Surface Engineering of Thermoplastic Materials and Tooling

a thermoplastic material and tooling technology, applied in the direction of manufacturing tools, non-metal conductors, conductors, etc., can solve the problems of thermoset composite materials, limited overall production rate of structural components, and difficult imprinting of thermoplastic resin compositions into fiber reinforcing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Solvent Based PEI Polymer Sprayed Solution Applied to Tool

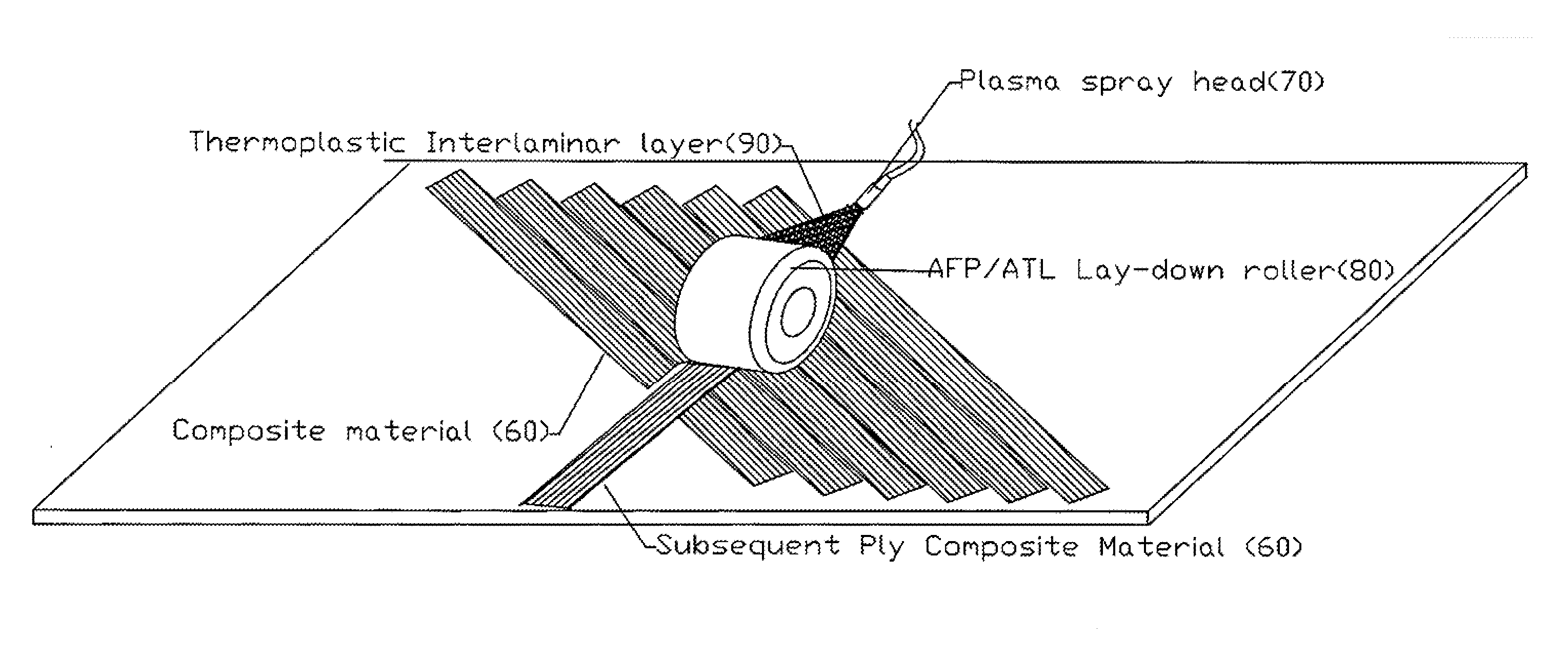

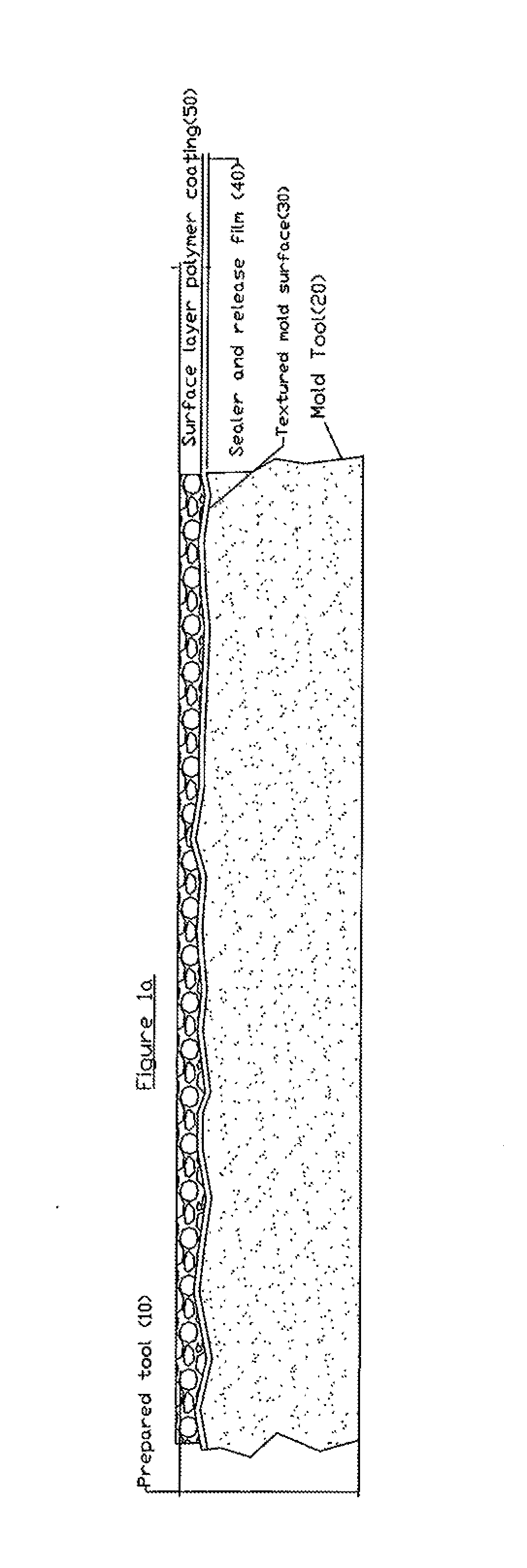

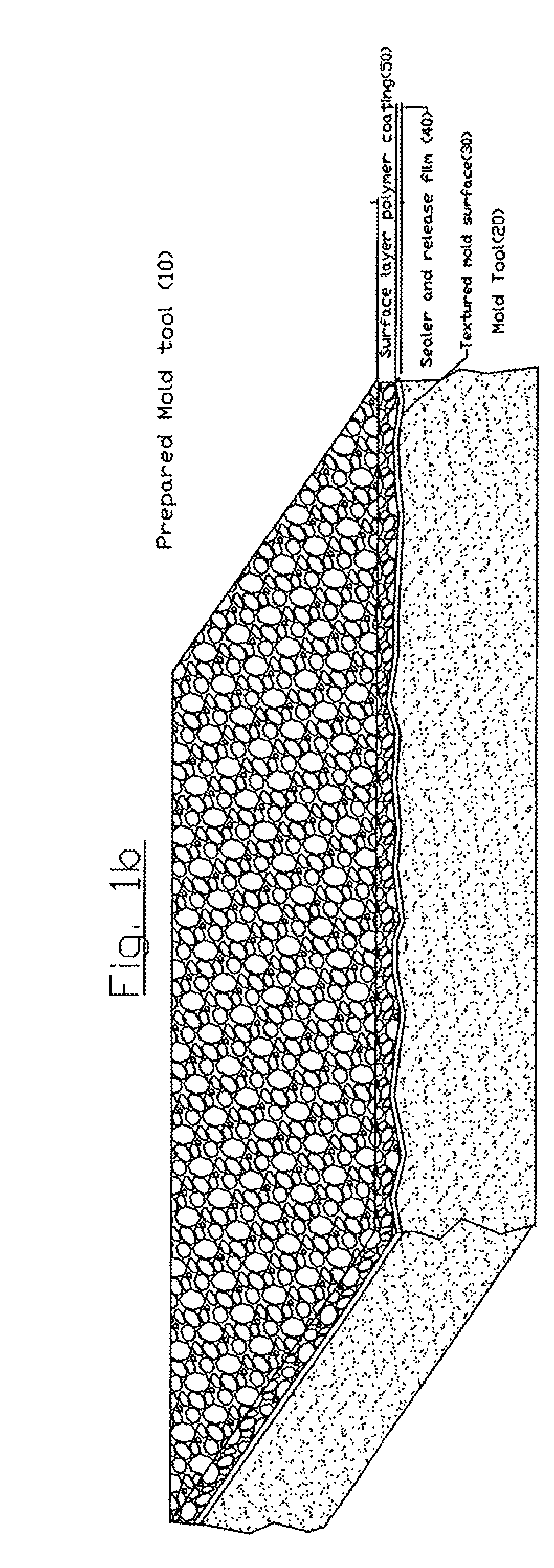

[0095]A formulation of PEI polymer, GE Ultem 1000P at 10% plus Dioxilane at 90% was plasma sprayed onto the mold surface of a steel mold tool which had a release film using an HVLP applicator.

[0096]To test the transfer of the PEI / Dioxilane first ply lay-down fiber reinforced thermoplastic composite, an 8 ply quasi-isotropic panel was created using APC PEKK / AS-4 uni-tape material. The panel was processed with a caul plate at an autoclave temperature of 720° F. (382° C.) and 100 psi of N2. The panel showed some surface anomalies on the coated face.

example 2

Water Based Slurry Hand Applied to Tool

[0097]A direct hand application technique was attempted using a mixture that included surfactant, water, hydrosize (sizing) and thermoplastic, as follows: 1) Sizing 90% / PEKK 10%. 2) D.I water 80% / Surfactant 10% / PEI-Diox. Premix solution 10%. 3) D.I water 80% / Surfactant 10% / PEKK 10%. 4) Sizing 80% / PEI powder 10% / Surfactant 10%). The resulting water based slurry thermoplastic surface layer polymer coating shrank rapidly on the mold surface of the mold tool and did not achieve adequate bonding onto metal mold tool. The surface layer polymer coating flaked off very easily with minimum abrasion.

example 3

PEK Polymer Plasma Sprayed onto Mold Tool

[0098]To impart a coating directly onto the mold surface of a mold tool applied with a sealer and release film, a plasma spray coating was performed using a Praxair SG 100 plasma gun and introduced PEK polymer into the jet stream to heat and accelerate the material to high velocity. Initially there was difficulty maintaining adhesion between the sealed / released tool and the PEK polymer, when the tool was allowed to cool to room temperature, likely caused by the difference in CTE (coefficient of thermal expansion) of the mold tool and the thermoplastic surface layer polymer coating on the smooth mold surface of the mold tool. It appeared that the skin coating released from the tool (Hysol® Frekote® GP sealer agent and release agent Frekote® 800).

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter D90 size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com