Polyimide membranes made of polymerization solutions

a technology of polymerization solution and polymer, which is applied in the field of polymerization solution polymer membranes, can solve the problems of high brittleness of film and membrane produced therefrom, uniform production of polymer membranes only possible with great difficulty, and good separation properties of gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Producing a P84 Type 70 Polyimide Solution in Dimethylacetamide

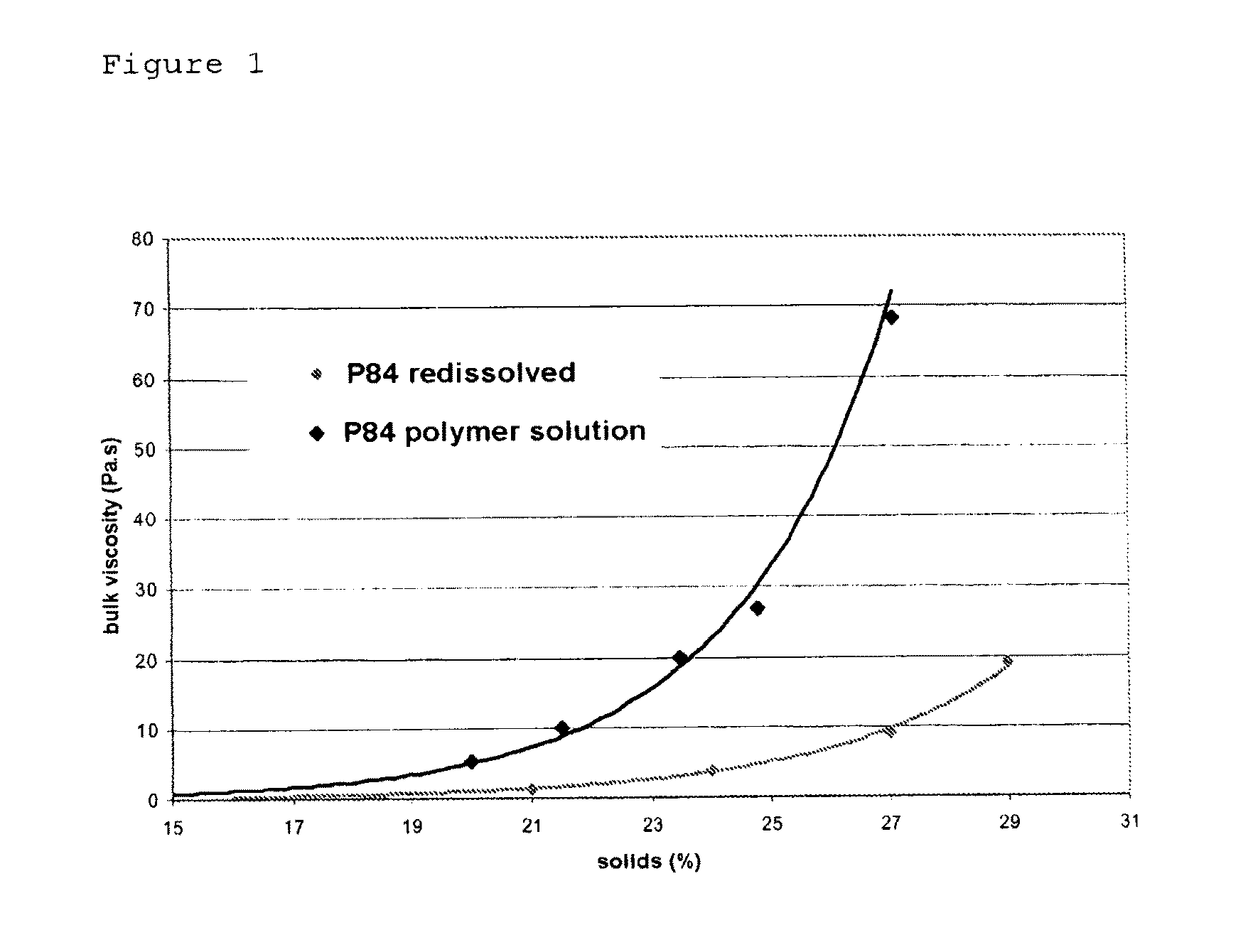

[0115]A 3 l glass reactor equipped with stirrer and reflux condenser is initially charged with 1622 g of anhydrous dimethylacetamide. A quantity of 456.4 g of 3,3′,4,4′-benzophenonetetracarboxylic dianhydride are dissolved therein and the solution is heated to 90° C. To this solution is added 0.45 g of sodium hydroxide. Under nitrogen, 266.8 g of a mixture of 64% of 2,4-tolylene diisocyanate, 16% of 2,6-tolylene diisocyanate and 20% of 4,4′-diisocyanatodiphenylmethane are metered during several hours. In the process, CO2 escapes as by-product and a polyimide results directly in solution.

[0116]The highly viscous solution obtained has a golden color, a solids content of 25% and a viscosity of 49 Pa·s.

[0117]The molar masses are determined by gel permeation chromatography as follows: Mn=80 600 g·mol−1, Mp=139 600 g·mol−1, Mw=170 000 g·mol−1 PDI=2.11

example 2

Producing a P84 Type 70 Polyimide Solution in Dimethylformamide

[0118]A 3 l glass reactor equipped with stirrer and reflux condenser is initially charged with 1622 g of anhydrous dimethylformamide. A quantity of 456.4 g of 3,3′,4,4′-benzophenonetetracarboxylic dianhydride are dissolved therein and the solution is heated to 90° C. To this solution is added 0.45 g of sodium hydroxide. Under nitrogen, 266.8 g of a mixture of 64% of 2,4-tolylene diisocyanate, 16% of 2,6-tolylene diisocyanate and 20% of 4,4′-diisocyanatodiphenylmethane are metered during several hours. In the process, CO2 escapes as by-product and a polyimide results directly in solution.

[0119]The highly viscous solution obtained has a golden color, a solids content of 27% and a viscosity of 48 Pa·s.

[0120]The molar masses are determined by gel permeation chromatography as follows: Mn=76 600 g·mol−1, Mp=130 500 g·mol Mw=146 200 g·mol−1 PDI=1.91

example 3

Producing a P84 Type 70 Polyimide Solution in N-methylpyrrolidone

[0121]A 3 l glass reactor equipped with stirrer and reflux condenser is initially charged with 1800 g of anhydrous N-methylpyrrolidone. A quantity of 456.4 g of 3,3′,4,4′-benzophenonetetracarboxylic dianhydride are dissolved therein and the solution is heated to 90° C. To this solution is added 0.45 g of sodium hydroxide. Under nitrogen, 266.8 g of a mixture of 64% of 2,4-tolylene diisocyanate, 16% of 2,6-tolylene diisocyanate and 20% of 4,4′-diisocyanatodiphenylmethane are metered during several hours. In the process, CO2 escapes as by-product and a polyimide results directly in solution.

[0122]The highly viscous solution obtained has a golden color, a solids content of 25% and a viscosity of 45 Pa·s.

[0123]The molar masses are determined by gel permeation chromatography as follows: Mn=65 700 g·mol−1, Mp=107 200 g·mol−1, Mw=147 000 g·mol−1 PDI=2.24

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com