High-dimension-stability and friction-resistant polyether-ether-ketone composite material and preparation method thereof

A technology of dimensional stability and polyetheretherketone, applied in the field of high dimensional stability and abrasion-resistant polyetheretherketone composite materials and its preparation, can solve the problems of low linear expansion coefficient and molding shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] in N 2 Under protection, dissolve 6g of each of the three high-temperature-resistant coupling agents g-R, g-A, and g-S in 300ml of organic solvent DMF, then add 100g of wollastonite, stir, and heat to the reflux temperature of 152°C, then add 5ml of water to the system , continue to heat and reflux for 1 hour, filter with suction, wash the obtained modified wollastonite with DMF for 3 times, and dry in a vacuum oven at 80° C. to remove the organic solvent. Mix 100 g of the obtained modified wollastonite with 900 g of polyether ether ketone powder, pre-mix uniformly in a high-speed mixer, and then granulate through a twin-screw extruder to obtain the polyether ether ketone composite material of the present invention .

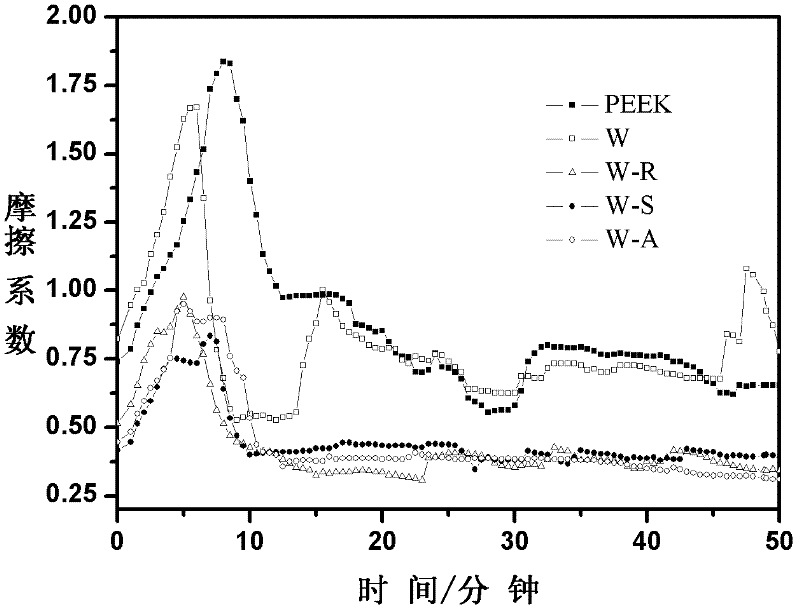

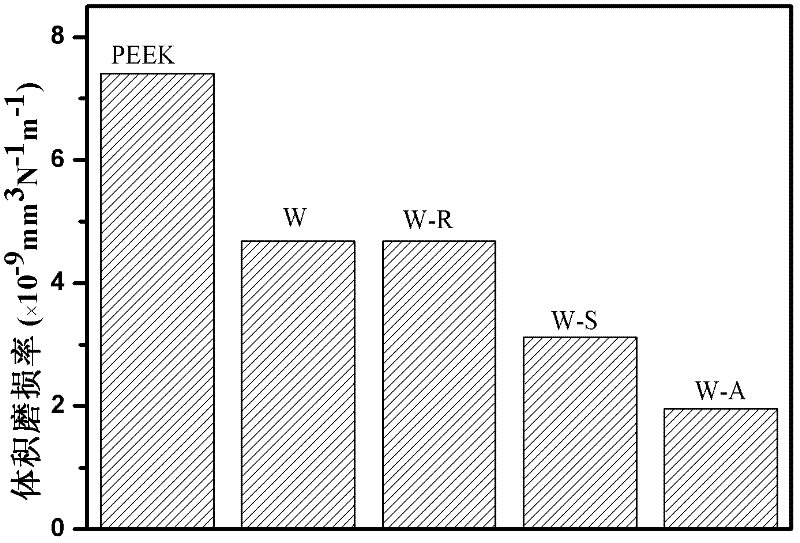

[0040] The linear expansion coefficient of each component material is shown in Table 1. Since wollastonite itself has a low linear expansion coefficient, and the good interfacial interaction provided by the high-temperature resistant coupling agent great...

Embodiment 2

[0045] The PEEK powder of unmodified wollastonite 400g and 600g is mixed uniformly on the high-speed mixer, adds the feed funnel of twin-screw extruder, then uses twin-screw extruder to extrude, granulates, obtains 1000g wollastonite content is 40 wt% of pellets 1;

[0046] Add 600g of REEK powder into the feeding hopper of the twin-screw extruder, introduce 400g of continuous glass fiber from the first exhaust port of the twin-screw, and then use the twin-screw extruder to extrude and granulate to obtain 1000g of glass fiber content Be the pellet 2 of 40wt%; The glass fiber used in the present invention is the alkali-free glass fiber that Hangzhou Qiantang River Special Glass Technology Co., Ltd. produces;

[0047] Add 1000g of REEK powder into the feeding hopper of the twin-screw extruder, then use the twin-screw extruder to extrude and granulate to obtain 1000g of pure PEEK pellets 3;

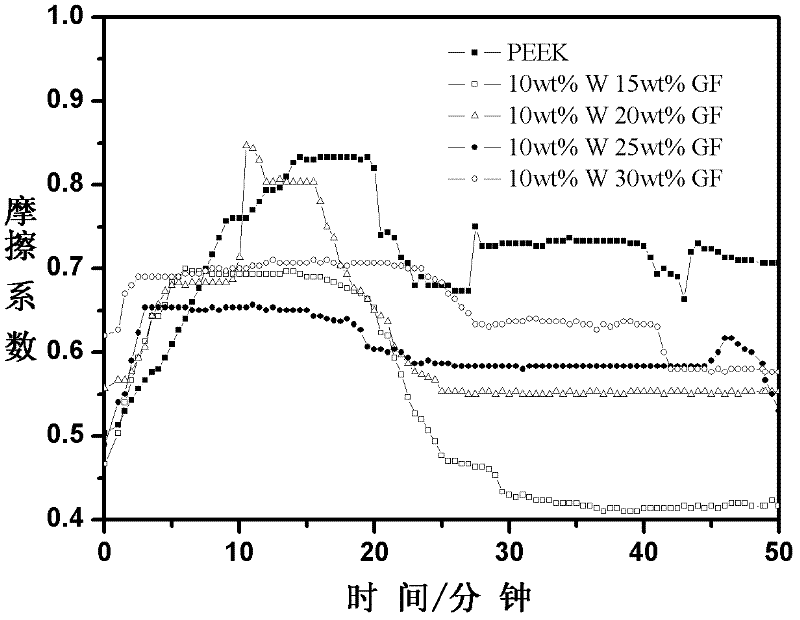

[0048] Take 125g of pellet 1, 500g of pellet 2, and 375g of pellet 3 and mix them unifo...

Embodiment 3

[0050] Get the 250g pellet 1 prepared in Example 2, the 500g pellet 2, and the 250g pellet 3 mix uniformly on a high-speed mixer, add the feeding funnel of the twin-screw extruder, then use the twin-screw extruder to extrude and granulate, A polyetheretherketone composite material containing 10wt% wollastonite and 20wt% glass fiber was obtained, which was denoted as PEEK / 10wt%W / 20wt%GF.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com