Liquid crystal phase shift unit for reflected adjustable phase shifter

A phase shifter, reflective technology, applied in electrical components, waveguide devices, circuits, etc., can solve the problems of liquid crystal molecules not completely rotated, phase curve and device test value errors, and values not reaching the ideal value, etc. The effect of improving the electrode loading method, simple main structure and improving the degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

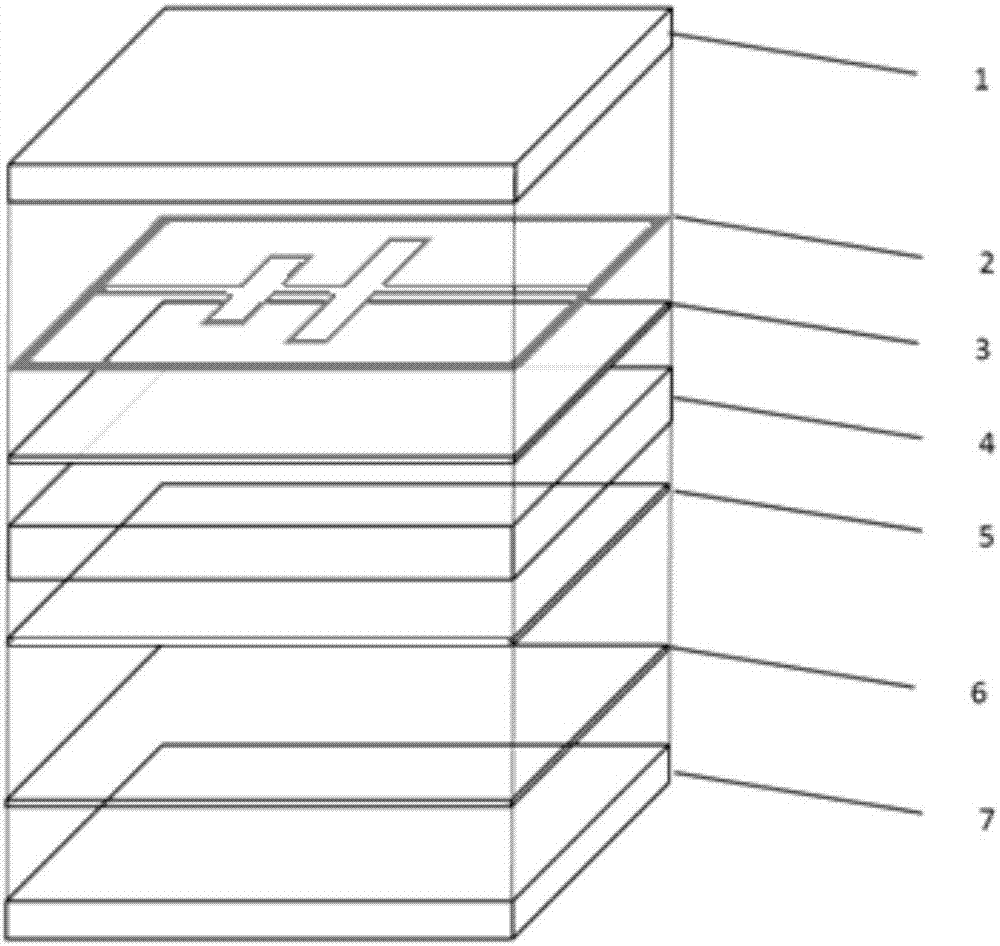

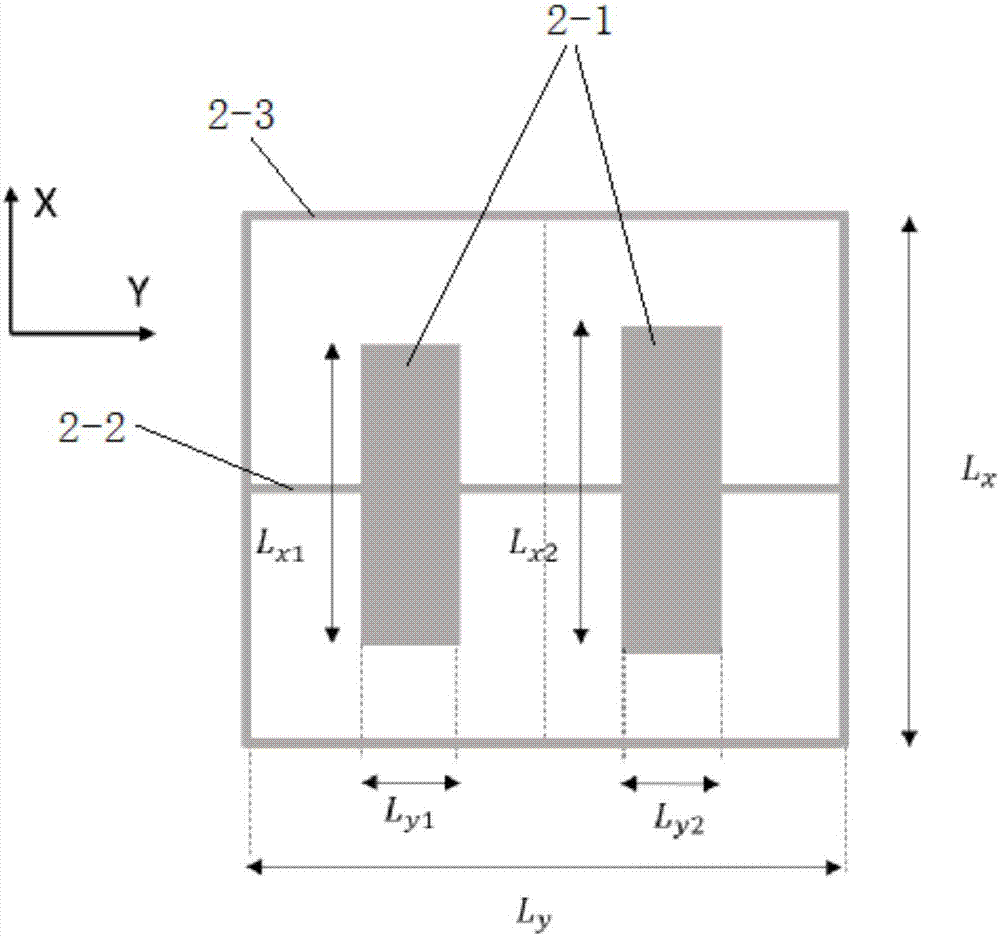

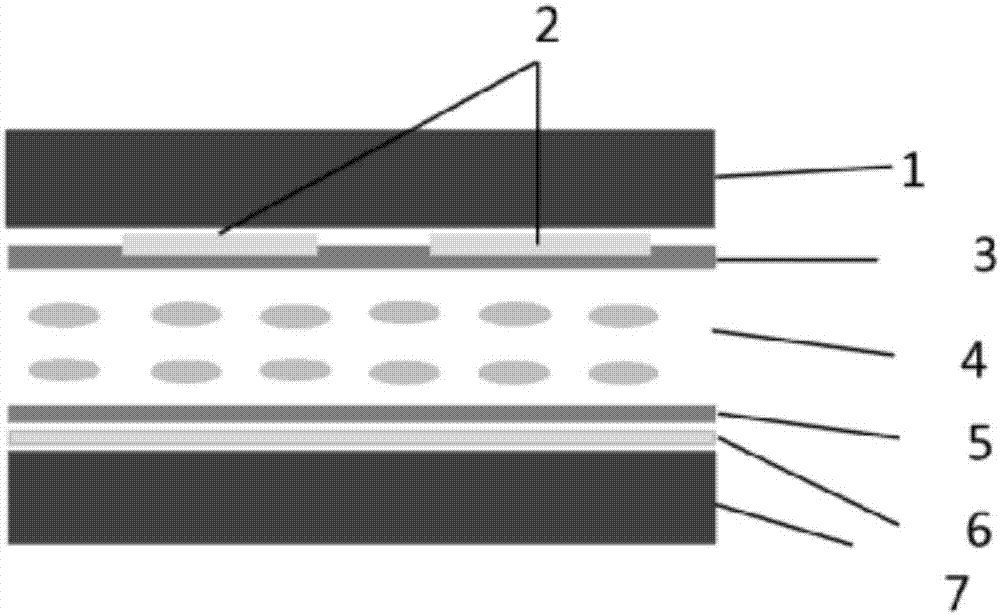

[0018] Such as figure 1 , 2 . As shown in 3, a liquid crystal phase shifting unit for a reflective adjustable phase shifter includes upper and lower two-layer dielectric substrates 1, 7, and the gap between the upper and lower two-layer dielectric substrates 1, 7 is injected with The liquid crystal layer 4, the metal microstrip patch electrode 2 is provided on the lower side of the upper dielectric substrate 1, the metal total reflection ground electrode 6 is provided on the upper side of the lower dielectric substrate 7, and the upper and lower surfaces of the liquid crystal layer 4 are respectively provided with polyamide Imine film coatings 3, 5; the metal microstrip patch electrode 2 includes two identical dipole patches 2-1, a bias voltage loading line 2-2, auxiliary electrodes 2-3, two Two dipole patches 2-1 are arranged in parallel, and the bias voltage loading line 2-2 is orthogonally connected to two dipole patches 2-1 to form a patch unit. The auxiliary electrode 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com