High temperature proton exchange membrane for fuel cell, and preparation method thereof

A technology of proton exchange membrane and fuel cell, which is applied in fuel cell parts, fuel cells, battery pack parts, etc., and can solve problems such as affecting the commercialization process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

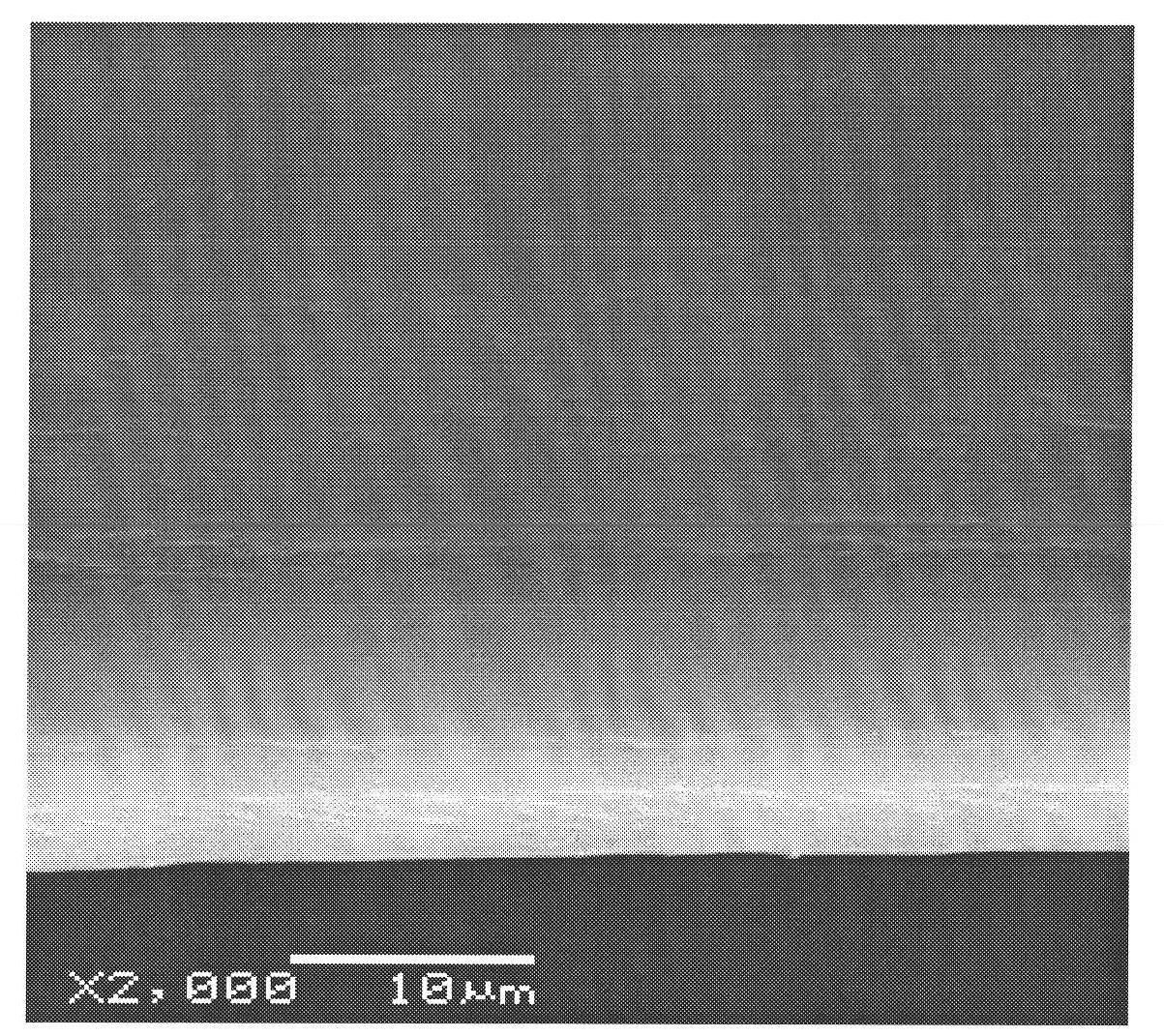

[0017] The method for preparing a high-temperature proton exchange membrane according to an embodiment of the present invention includes two steps of preparation of a homogeneous blend membrane and post-protonation treatment.

[0018] According to an embodiment of the present invention, the preparation of the high temperature resistant homogeneous blend membrane includes:

[0019] Dissolve the engineering plastic-like skeleton polymer with excellent chemical corrosion resistance and thermal stability in a suitable solvent (such as DMF, DMAC, NMP, DMSO) to obtain a transparent polymer solution, the concentration of which is usually 1 to 15 wt%. The best concentration is 3-10%, and the best concentration range is 4-8%.

[0020] Dissolve the hydrophilic polymer with N-heterocycle in the side chain, which has chemical corrosion resistance and thermal stability, in the same solvent as the previous polymer to obtain a transparent polymer solution, and its concentration is usually 1 ...

Embodiment 1

[0039] Weigh 1 weight unit of polyphenylsulfone (PPSF), dissolve it in 9 weight units of N,N-dimethylformamide (DMF), and stir until completely dissolved;

[0040] Weigh 1 weight unit of polyvinylpyrrolidone (PVP), dissolve it in 9 weight units of N,N-dimethylformamide (DMF), and stir until completely dissolved;

[0041] Mix the above two polymer solutions together and stir evenly, degas the polymer solution and cast it on a clean and flat solid surface (such as a glass plate) and dry the volatile solvent at 50°C to form a film.

[0042] After stripping, soak the obtained homogeneous blended membrane in concentrated phosphoric acid with a mass ratio of 60wt% for 36 hours, take out and dry the floating acid on the surface, and obtain a high-performance high-temperature proton exchange membrane.

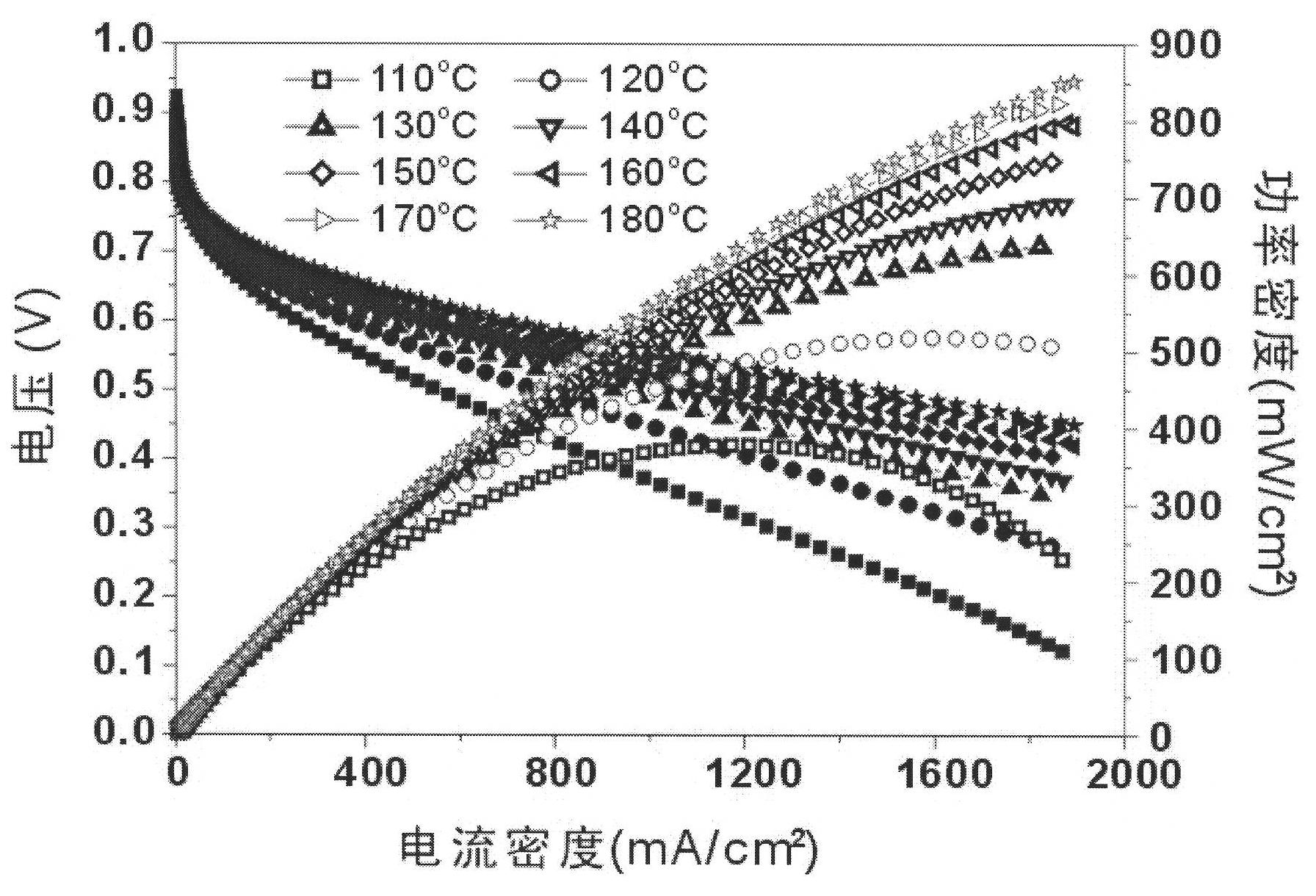

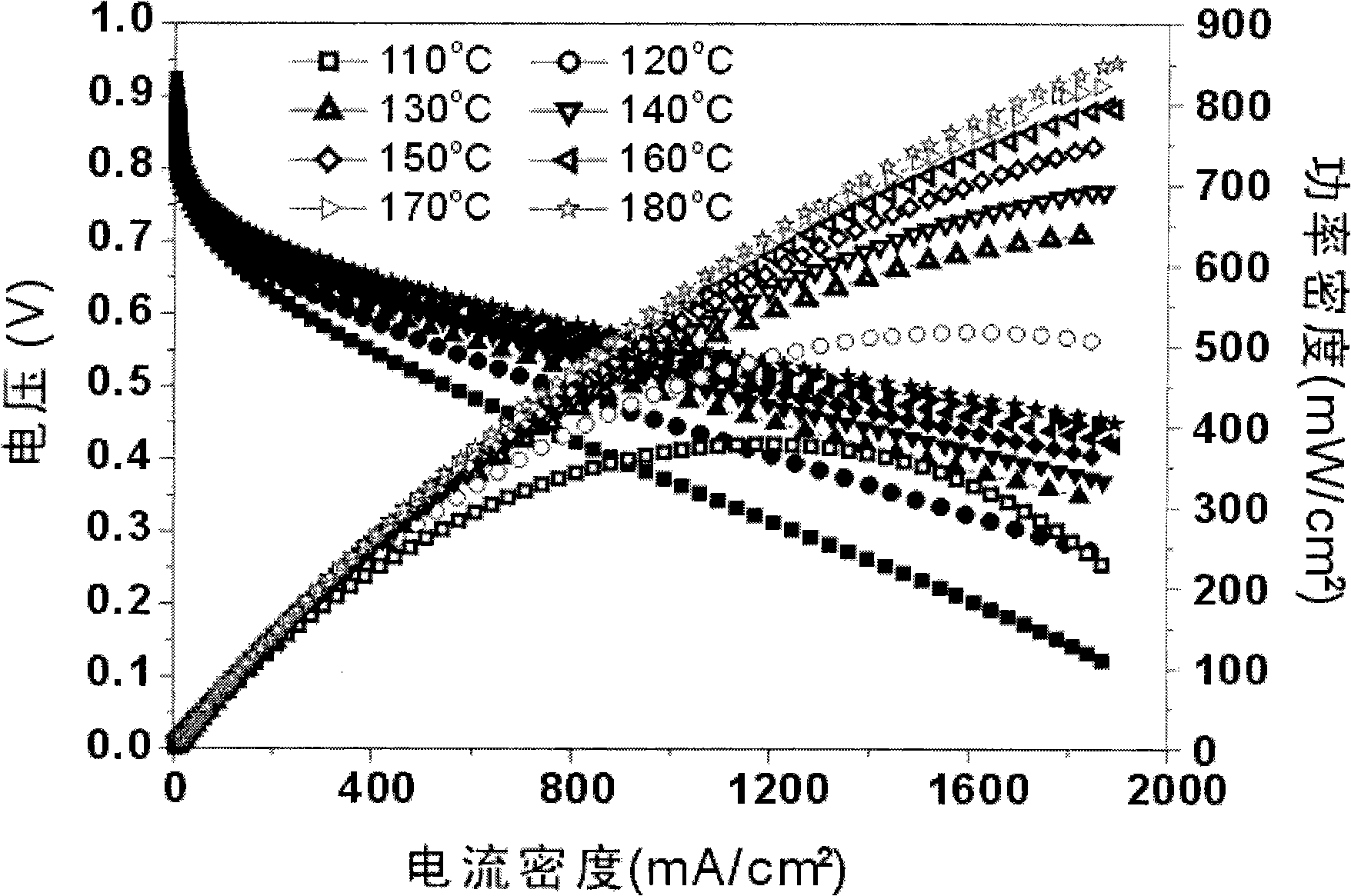

[0043] The resulting high temperature proton exchange membrane has high mechanical properties and good flexibility. The mechanical performance test adopts the national standard GB1302...

Embodiment 2

[0046] Weigh 1 weight unit of polysulfone (PSF), dissolve it in 10 weight units of N,N-dimethylacetamide (DMAc), and stir until completely dissolved;

[0047] Weigh 1.5 weight units of polyvinylpyrrolidone (PVP) and dissolve it in 10 weight units of N,N-dimethylformamide (DMAc), and stir until completely dissolved;

[0048] The above two polymer solutions are mixed together and stirred evenly,

[0049] After the polymer solution was degassed, the volatile solvent was dried at 60°C by casting method to form a film.

[0050] After demoulding, soak the obtained homogeneous blended membrane in concentrated phosphoric acid with a mass ratio of 70wt% for 24 hours, take out and dry the floating acid on the surface, and obtain a high-performance high-temperature proton exchange membrane.

[0051] The resulting high temperature proton exchange membrane has high mechanical properties and good flexibility. The mechanical property test adopts the national standard GB13022-91 for measure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com