Bio-based unsaturated polyester cured product and preparation method thereof

An unsaturated, bio-based technology, applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of molecular chain flexibility and high-performance polymer materials, and achieve easy reaction conditions and overcome flexibility Effects that are too large and source renewable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

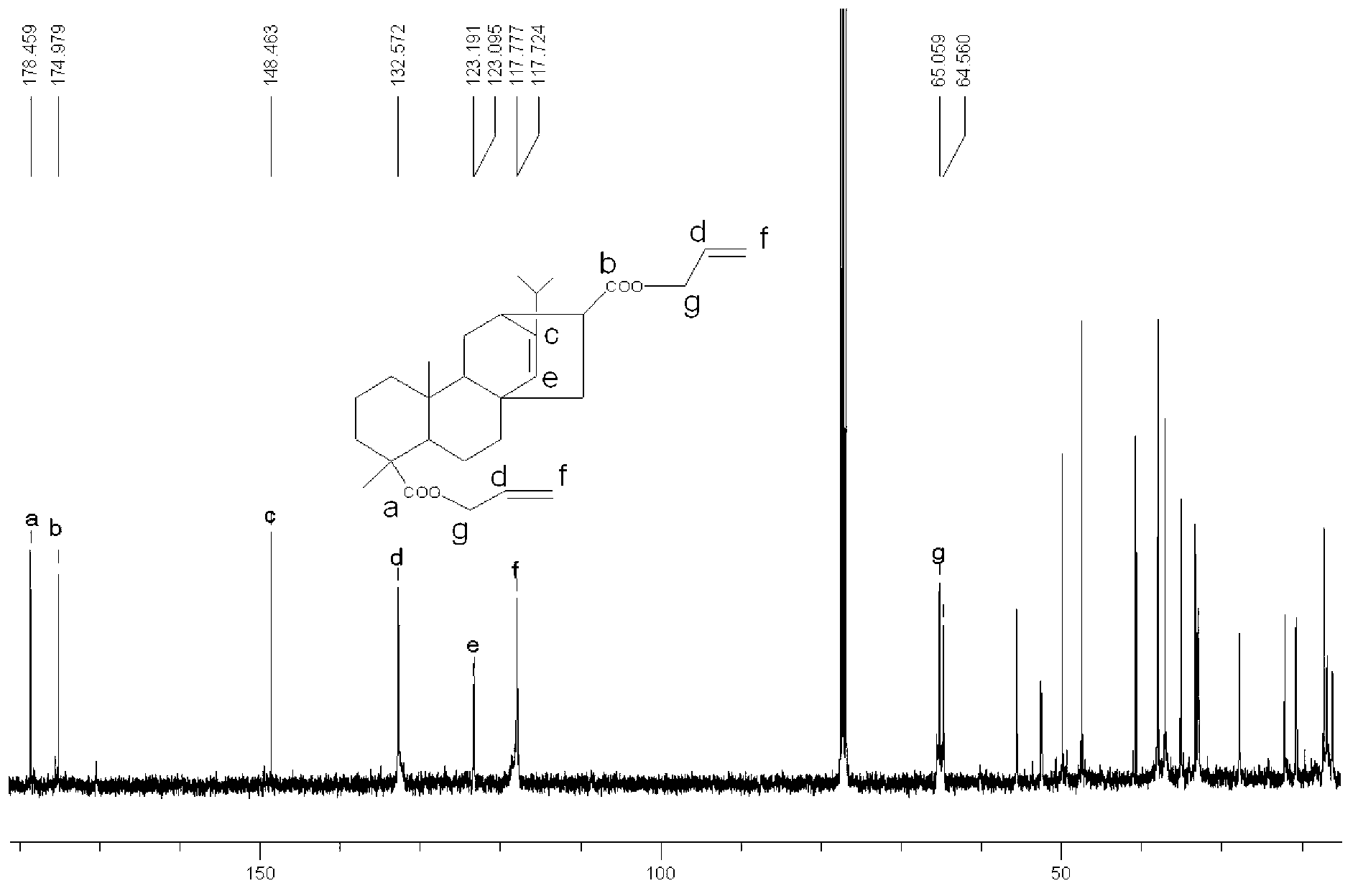

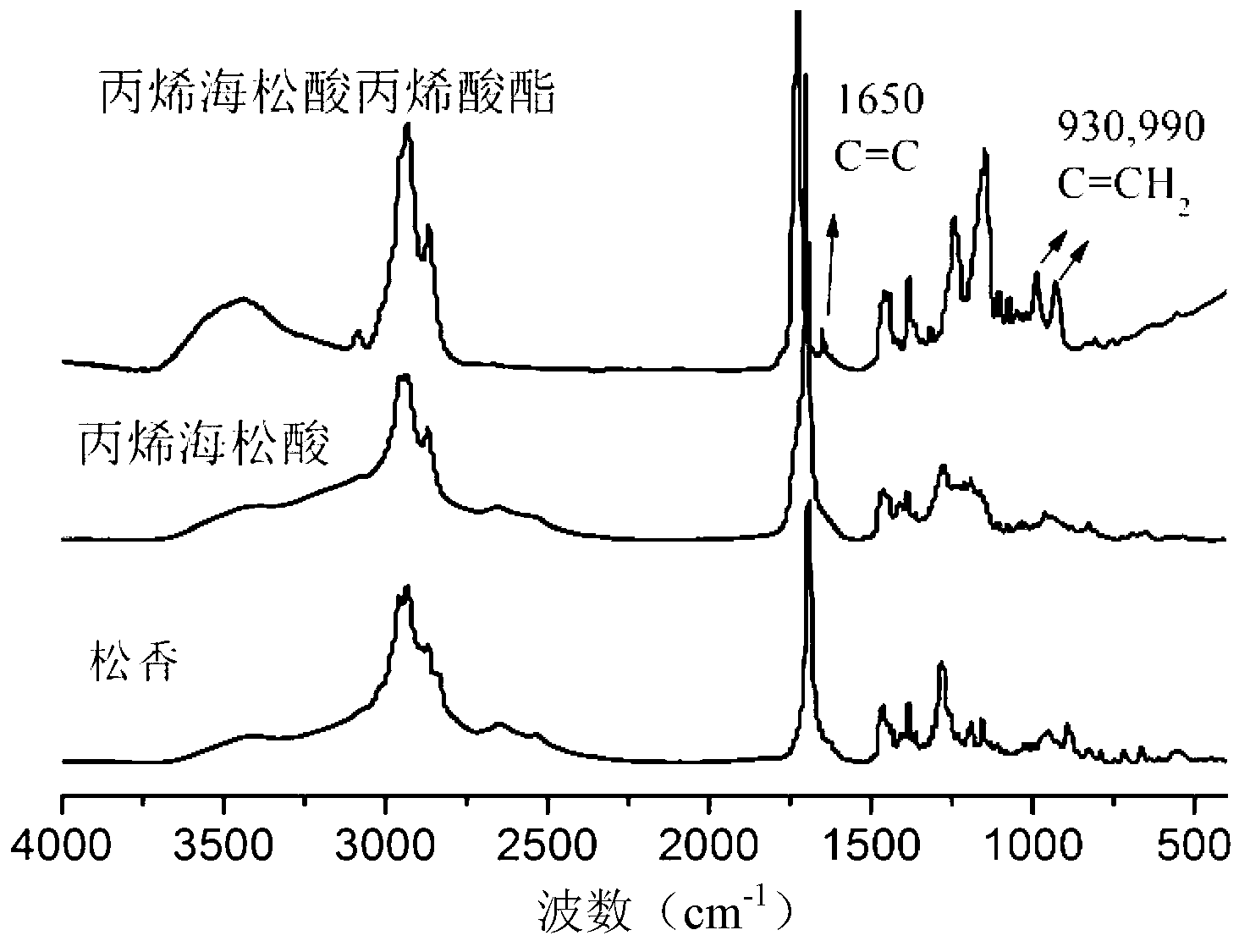

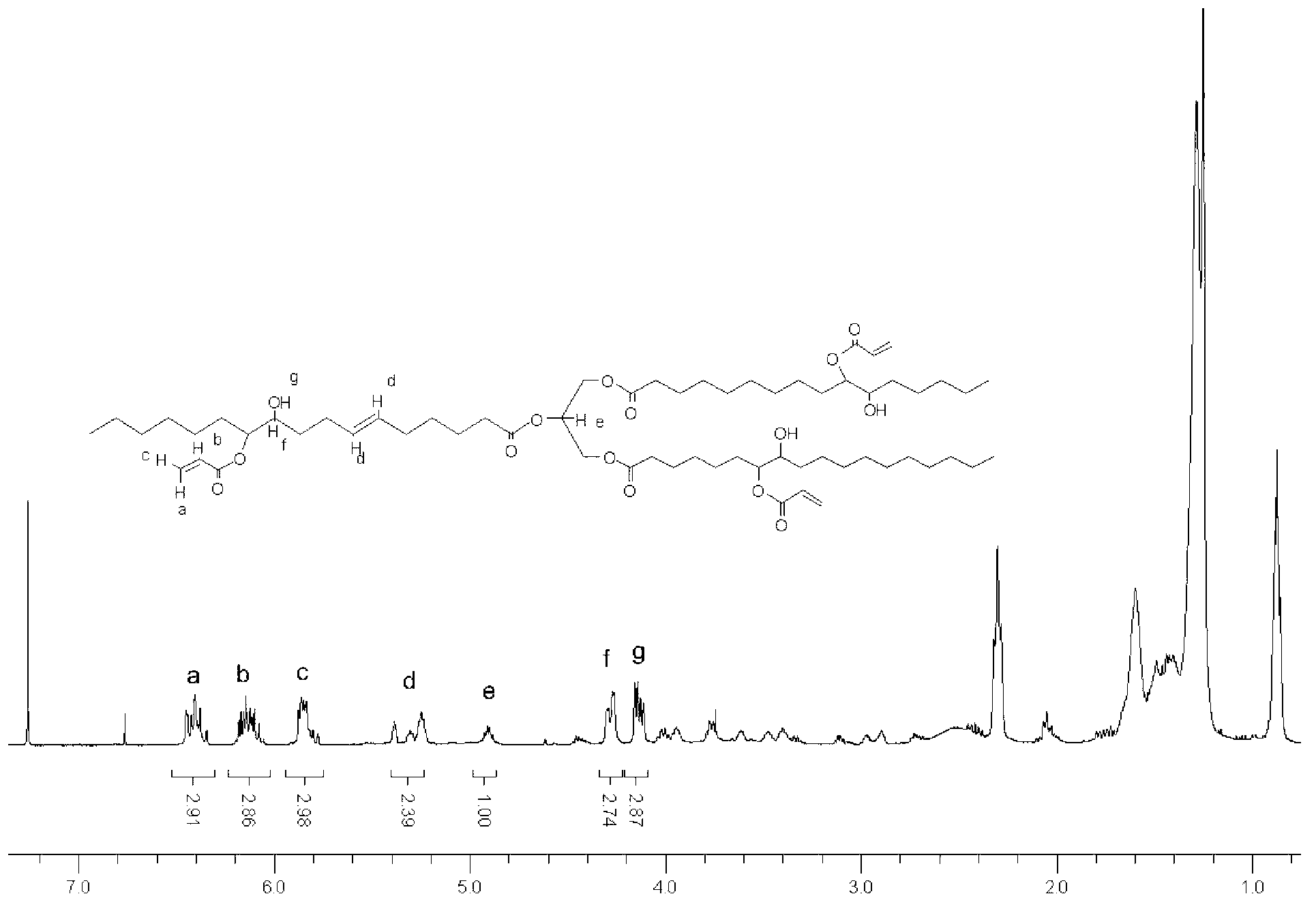

[0046] Example 1 (Synthesis of propylene pimaric acid dipropylene)

[0047] 1) 60g of industrial rosin (Chengdu Grecia Chemical Technology Co., Ltd., purity>99%) is ground and passed through a 50-mesh sieve to obtain a powder, 30g of acrylic acid and 2g of hydroquinone are added as polymerization inhibitors, under the protection of nitrogen, The reaction was stirred at 160°C for 12 hours. After the reaction, the temperature was lowered to 25°C, and 100 mL of ether was added and dissolved in an ultrasonic instrument. Then add 400mL petroleum ether, filter to obtain white precipitate, rinse with petroleum ether and deionized water several times, and finally vacuum dry to obtain 42g white solid product (namely propylene pimaric acid);

[0048] 2) Add 96g of bromopropylene, 56g of potassium carbonate and 100mL of acetone to the 37.4 white solid product, and react with magnetic stirring at 70°C for 24 hours. The resulting product is washed with water, separated, and the organic phase is...

Embodiment 2

[0052] Example 2 (Synthesis of propylene pimaric acid dipropylene)

[0053] 1) 60g of industrial rosin (Chengdu Grecia Chemical Technology Co., Ltd., purity>99%) was ground and sieved to 50 mesh to obtain powder, 15g of acrylic acid and 0.3g of hydroquinone were added as polymerization inhibitors, under nitrogen protection , The reaction was stirred at 180°C for 12 hours. After the reaction, the temperature was lowered to 20°C, and 100 mL of ether was added and dissolved in an ultrasonic instrument. Then add 400 mL petroleum ether, filter to obtain a white precipitate, rinse with petroleum ether and deionized water several times, and finally vacuum dry to obtain 43 g of white solid product (ie, propylene pimaric acid).

[0054] 2) Add 48g of bromopropylene, 28g of potassium carbonate and 100mL of acetone solvent to 37.4g of white solid product, and react with magnetic stirring at 70°C for 6 hours. The resulting product is washed with water, separated into liquids, and the organic p...

Embodiment 3

[0056] Example 3 (Synthesis of propylene pimaric acid dipropylene)

[0057] 1) Grind 1kg of industrial rosin (Chengdu Grecia Chemical Technology Co., Ltd., purity>99%) and pass through a 50-mesh sieve to obtain powder, add 300g acrylic acid and 20g hydroquinone as polymerization inhibitors, under nitrogen protection, The reaction was stirred at 140°C for 2 hours, and then heated to 180°C for 12 hours. After the reaction, the temperature was lowered to 30°C, and 1L of ether was added and dissolved under shaking. Then add 3.5L of excess petroleum ether, filter to obtain a white precipitate, rinse with petroleum ether and deionized water several times, and finally vacuum dry to obtain 650 g of white solid product (ie, propylene pimaric acid).

[0058] 2) Then add 1.5kg of bromopropene and 1L of acetone solvent to 600g of white solid product, add dropwise a concentrated sodium hydroxide aqueous solution (10mol / L) containing 500g of sodium hydroxide at 60°C, and react for 24 hours unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com