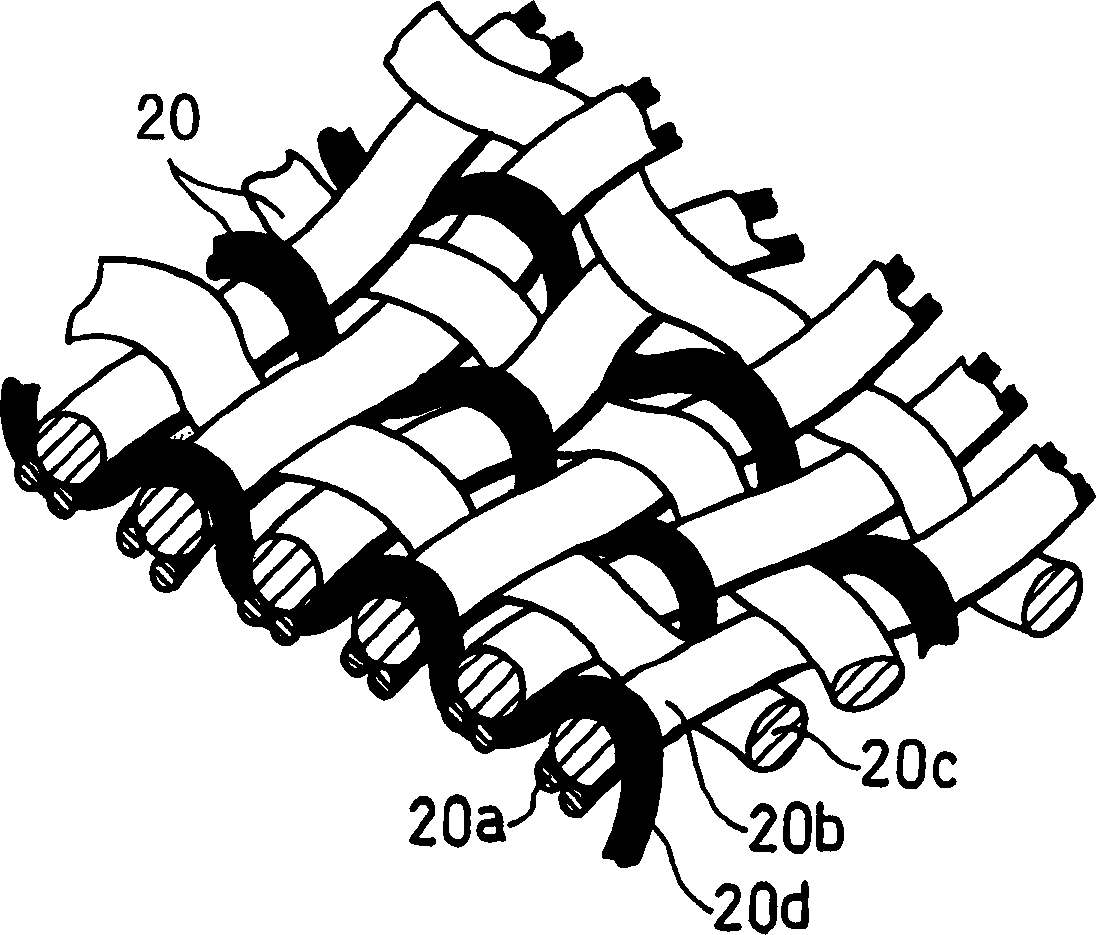

[0085] First, if figure 2 Schematically, the mesh thickness of the carbon fabric 20 is made so that it is thinner on the side of the catalyst layer and thicker on the side of the separator.

[0086] A wire with a thickness of about 300 microns made by twisting PAN-based fibers with a thickness of about 10 microns is used as the first layer of horizontal yarn 20a, and a wire with a thickness of about 600 microns made by twisting PAN-based fibers with a thickness of about 10 microns is used as the second layer. Two layers of weft yarns 20b are produced by weaving yarns with a thickness of about 600 microns as the second layer of warp yarns 20c and yarns with a thickness of about 300 microns as warp yarns 20d connecting the first and second layers.

[0087] This cloth was heated at 2000° C. for 24 hours in a nitrogen atmosphere to prepare a graphitized carbon cloth. figure 2 A schematic view showing a cross section of the carbon fabric 20 and a surface viewed from the second lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com