Low-smoke flame-retardant polymer composite material and preparation method thereof

A composite material, low-smoke and flame-retardant technology, applied in the field of polymer materials, to achieve the effects of reducing smoke release, enhancing compactness, enhancing flame-retardant and smoke-suppressing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

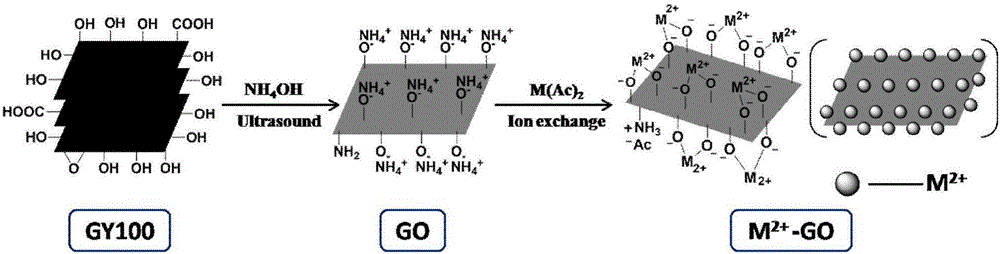

[0059] Furthermore, the preparation method of the hybrid comprises the following steps:

[0060] (1) adding graphite oxide and deionized water into the reactor, adding a weak base dropwise to adjust the pH value of the solution to 7-8, peeling off the graphite oxide under ultrasonic oscillation and microwave heating to obtain a graphene oxide suspension;

[0061] (2) Add the metal salt into the graphene oxide suspension according to the metering, continue to peel off under ultrasonic oscillation and microwave heating until the concentration of the suspension is stable, and then stop to obtain the mixed solution; in the whole process, adjust the pH with a weak base to control the pH =7~8;

[0062] (3) After the peeling is completed, transfer the mixed solution to other reactors, control the temperature at 30-60° C., stir for 8-24 hours, filter after the stirring, wash with water at least 3 times (preferably 3-6 times), Wash with an organic solvent at least 3 times (preferably ...

Embodiment 1

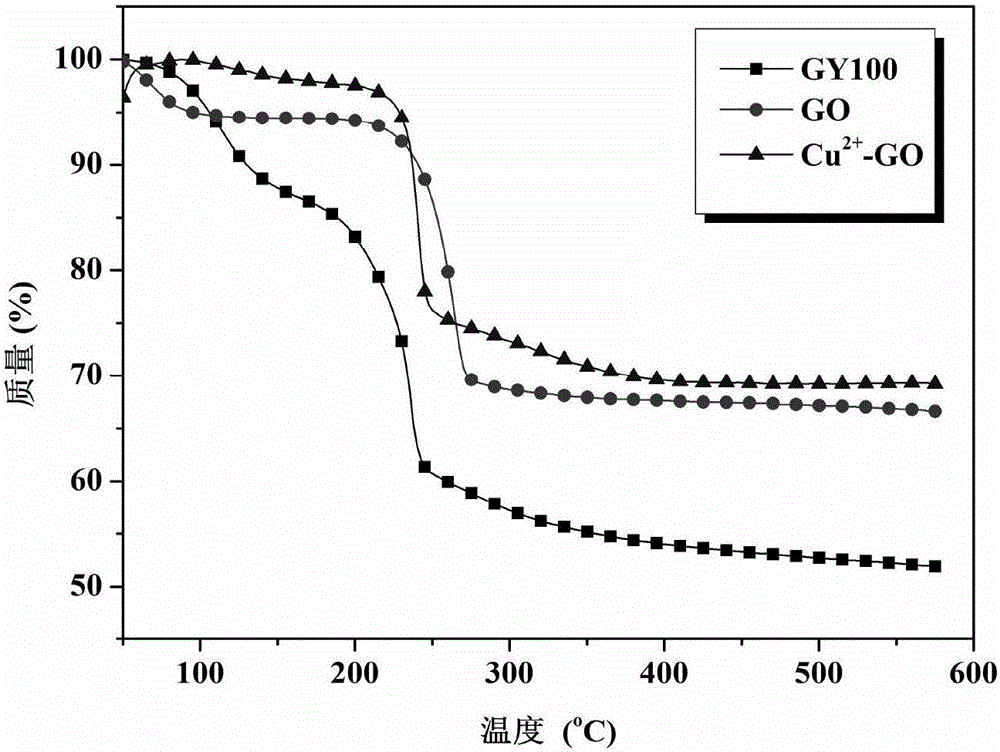

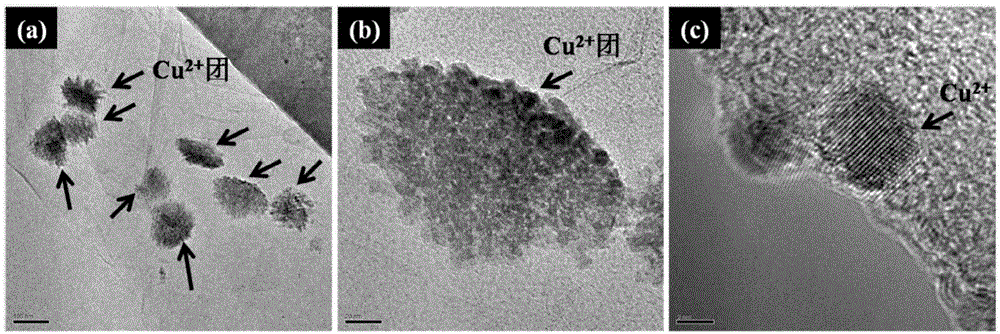

[0066] Example 1 Preparation of Graphene Oxide Supported Metal Ion Hybrid

[0067] Add 1g of graphite oxide (GY100) and 200mL of deionized water into the five-necked glass bottle matched with the ultrasonic microwave linkage instrument, add ammonia water dropwise to make the pH of the solution between 7 and 8, and shake it under ultrasonic vibration (the amount of ultrasonic crushing is 200mL, and the ultrasonic vibration When different horns emit ultrasonic waves to oscillate and break, the corresponding optimal crushing amount is certain, and the crushing amount is measured by volume. Therefore, the crushing amount of the horn is the same as the volume of the solution)) and microwave heating (heating temperature 30° C.) under the action of peeling for 1.5 hours to obtain a graphene oxide suspension with a mass concentration of 0.0050 g / mL;

[0068] Then add 2g of copper acetate to the suspension, and continue peeling off for 1 hour under ultrasonic vibration and microwave he...

Embodiment 2

[0071] Example 2 Preparation of Graphene Oxide Supported Metal Ion Hybrid

[0072] Add 0.5g of graphite oxide (GY100) and 300mL of deionized water into the five-necked glass bottle matched with the ultrasonic microwave linkage instrument, add ammonia water dropwise to make the pH value of the solution between 7 and 8, and shake it under ultrasonic vibration (the amount of ultrasonic crushing is 300mL) and Microwave heating (heating temperature 40°C) was used to peel off for 1 hour to obtain a graphene oxide suspension with a mass concentration of 0.0017g / mL;

[0073] Then add 1.5g cobalt acetate to the suspension, and continue to peel off for 1 hour to obtain the mixed solution under ultrasonic vibration and microwave heating. During the peeling process, measure the pH value of the mixed solution. 7~8;

[0074] Transfer the stripped mixed solution to a 500mL three-necked flask and stir at 50°C for 9h. After the stirring is completed, filter, wash with water 5 times, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com