Patents

Literature

44results about How to "No change to the process flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

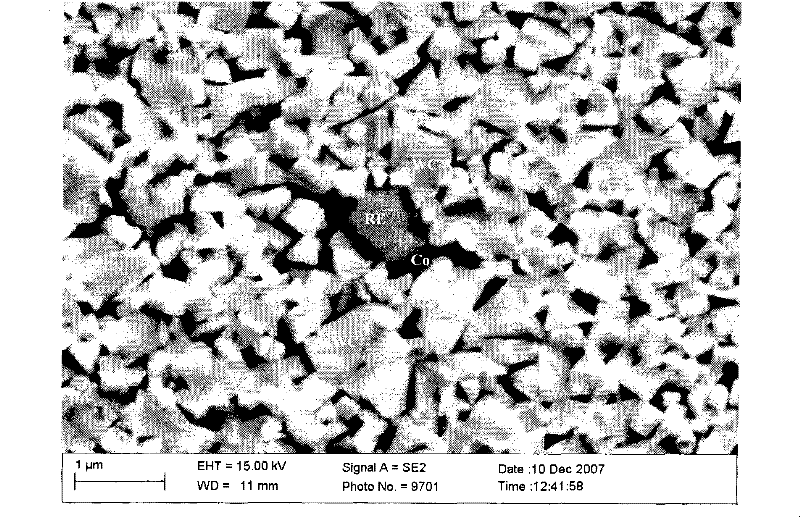

Superfine WC-Co cemented carbide containing rare-earth elements and preparation method thereof

ActiveCN101760685AChange processSteady improvement in overall performanceRare-earth elementChemical reaction

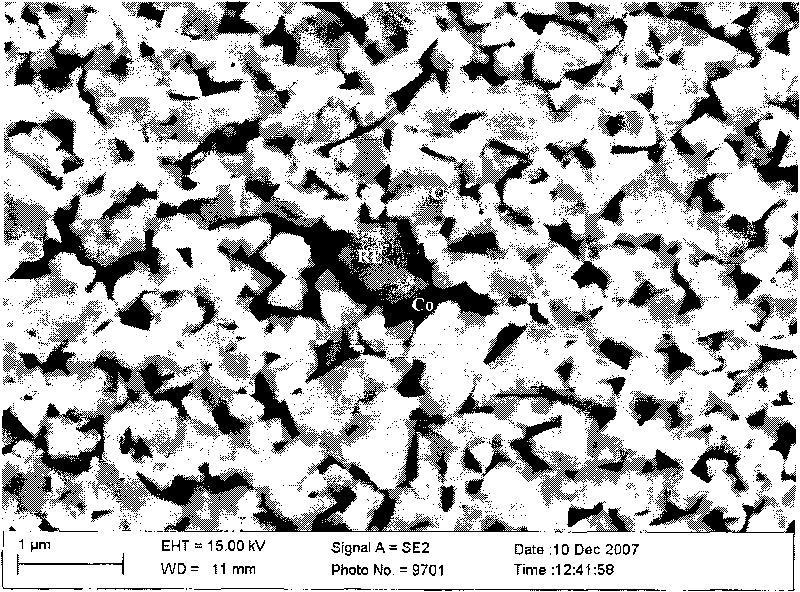

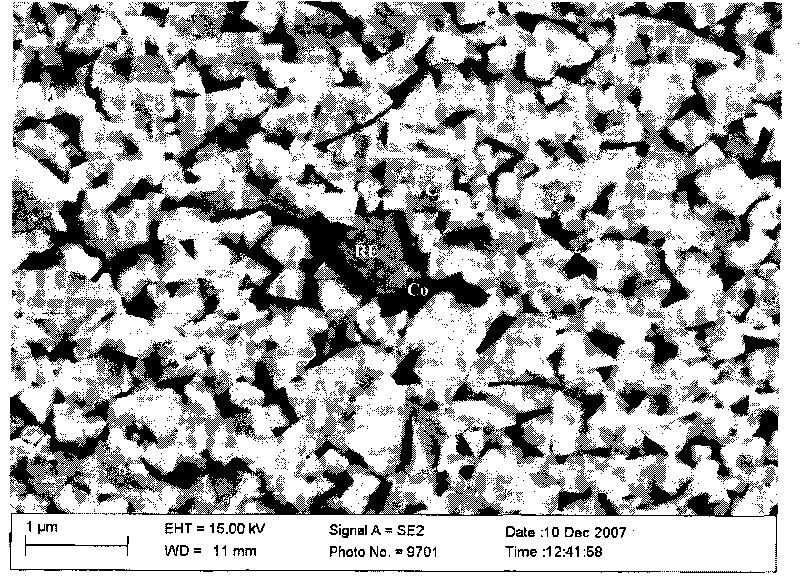

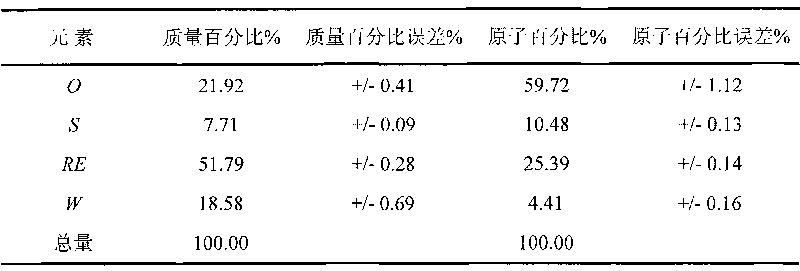

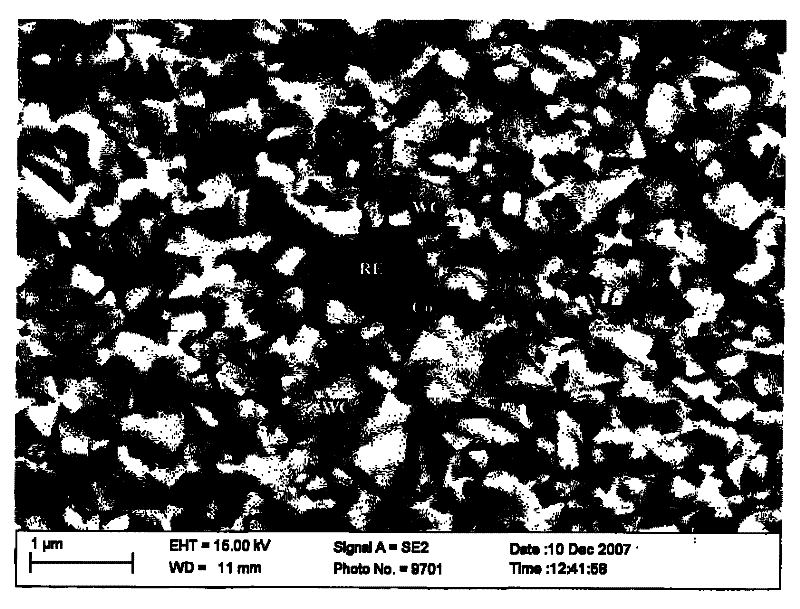

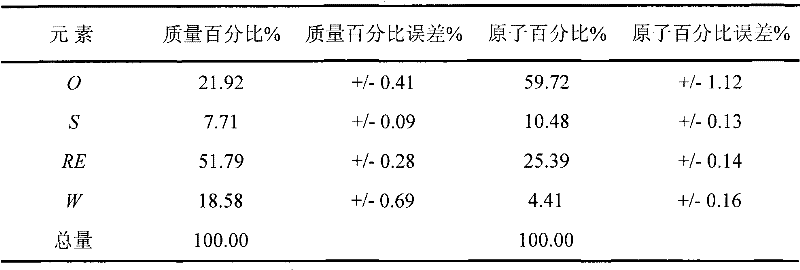

The invention discloses a superfine WC-Co cemented carbide containing rare-earth elements and a preparation method thereof, belonging to the technical field of cemented carbide. In the cemented carbide, the weight of WC rigid phase accounts for 85-94% of that of the cemented carbide, the weight of Co binder phase accounts for 5-14% of that of the cemented carbide, the weight of grain growth inhibitor accounts for 0.3-2.0% of that of the cemented carbide, and the weight of the thulium in the rare earth addition accounts for 0.2-1.2% of that of the Co binder phase. The method comprises the following steps: weighing various powder stocks, ball-milling, drying and pelletizing to form a compound; and suppressing and shaping the compound, sintering and cooling to obtain the cemented carbide. The adding mode of nano rare earth oxide or Co-RE composite powder can be implemented easily and conveniently, and the rare earth is diffusely and evenly distributed, thereby facilitating to perform physo-chemical reactions; and the cemented carbide has the advantages of low production cost, stable and enhanced performance and easy implementation, production and application.

Owner:GRIMAT ENG INST CO LTD

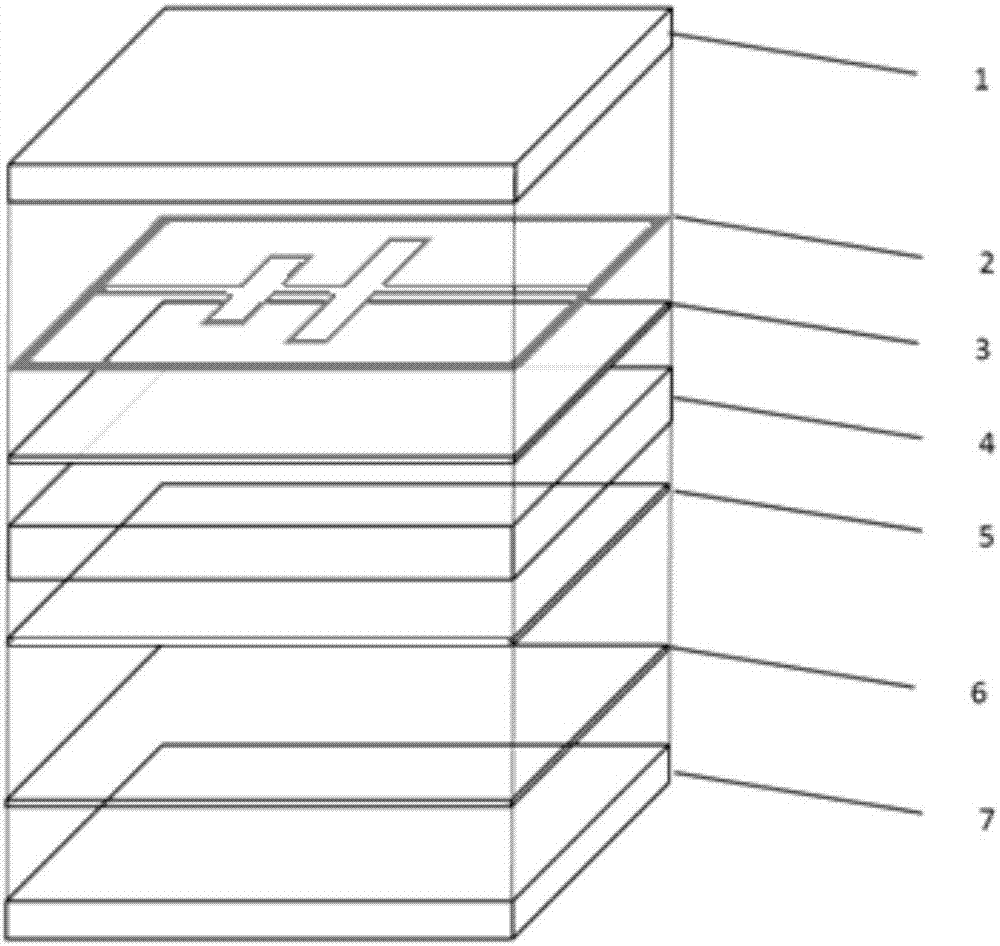

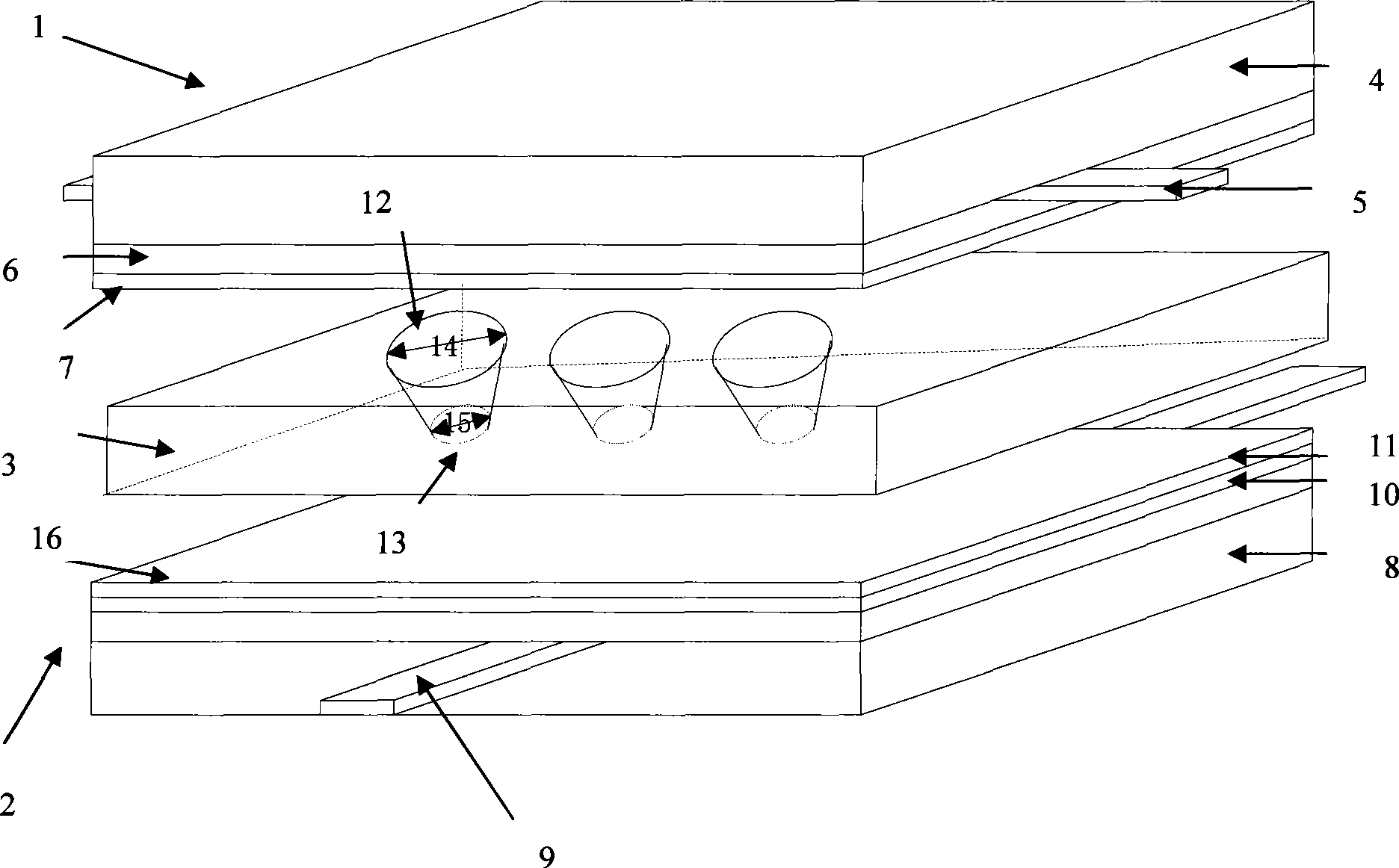

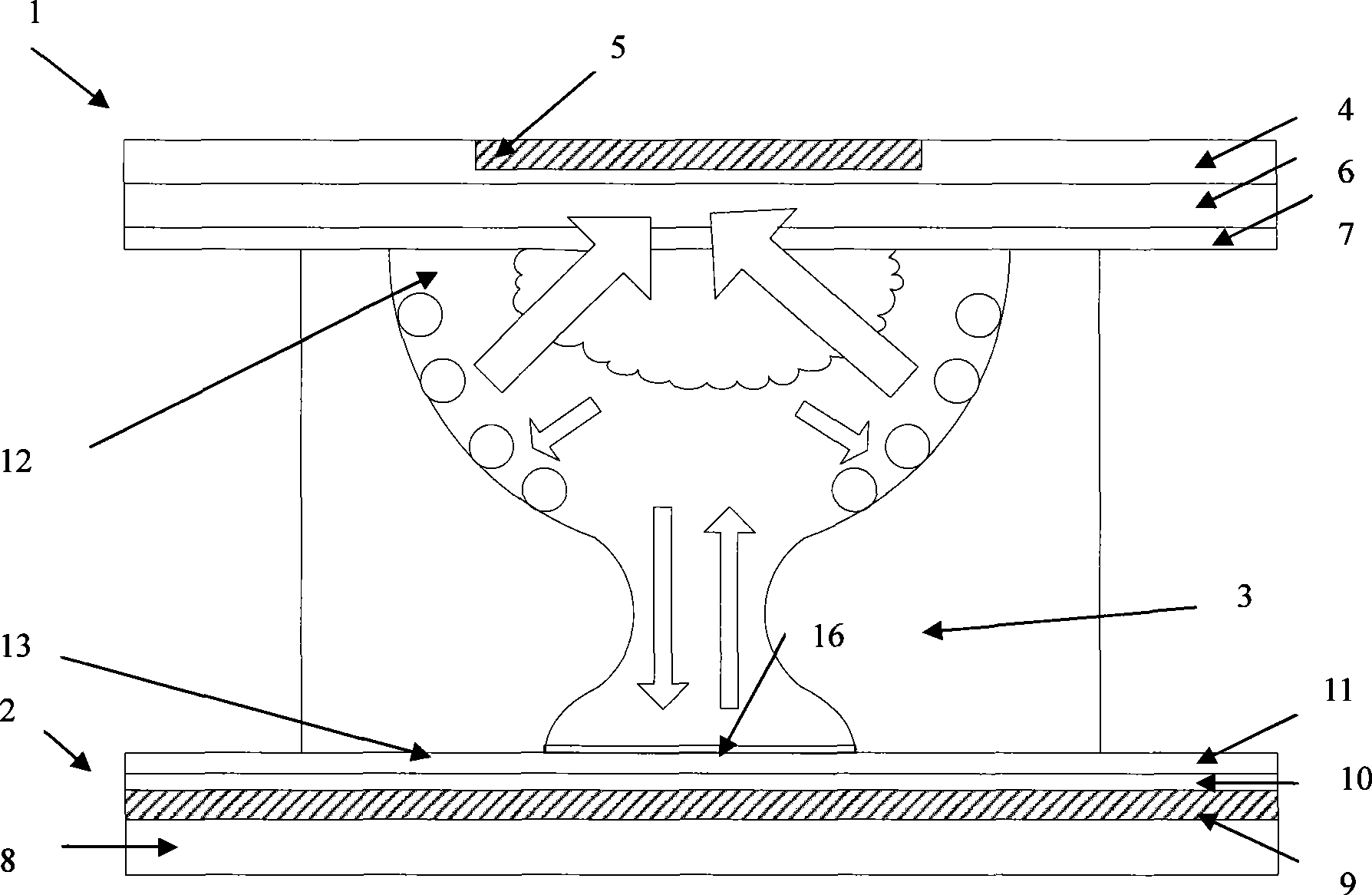

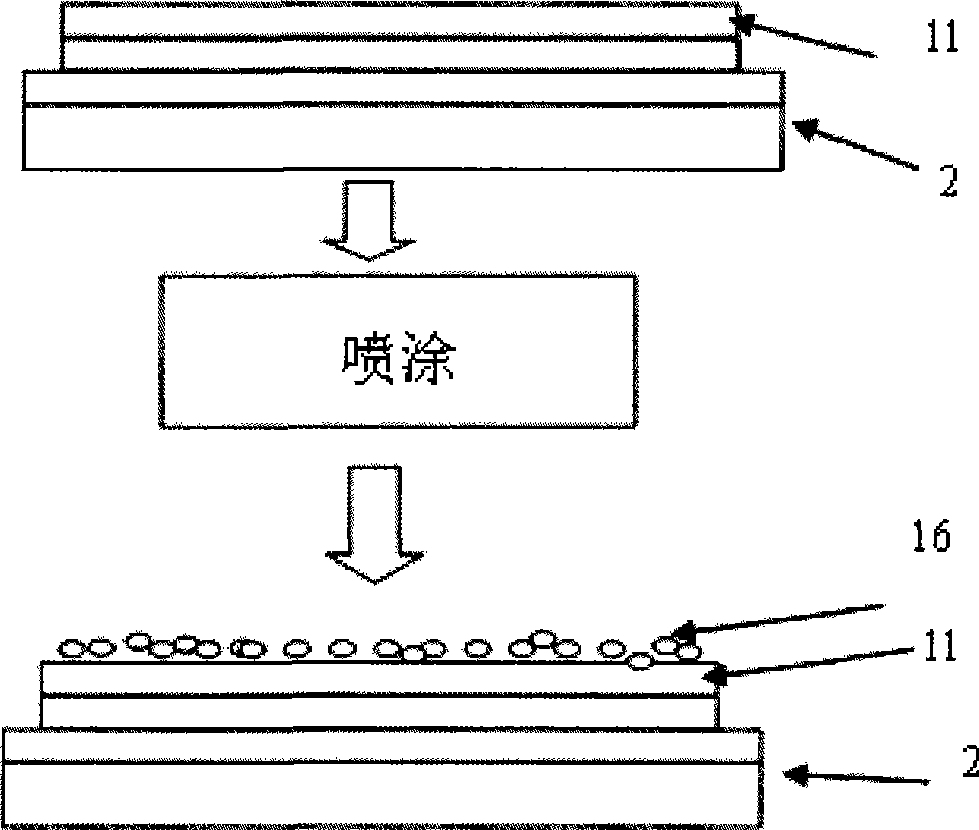

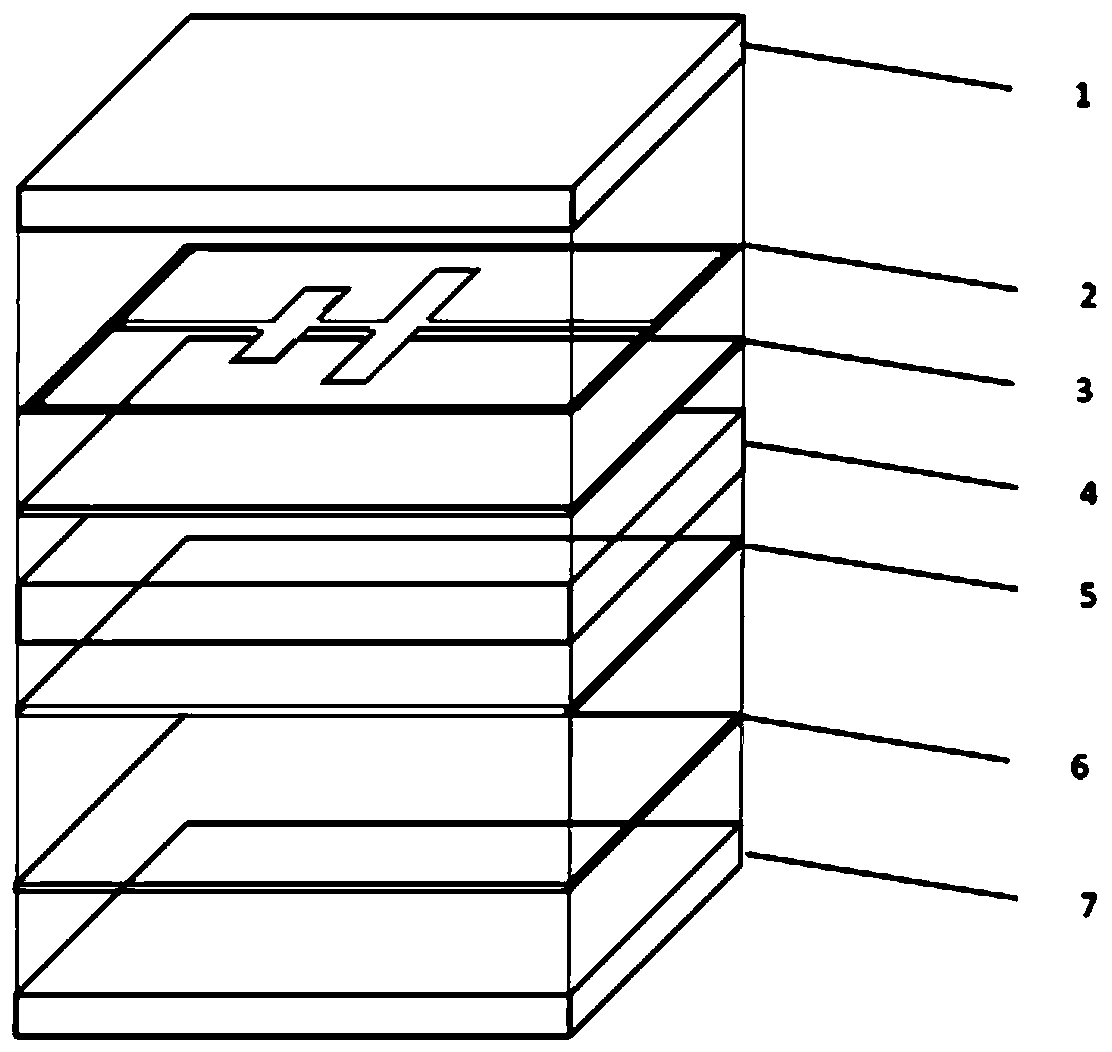

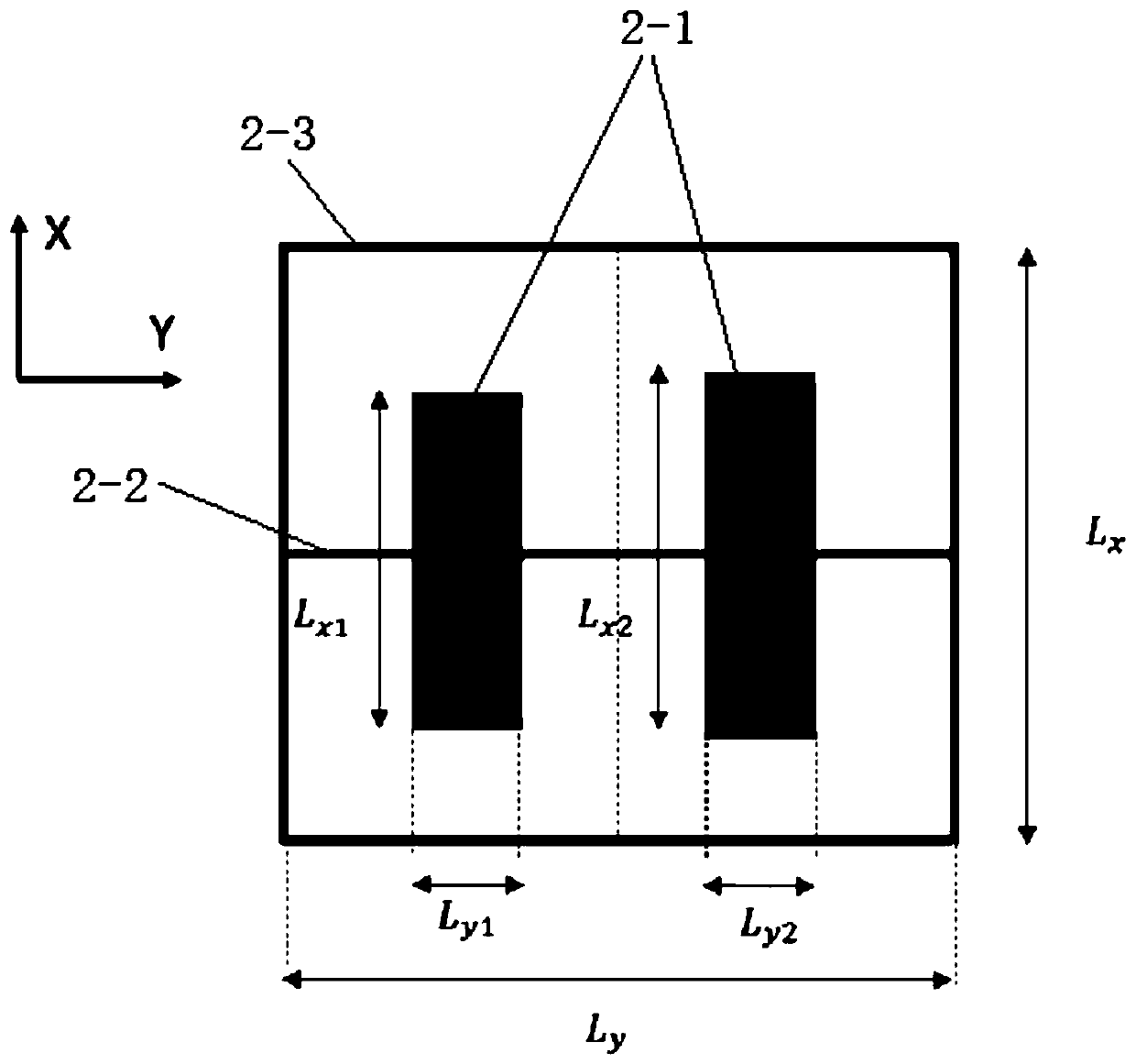

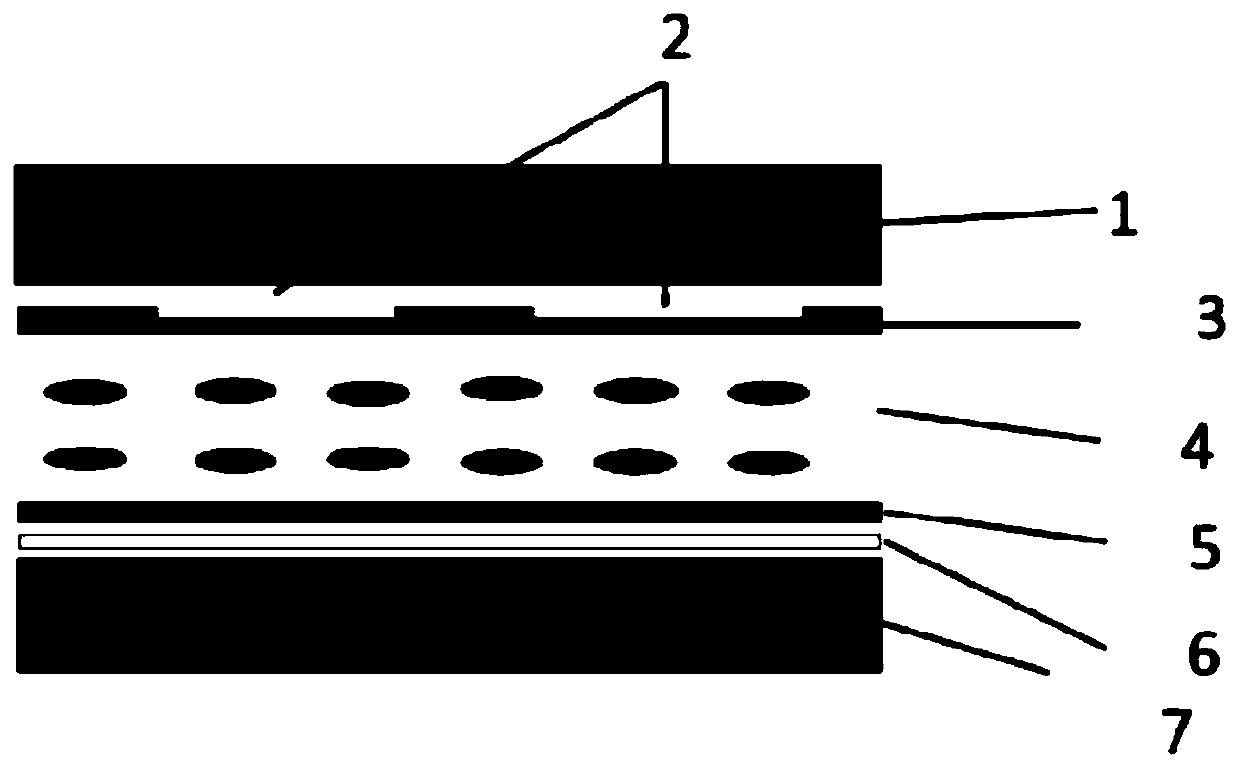

Liquid crystal phase shift unit for reflected adjustable phase shifter

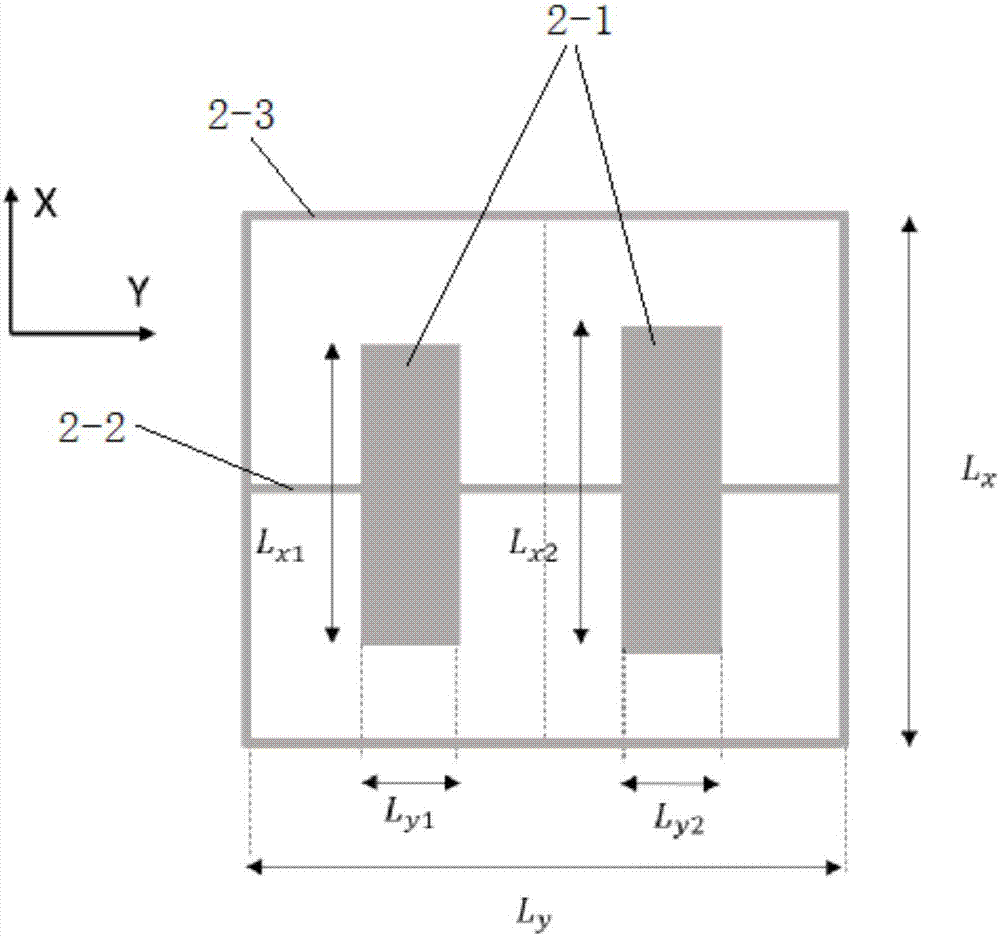

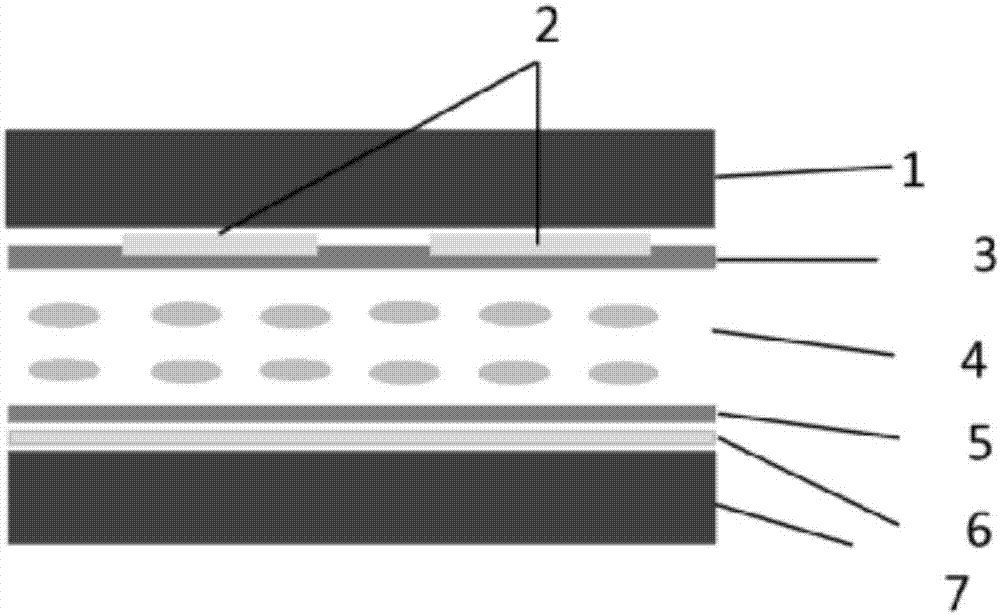

The invention discloses a liquid crystal phase shift unit for a reflected adjustable phase shifter. The liquid crystal phase shift unit comprises two upper and lower layers of medium substrates, a liquid crystal layer is injected in the gap between the two upper and lower layers of medium substrates, a metal microstrip patch electrode is arranged on the lower side of the upper layer medium substrate, a metal total reflection ground electrode is arranged on the upper side of the lower layer medium substrate, and polyimide film coating is respectively arranged on upper and lower surfaces of the liquid crystal layer; the metal microstrip patch electrode comprises two identical dipole patches, an offset voltage loading line and an auxiliary electrode, the two dipole patches are arranged in parallel, the offset voltage loading line is connected with the two dipole patches orthogonally to form a patch unit, the auxiliary electrode is a quadrilateral metal frame, and the quadrilateral metal frame surrounds the whole patch unit and is connected with the offset voltage loading line. The auxiliary electrode has a simple main body structure, educes the saturation bias voltage, and can be used in the field of liquid crystal reflected phase shifters and phase control antennas within microwave, millimeter wave and terahertz frequency bands.

Owner:HEFEI UNIV OF TECH

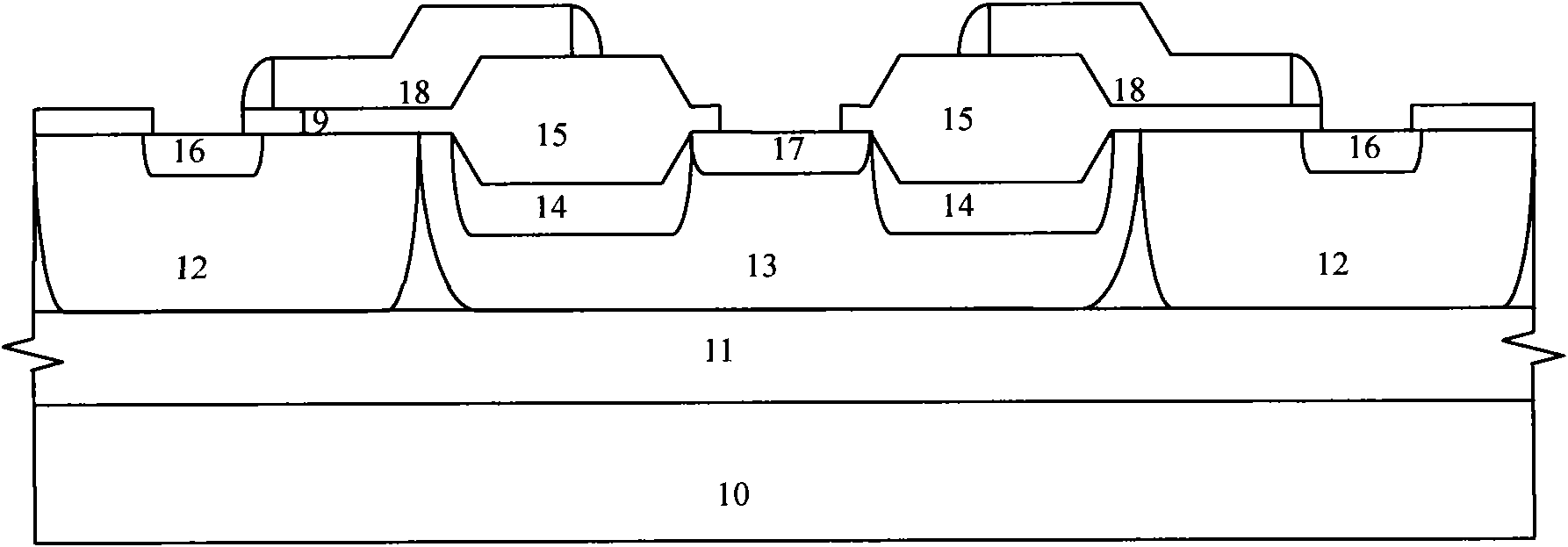

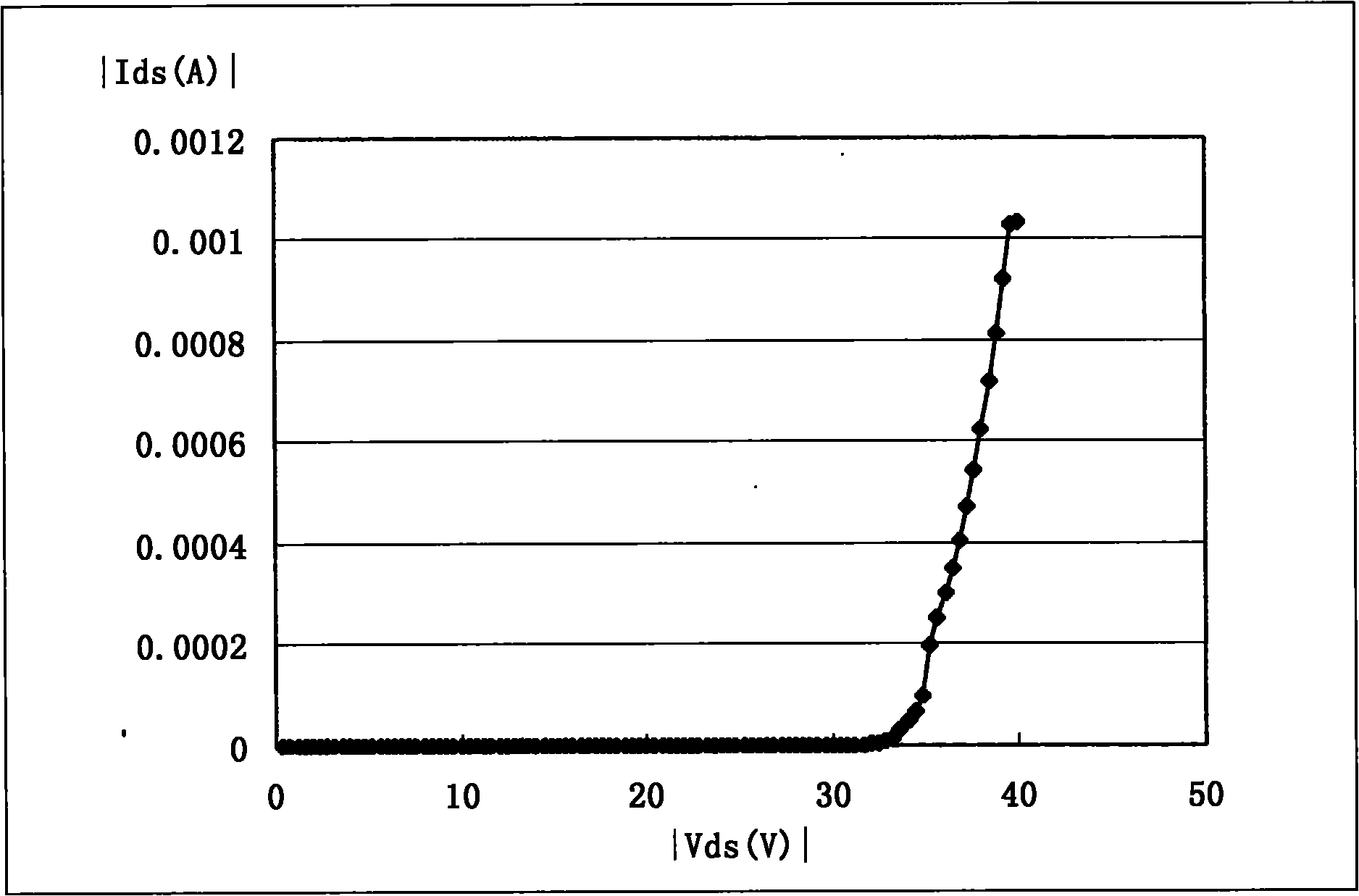

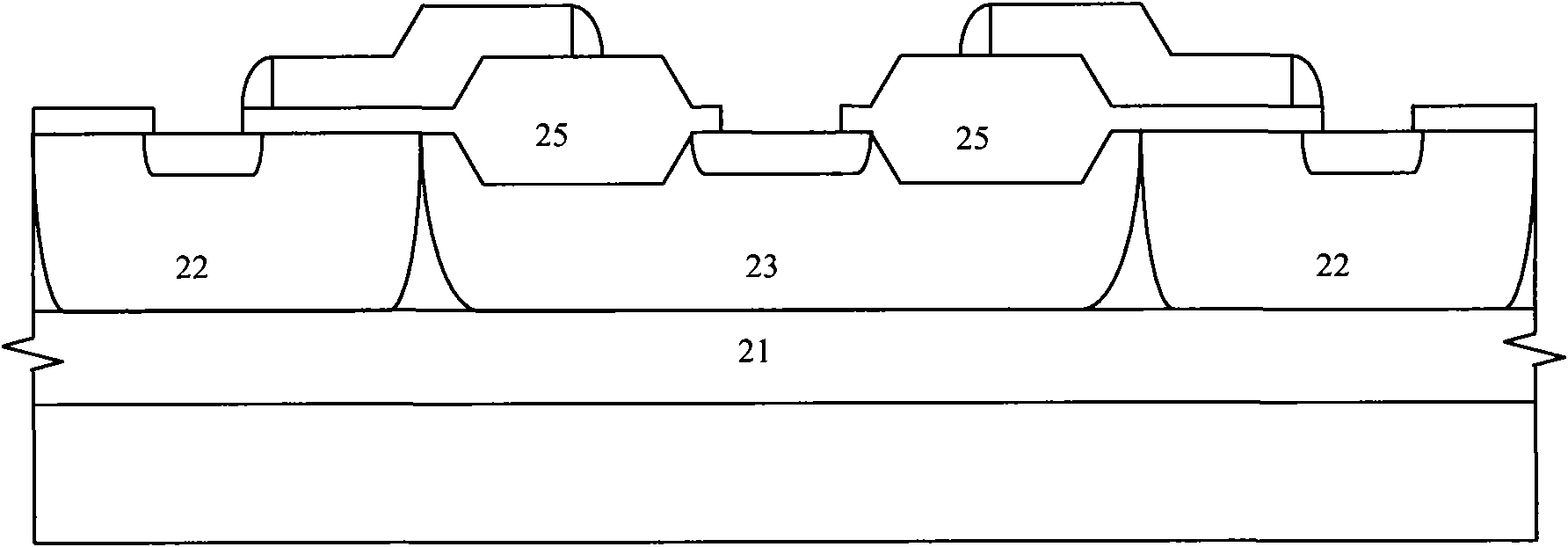

High-voltage semiconductor device and manufacturing method thereof

ActiveCN101916778AKnot depthReduce the amount requiredTransistorSemiconductor/solid-state device manufacturingPhysicsElectric field

The invention provides a high-voltage semiconductor device and a manufacturing method thereof. The high-voltage semiconductor device comprises a substrate, first well regions, second well regions, field injection regions, source regions, drain regions, field oxidization layers, grid oxidization layers and grid electrodes, wherein the first well regions and the second well regions are formed in the substrate; the field injection regions are formed in the first well regions and the second well regions and are both overlapped with the first well regions and the second well regions; the source regions are formed in the first well regions; the drain regions are formed in the second well regions; the field oxidization layers and the grid oxidization layers cover the surface of the substrate, and the field oxidization layers are positioned above the field injection regions; and the grid electrodes are arranged between the source regions and the drain regions and are formed on the field oxidization layers and the grid oxidization layers. The second well regions and the field injection regions of the high-voltage semiconductor device together form a drift region of the high-voltage semiconductor device. When a high voltage is added at a drain end, the field injection regions overlapped with the first well regions can be exhausted, thereby the distribution of an electric field adjacent to a beak is improved, and the breakdown voltage of the semiconductor device is improved. Under the condition of not changing process flows and increasing the manufacturing cost, the breakdown voltage of the semiconductor device is improved to the maximum.

Owner:BCD (SHANGHAI) MICRO ELECTRONICS LTD

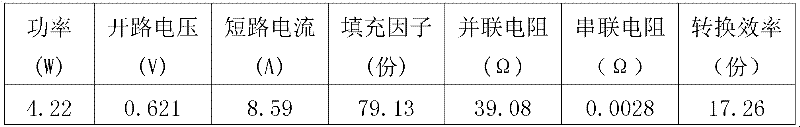

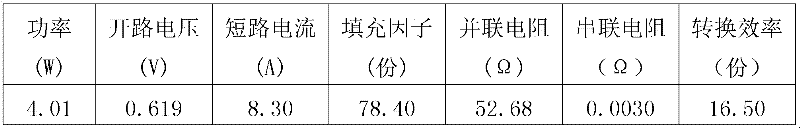

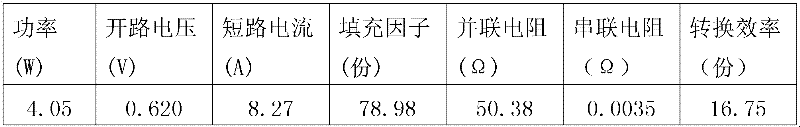

Aluminum paste for improving conversion efficiency of solar cells and preparation method for aluminum paste

InactiveCN102360585AImprove conversion efficiencyImprove electrical performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesiveElectrical performance

The invention relates to aluminum paste for improving the conversion efficiency of solar cells and a preparation method for the aluminum paste. The aluminum paste consists of the following components in part by weight: 60 to 80 parts of aluminum powder, 15 to 40 parts of organic carrier and 2 to 5 parts of inorganic adhesive, wherein the particle size of the aluminum powder is 1 to 10mu m. The invention solves the technical problem that aluminum paste for improving the conversion efficiency of silicon solar cells and a preparation method thereof are provided. By the aluminum paste, the conversion efficiency of the solar cells is averagely improved by 1 time, and the electrical performance is also improved; and the appearance also meets the requirements of the solar cells.

Owner:SHAANXI TIANSHENG NEW MATERIAL TECH

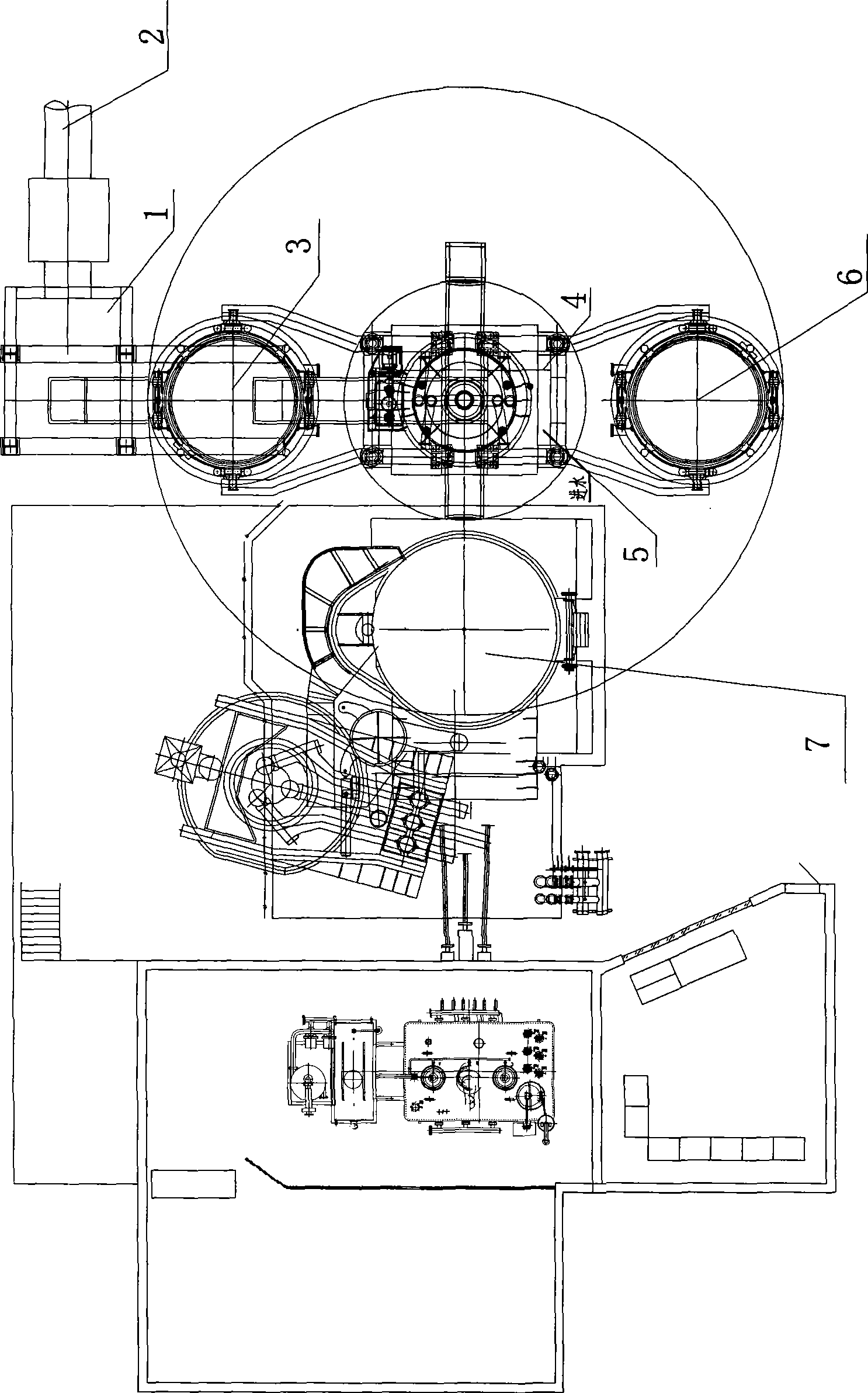

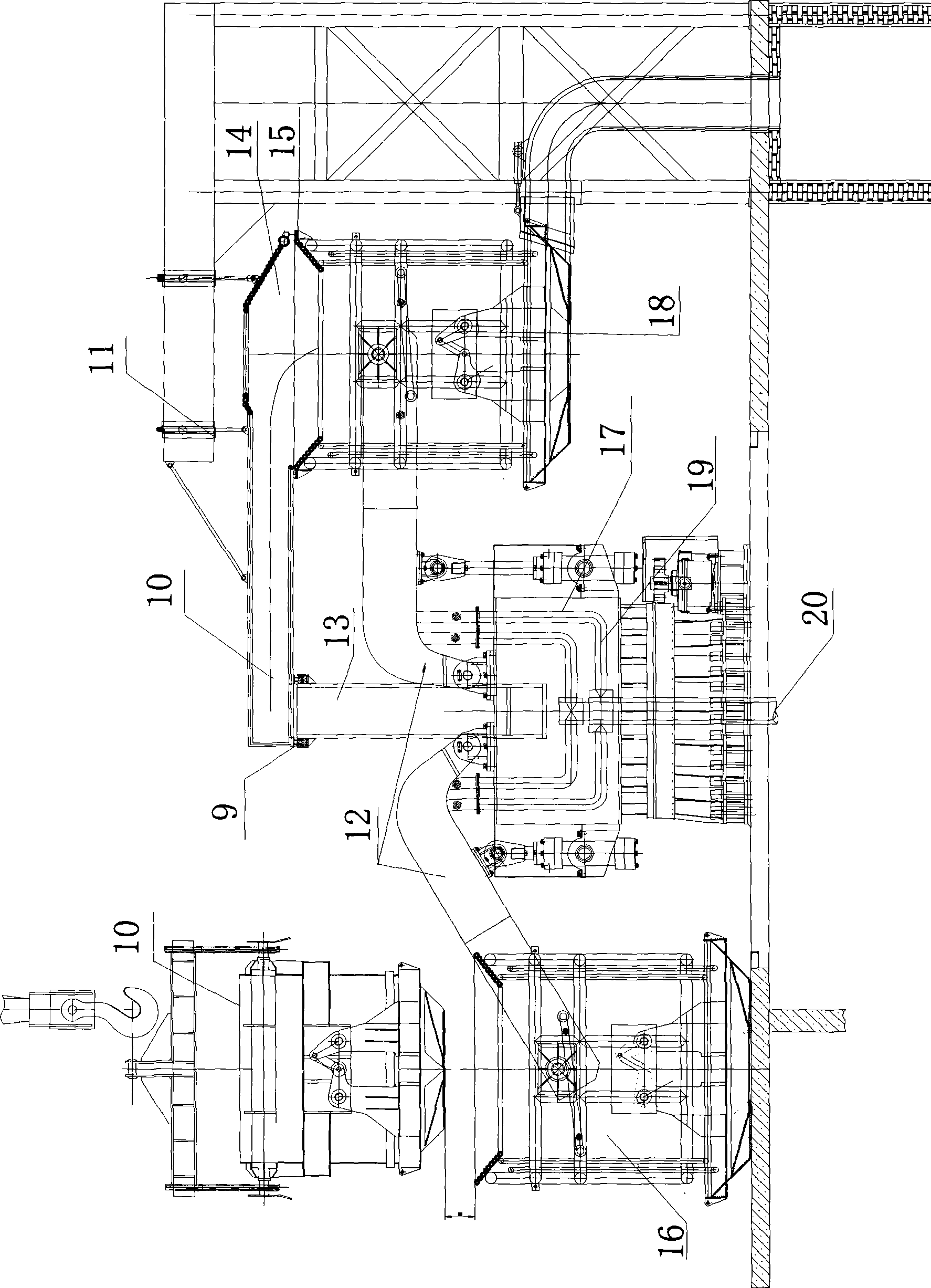

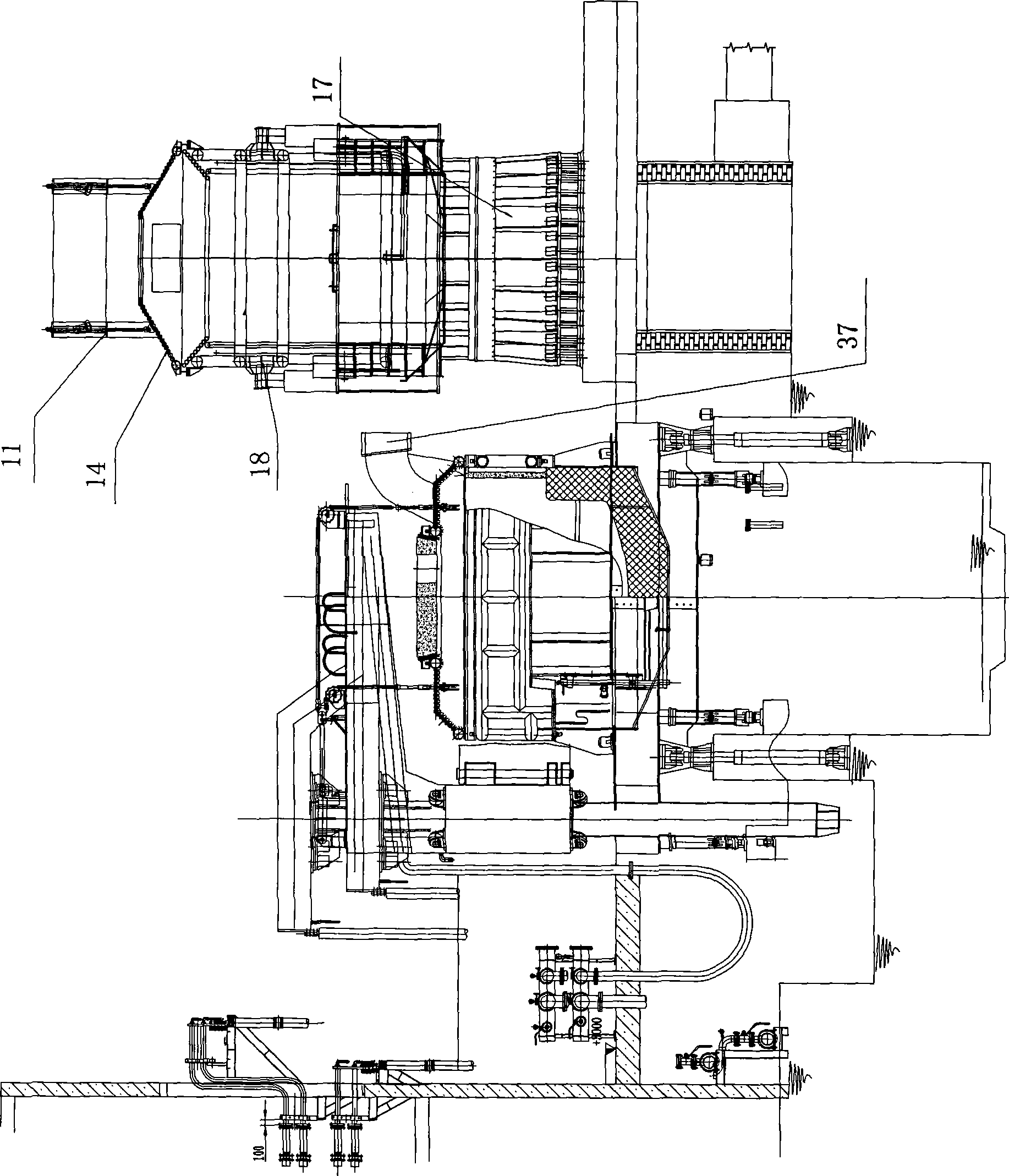

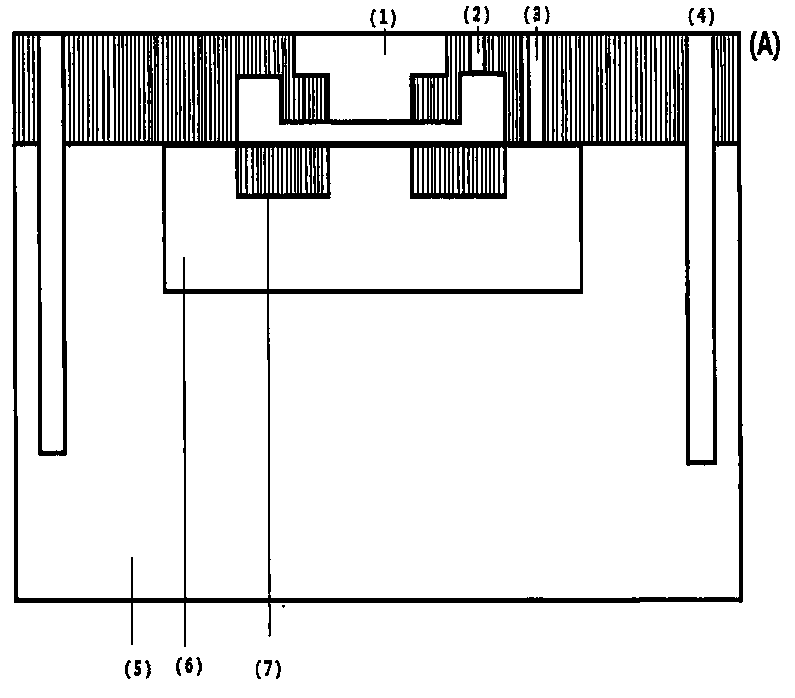

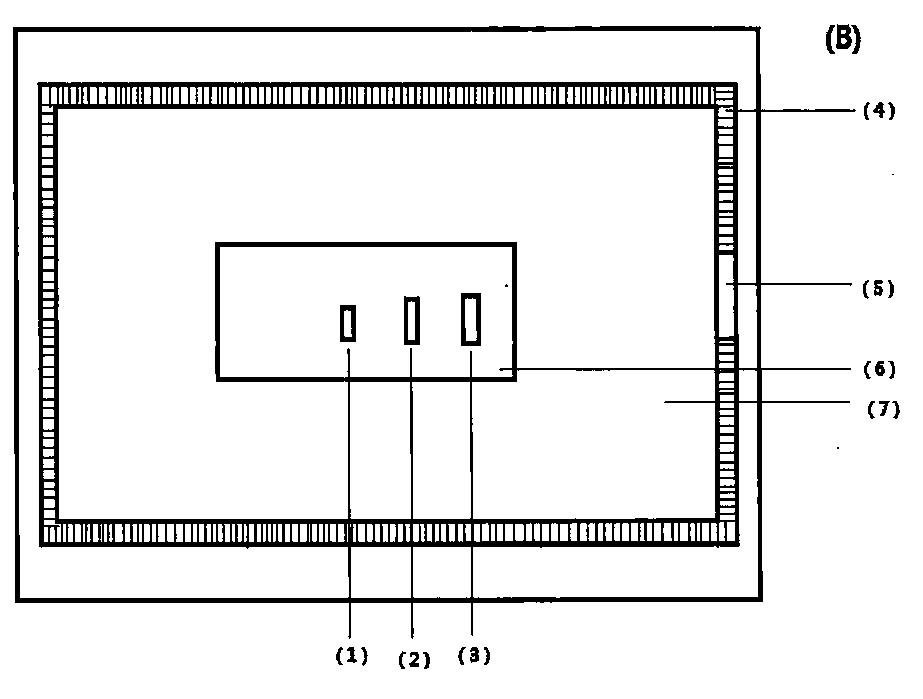

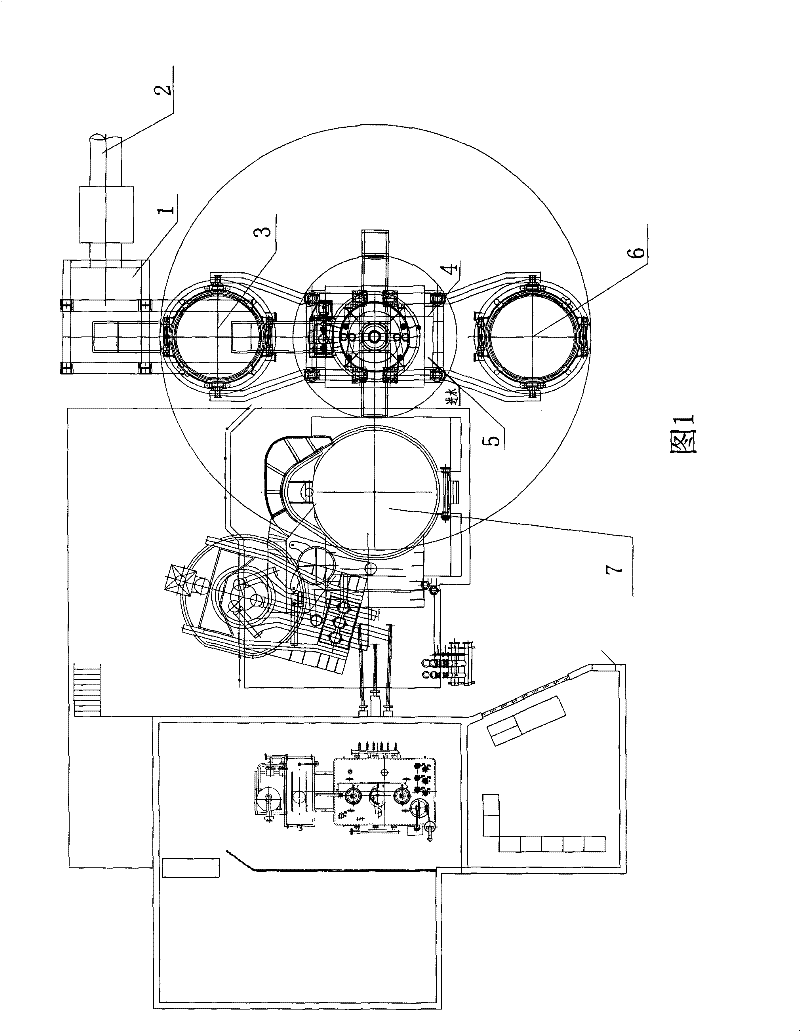

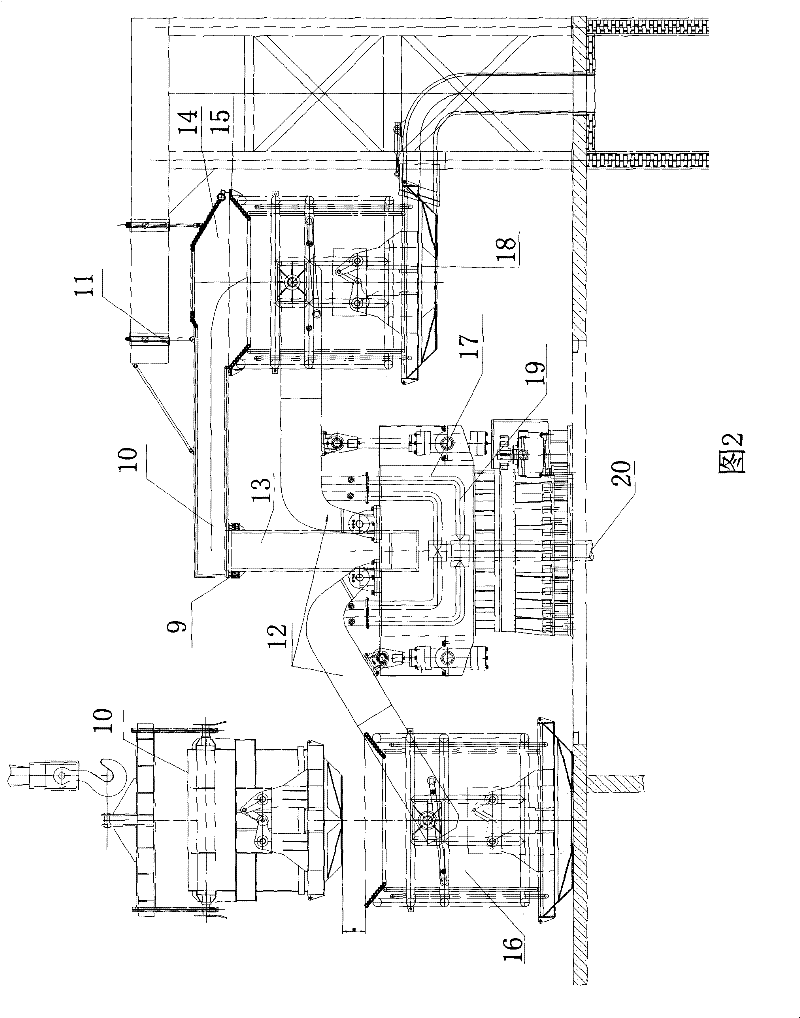

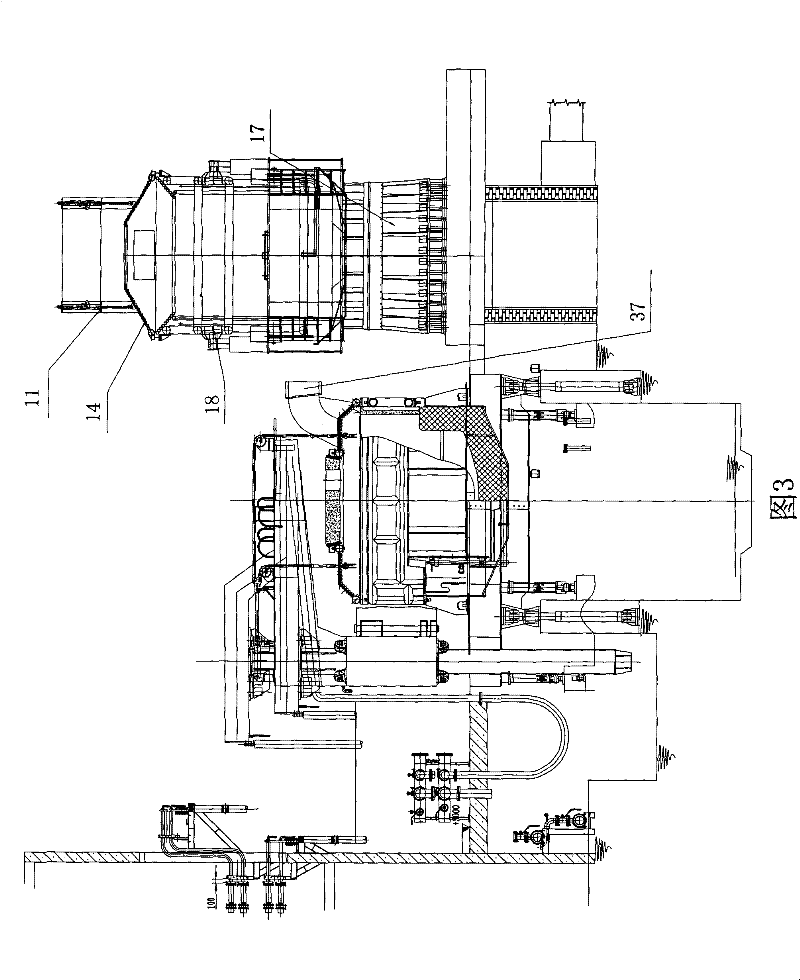

Scrap steel preheating system for electric arc furnace

ActiveCN101545724AAchieve energy savingAchieve environmental protectionPreheating chargesSteelmakingElectric arc furnace

The invention relates to a scrap steel preheating system for an electric arc furnace, which realizes the preheating for steelmaking raw materials for the electric arc furnace by fully utilizing the physical and chemical waste heat of high-temperature flue gas of the electric arc furnace and enables a dust removal system to filter and cool the high-temperature flue gas to achieve the purposes of energy saving, reduction of consumption, emission reduction and environment protection as well as improve the steelmaking production ratio of the electric arc furnace and to realize the investment and alteration of preheating scrap steel by high-temperature flue gas in a current old factory workshop. The scrap steel preheating system for an electric arc furnace comprises scrap steel preheating basket mechanisms and a basket rotation swing mechanism; the basket rotation swing mechanism is respectively connected with the scrap steel preheating basket mechanisms positioned at a scrap steel receiving position and a scrap steel preheating position through swing supporting frames; and a high-temperature flue gag water-cooling flue and a scrap steel preheating cap are arranged between the basket rotation swing mechanism and the upper end of the scrap steel preheating basket mechanism at the scrap steel preheating position.

Owner:XIAN TAOYUAN METALLURGY EQUIP ENG CO LTD

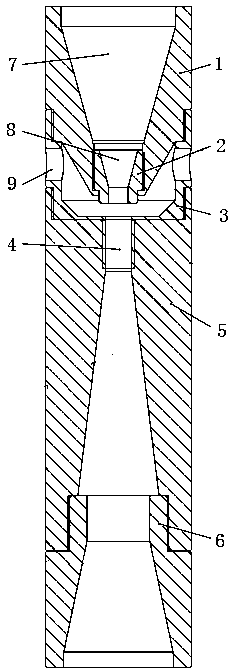

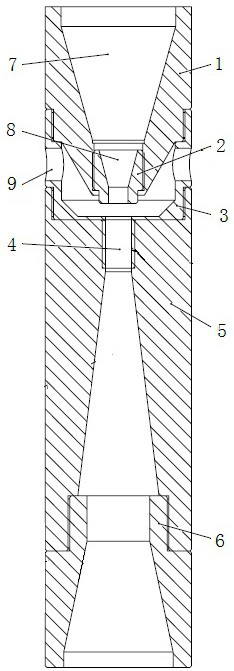

Underground self-absorption type particle jet drilling device based on Venturi effect

ActiveCN109025825AImprove stress conditionIntensive Priming and PurificationDrill bitsConstructionsSpray nozzleRock breaking

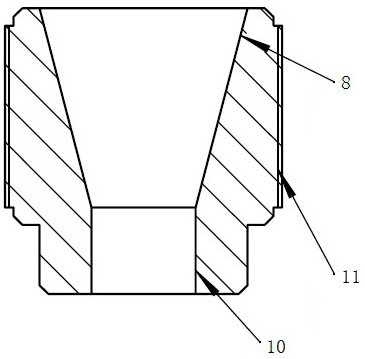

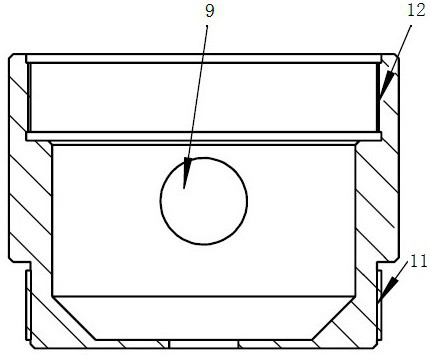

The invention relates to an underground self-absorption type particle jet drilling device based on Venturi effect, which comprises an upper joint, a nozzle, a liquid inlet chamber, a throat pipe, a diffusion pipe and a lower joint, the upper end of the liquid inlet chamber is in threaded connection with the upper joint; the inner cavity of the upper joint is composed of a horn section and a nozzlesection; the outer part of the upper joint corresponding the nozzle section is a reducing section; the nozzle section is an equal diameter section; the nozzle is in threaded connection with the nozzle section; the nozzle and the nozzle section extend into the liquid inlet chamber; the upper pore channel of the nozzle is a horn pore channel, the lower pore channel is a cylindrical pore channel, and the liquid inlet chamber is provided with a liquid inlet hole; a diffuser pipe is connected at the lower end of the liquid inlet chamber, the throat pipe is arranged at the upper end of the diffusion pipe, the nozzle is coaxial with the throat pipe, and the lower end of the diffusion pipe is connected with the lower joint. According to the invention, the rock debris sucked from an annular spacecan be used as the impact particles, the mechanical drilling speed is greatly improved, the device is suitable for deep competent formations, and the rock breaking speed can be effectively improved.

Owner:NORTHEAST GASOLINEEUM UNIV

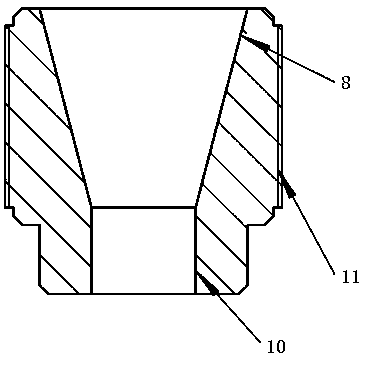

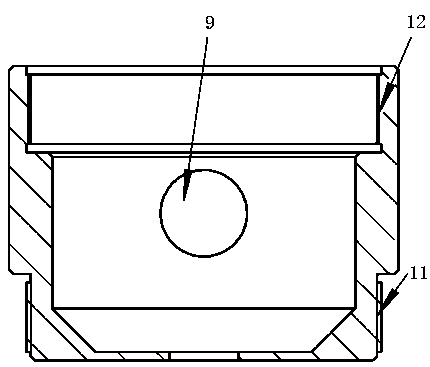

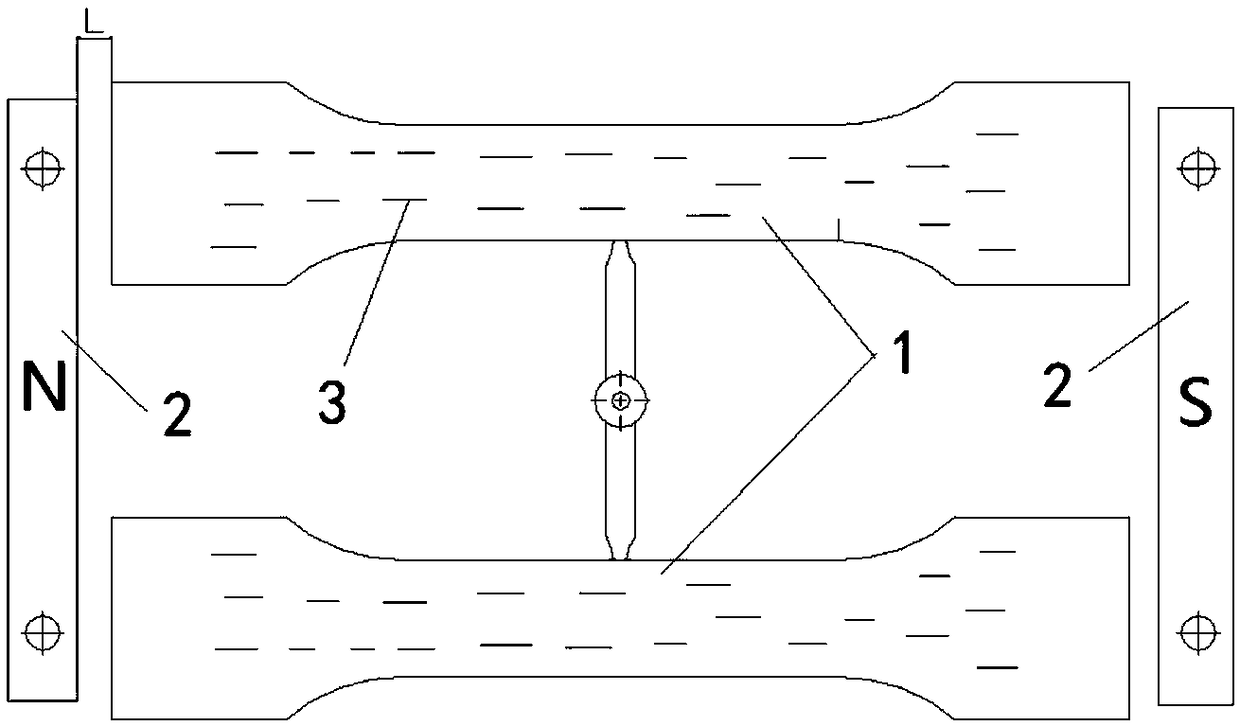

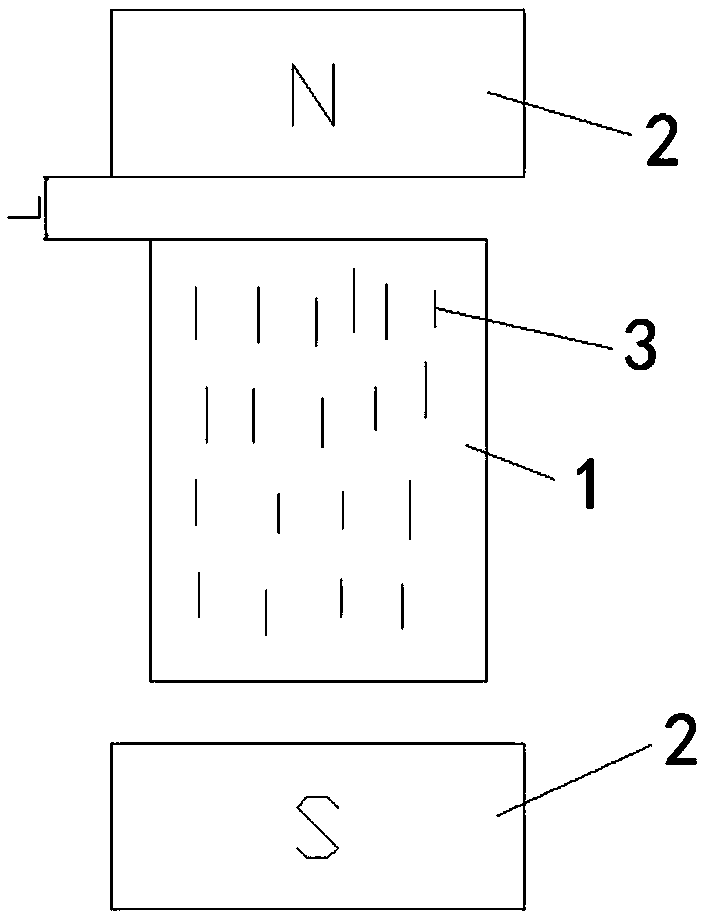

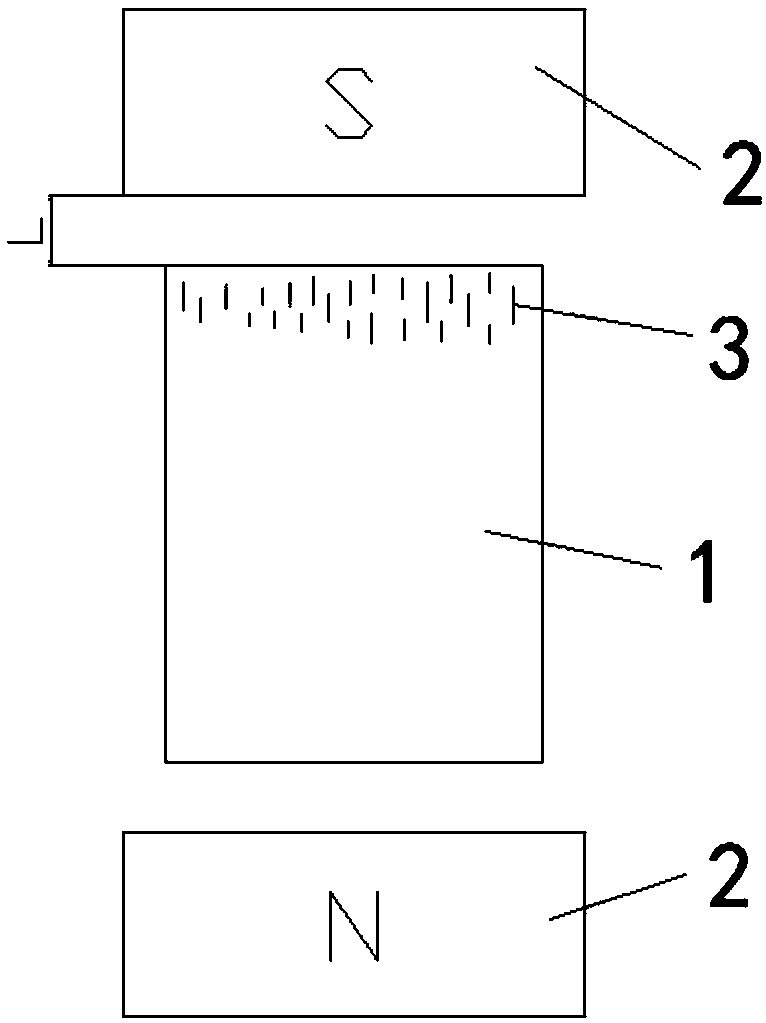

Injection molding method of glass fibers orientation in orienteering plastic part

The invention discloses an injection molding method of glass fibers orientation in an orienteering plastic part. The problems that an existing injection molding method is complex, and the glass fiberorientation is difficult to control effectively are solved. According to the technical scheme, (1) a resin-based glass fiber material, a reduced iron powder and an adhesive are uniformly mixed to prepare an injection-molded raw material; (2) the set fiber orientation is taken as a reference, permanent magnets with an N pole and an S pole are arranged on the corresponding positions of the two sidesof a mold cavity in the injection mold correspondingly; and (3) the injection-molded raw material is injected into the mold cavity of the injection mold, the fibers in the injection-molded raw material are in the set fiber orientation state under the action of a magnetic field, the injection-molded raw material in the mold cavity are synchronously heated and cured to form the plastic part, and finally, the plastic part with the set glass fiber orientation is obtained through demolding. The method is very simple, the glass fiber orientation of the surface of the plastic part and the core partglass fiber orientation can be effectively controlled, the main structure and an internal layout of an existing injection mold are not changed, the fiber content is not changed, and the parameters ofthe injection molding process are not changed.

Owner:HUBEI UNIV OF TECH

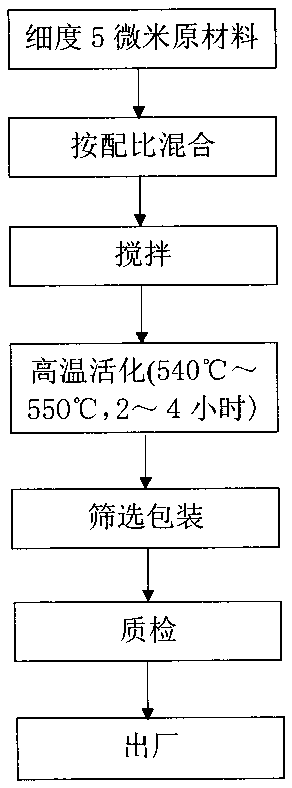

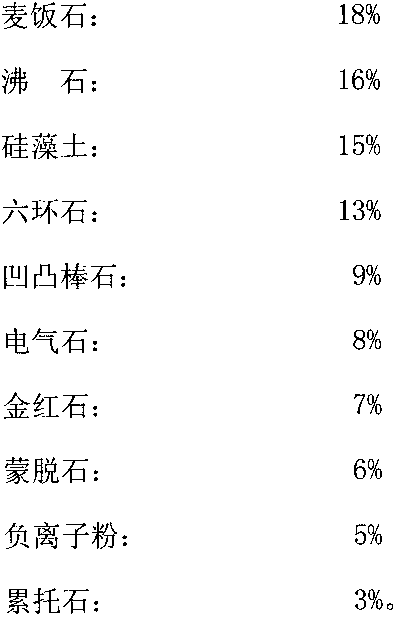

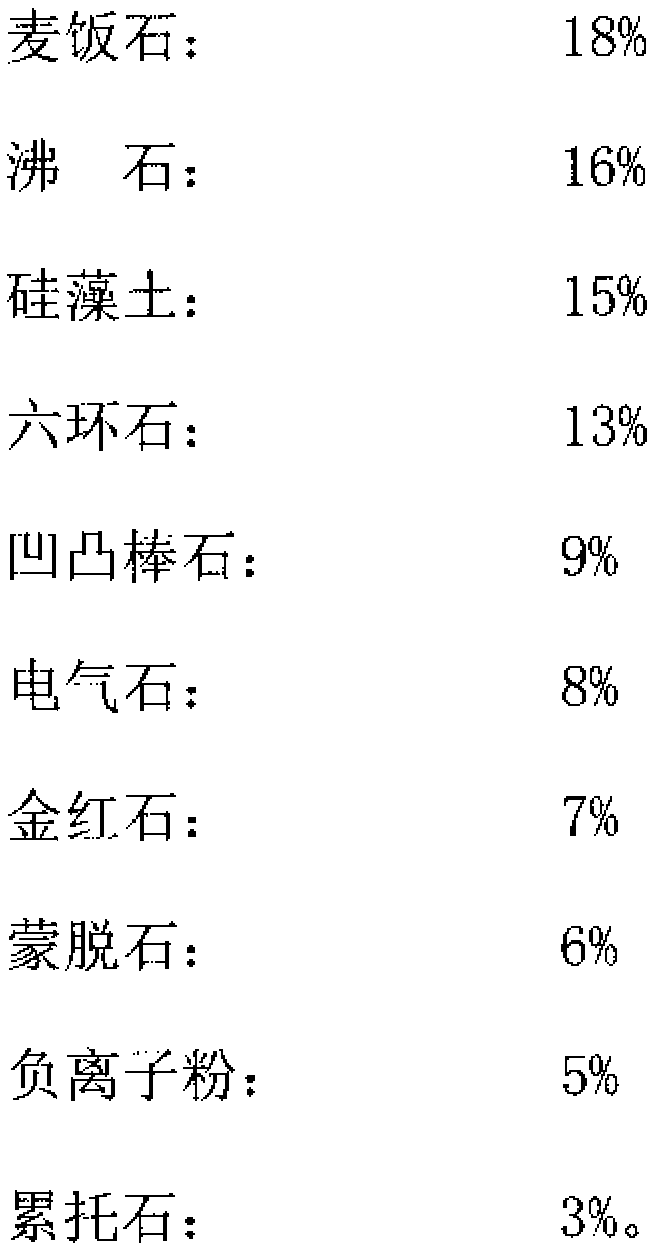

Natural mineral formaldehyde elimination agent for man-made sheet material adhesive glue

InactiveCN105505250AEradicate and eliminate releaseWell mixedNon-macromolecular adhesive additivesMontmorilloniteAdhesive glue

The present invention relates to a natural mineral formaldehyde elimination agent for man-made sheet material adhesive glues, the natural mineral formaldehyde elimination agent is prepared from 18% of 5mum medical stone, 16% of zeolite, 15% of diatomaceous earth, 13% of six-ring stone, 9% of attapulgite, 8% of tourmaline, 7% of rutile, 6% of montmorillonite, 5% of negative ion powder and 3% of rectorite by mixing, stirring, high temperature activation, cooling and screening, the natural mineral formaldehyde elimination agent is added into an adhesive glue, and the addition amount is 8 wt % to 12 wt %. The natural mineral formaldehyde elimination agent is mainly used to remove formaldehyde released by all kinds of adhesive glues used for the production of man-made sheet materials, is used for elimination of the formaldehyde from the source, and provides a green, environmentally-friendly, safe and long-term formaldehyde elimination agent for the man-made sheet material adhesive glues. In the production process no three-waste is produced, the production is clean, no secondary pollution is produced, and the purpose of purifying the air can be really achieved.

Owner:优高雅健康科技(深圳)有限公司

Preparation method of autoclaving PHC (prestressed high strength concrete) pipe pile with reduction of usage amount of cementing material

The invention discloses a preparation method of an autoclaving PHC (prestressed high strength concrete) pipe pile with reduction of usage amount of a cementing material. The preparation method comprises the following steps of (1) preparing and mixing concrete, wherein the total mass of the concrete per cubic meter is 2480kg to 2550kg, the mass of the cementing material is 420kg to 340kg, the mass ratio of water and the cementing material is 0.24 to 0.30:1, the usage amount of a water reducing agent is equal to 1.5% to 3.0% of the mass of the cementing material, the usage amount of an air entraining agent is equal to 0.005% to 0.07% of the mass of the cementing material, the balance is sand and stone, and the mass ratio of the sand and the stone is 0.32 to 0.36:1; (2) feeding the mixed concrete into a feeding machine to distribute, closing a pipe pile mould, and tensioning; (3) centrifuging the pipe pile; (4) curing by steaming; (5) demoulding the pipe pile; (6) autoclaving by steaming. The preparation method has the advantage that by mixing the air entraining agent, the usage amount of the cementing material of the autoclaving PHC pipe pile is reduced, the amount of remained grout is reduced, and the influence on strength and durability is avoided.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of autoclaving-free PHC (prestressed high strength concrete) pipe pile with reduction of usage amount of cementing material

InactiveCN104827563AReduce raw material costsImprove competitivenessCeramic shaping apparatusHigh strength concreteGrout

The invention discloses a preparation method of an autoclaving-free PHC (prestressed high strength concrete) pipe pile with reduction of usage amount of a cementing material. The preparation method comprises the following steps of (1) preparing and mixing concrete, wherein the total mass of the concrete per cubic meter is 2480kg to 2550kg, the mass of the cementing material is 450kg to 350kg, the mass ratio of water and the cementing material is 0.18 to 0.25:1, the usage amount of a water reducing agent is equal to 1.1% to 1.6% of the mass of the cementing material, the usage amount of an air entraining agent is equal to 0.005% to 0.10% of the mass of the cementing material, the balance is sand and stone, the mass ratio of the sand and the stone is 0.32 to 0.36:1, and the cementing material comprises cement and mineral mixtures; (2) feeding the mixed concrete into a feeding machine to distribute, closing a pipe pile mould, and tensioning; (3) centrifuging the pipe pile; (4) curing by steaming; (5) demoulding the pipe pile. The preparation method has the advantage that by mixing the air entraining agent, the usage amount of the cementing material of the autoclaving-free PHC pipe pile is reduced, the amount of remained grout is reduced, and the influence on strength and durability is avoided.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous adhesive for rubber tube, and preparation method thereof

InactiveCN102786894ANo pollution in the processJob safetyLayered productsCarboxyl rubber adhesivesVulcanizationPolymer science

The invention discloses an aqueous adhesive for a rubber tube, and a preparation method thereof. In the existing rubber tube industry, adhesives have high toxicity, environmental pollution is generated, fire disaster is easily caused, an operation process is danger, and bond strength is not high. A purpose of the present invention is to solve problems in the existing rubber tube industry. The aqueous adhesive of the present invention comprises the following components, by weight, 10-80% of carboxylic butadiene-styrene latex, 8-30% of a tackifier, 5-40% of a filler, 5-20% of a thickening agent, 0.1-2% of an anti-aging agent, 0.5-2% of a vulcanization agent, 0.1-0.5% of a vulcanization accelerator, 0.1-1.5% of a wetting agent, and 10-80% of water. The aqueous adhesive and the preparation method in the present invention have the following advantages that: characteristics of no toxicity, no harm and no environment pollution are provided, an operation process is safe, fire disaster is not easily caused, bonding strength is high, heat resistance is excellent, ageing resistance is good, a storage time is long, the original process is not changed during the production process, and the aqueous adhesive and the preparation method can be widely used in rubber tube industry.

Owner:张晓龙 +1

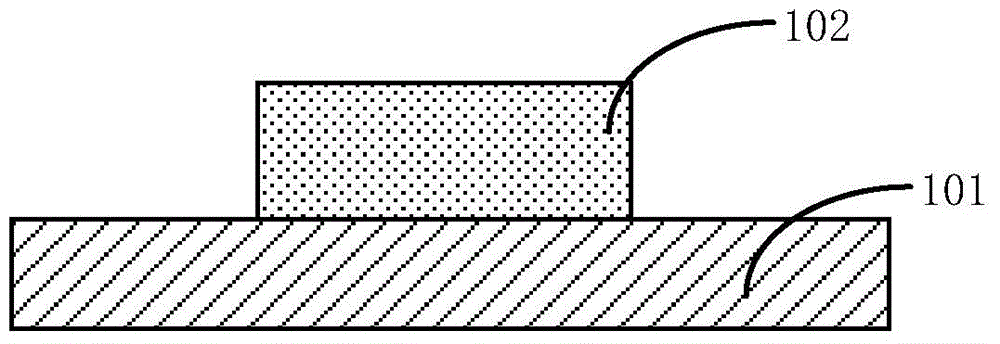

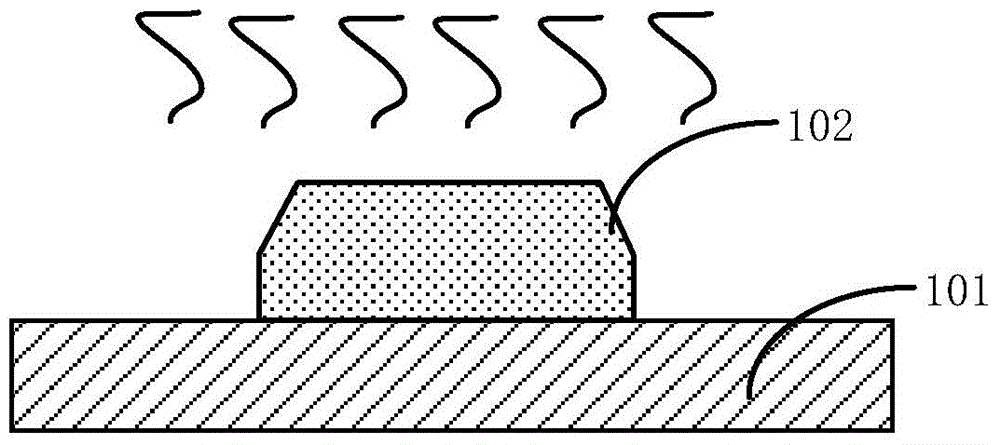

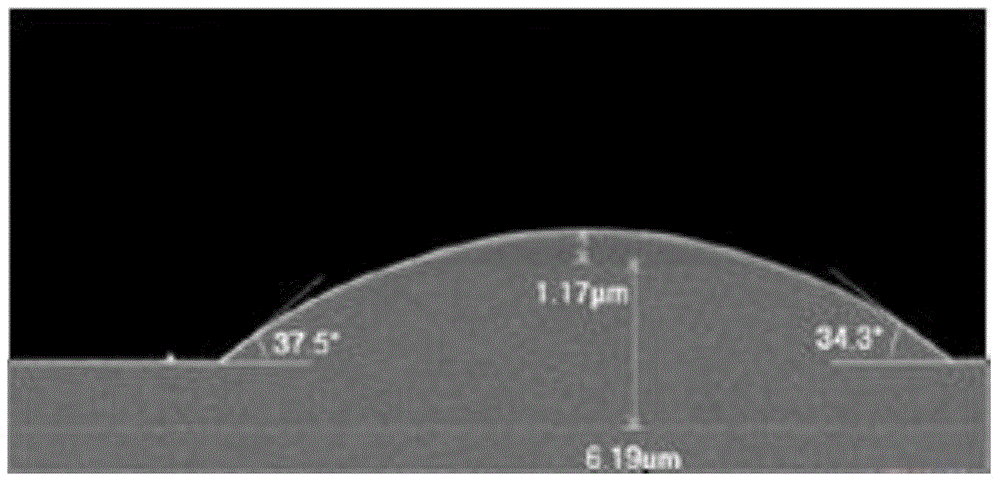

MEMS device, preparation method and electronic apparatus

ActiveCN105584985ASolve the problem that the photoresist morphology formed by the reflow process cannot be precisely controlledChange processSemi-permeable membranesFixed microstructural devicesLength wavePhotoresist

The invention relates to a MEMS device, a preparation method and an electronic apparatus. The method comprises the following steps: S1) providing a MEMS wafer, forming a first photoresist layer capable of sensitizing a first wavelength light source on the MEMS wafer; S2) forming a second photoresist layer capable of sensitizing a second wavelength light source on the first photoresist layer for covering the first photoresist layer; S3) selecting the first wavelength light source for exposing the first photoresist layer, selecting the second wavelength light source for exposing the second photoresist layer; and S4) developing the first photoresist layer and the second photoresist layer for forming a first pattern in the first photoresist layer, forming a second pattern in the second photoresist layer, wherein the size of the second pattern is larger than that of the first pattern; and S5) performing heating backflow on the first pattern and the second pattern. The problem of difficult accurate control of photoresist morphology formed by the backflow technology can be solved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

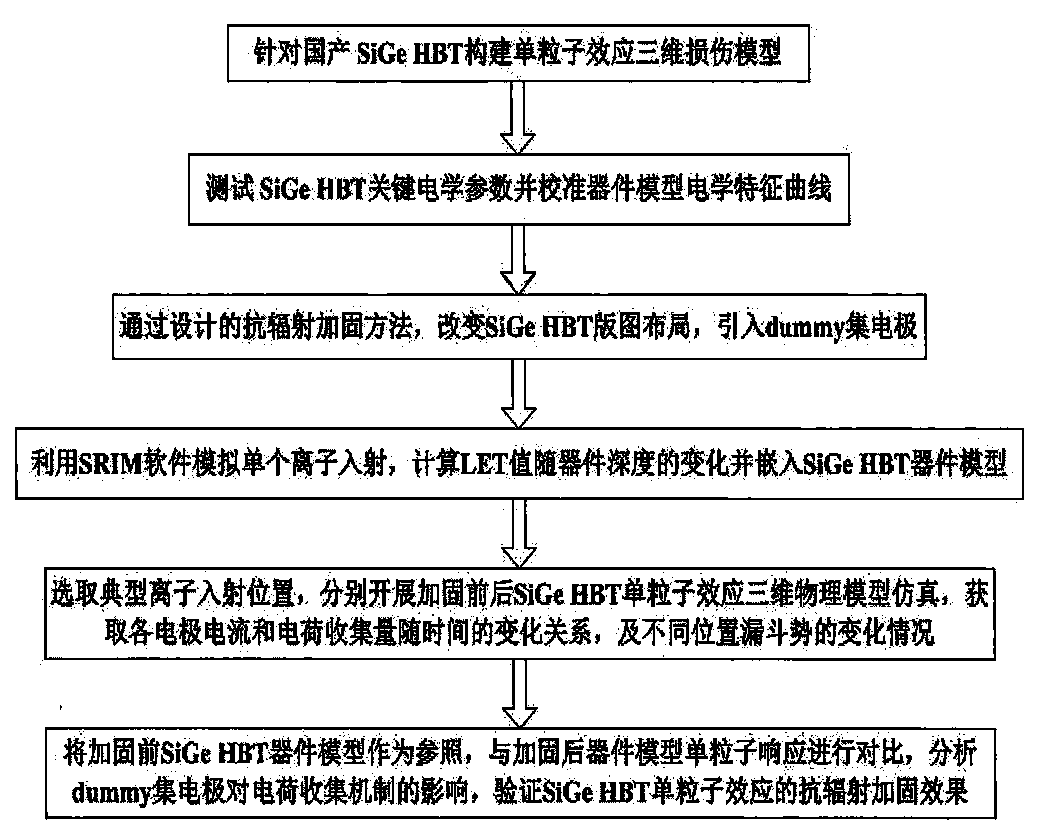

Germanium-silicon heterojunction bipolar transistor single event effect resisting strengthening method based on simulation

InactiveCN104133974AAvoid stressful, experimentally expensive problemsGuaranteed accuracySemiconductor/solid-state device testing/measurementSpecial data processing applicationsSingle ionSilicon heterojunction

The invention relates to a germanium-silicon heterojunction bipolar transistor single event effect resisting strengthening method based on simulation. The method comprises the steps that a three-dimensional damage model is built, key electrical parameters of the model are calibrated, through the designed radiation resisting strengthening method, a device collector-substrate junction is extended, a fake collector is introduced, a single ion incident device is simulated through SRIM software, the change of a linear energy transmission value along with the device depth is obtained, a linear energy transmission value file is compiled, a device model is embedded, the typical incident position of ions is selected, single event effect simulation of a strengthened device model and single event effect simulation of a non-strengthened device model are carried out respectively, the device model obtained before strengthening is adopted as the reference and is compared with the single event response of the strengthened device model, and the radiation resisting strengthening effect of a germanium-silicon heterojunction bipolar transistor is verified. According to the method, the problems that a ground simulation test cost is high and the machine hour is tense are solved; the single event effect resisting capacity of the germanium-silicon heterojunction bipolar transistor is effectively improved, and meanwhile the defects that the process experiment cost is high and the period is long are overcome.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

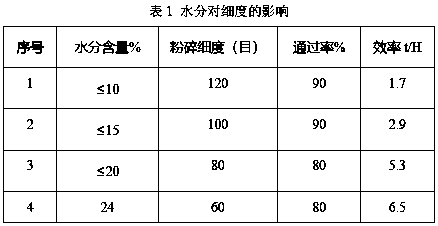

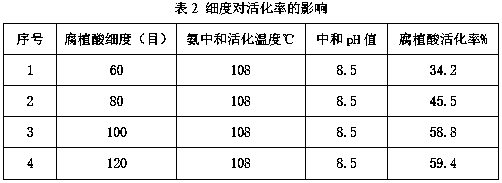

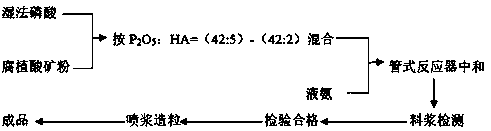

Humic-acid-containing diammonium phosphate neutralization and activation one-step production technology

ActiveCN109665926AWide variety of sourcesLow priceAmmonium salt fertilisersOrganic fertilisersPhosphoric acidSlurry

The invention discloses a humic-acid-containing diammonium phosphate neutralization and activation one-step production technology which particularly includes the steps: (1) primarily crushing and drying weathered coal and brown coal and then secondarily crushing the coal to obtain humic acid mineral powder (HA); (2) mixing and dispersing wet-process phosphoric acid and the humic acid mineral powder, pumping the wet-process phosphoric acid and the humic acid mineral powder to a tubular reactor, neutralizing and concentrating the wet-process phosphoric acid, the humic acid mineral powder and ammonia gas formed after liquid ammonia gasification, and then performing slurry-spraying granulation to obtain humic-acid-containing diammonium phosphate. The production technology can be directly implemented on an original production line without changing the technology or changing overall technological process, an adding method is simple and uniform, products are controllable, investment is less,the production process is clean, and the problem of blockage of a tubular reactor in a traditional technology is solved. The batching proportion of the humic acid mineral powder and the wet-process phosphoric acid can be adjusted, and the technology controllable products are uniform and stable. The humic acid content of the produced products can reach 1-3%, plant growths can be effectively stimulated, and agricultural sustainable development is facilitated.

Owner:LIAONING SHUNYI AGRI TECH CO LTD

Shadow mask type plasma display board

InactiveCN101369507AImprove luminous brightnessImprove luminous efficiencySolid cathode detailsCold-cathode tubesTectorial membraneUltraviolet lights

The invention relates to a plasma display panel, especially a shadow mask type plasma display panel. The invention comprises a front base plate, a back base plate, a shadow mask, in which, the shadow mask is packaged between the front base plate and the rear base plate and is a conducting plate comprising a face hole array and a bottom hole array, the face hole and the bottom hole belong to an upper surface and a lower surface of the same discharge unit, a fluorescent powder layer is coated on the inner wall of the face hole so that the space corresponding to the face hole in the discharge basic unit is a visible light luminous area, the invention is characterized in that, a layer of diffuse reflection film is prepared on the protecting film surface of the rear base plate for absorbing less deep ultraviolet light, the visible light reflected on the surface of the rear base plate by the bottom hole in the face hole space is reflected in the face hole, a part of the visible light sends to the front base plate for receiving by human eye. The invention realizes the purposes of improving brightness and luminous efficiency.

Owner:SOUTHEAST UNIV

A liquid crystal phase shifter unit for reflective adjustable phase shifter

The invention discloses a liquid crystal phase shift unit for a reflected adjustable phase shifter. The liquid crystal phase shift unit comprises two upper and lower layers of medium substrates, a liquid crystal layer is injected in the gap between the two upper and lower layers of medium substrates, a metal microstrip patch electrode is arranged on the lower side of the upper layer medium substrate, a metal total reflection ground electrode is arranged on the upper side of the lower layer medium substrate, and polyimide film coating is respectively arranged on upper and lower surfaces of the liquid crystal layer; the metal microstrip patch electrode comprises two identical dipole patches, an offset voltage loading line and an auxiliary electrode, the two dipole patches are arranged in parallel, the offset voltage loading line is connected with the two dipole patches orthogonally to form a patch unit, the auxiliary electrode is a quadrilateral metal frame, and the quadrilateral metal frame surrounds the whole patch unit and is connected with the offset voltage loading line. The auxiliary electrode has a simple main body structure, educes the saturation bias voltage, and can be used in the field of liquid crystal reflected phase shifters and phase control antennas within microwave, millimeter wave and terahertz frequency bands.

Owner:HEFEI UNIV OF TECH

Preparation method of centrifugal concrete water supply-drainage pipe capable of reducing using amount of binding material

InactiveCN104803637AReduce dosageLow costCeramic shaping apparatusCentrifugationStructural engineering

The invention discloses a preparation method of a centrifugal concrete water supply-drainage pipe capable of reducing the using amount of a binding material. The preparation method comprises the following steps: (1) preparing and stirring concrete, wherein the total mass of the concrete in every cubic meter is 2380 to 2450 kg, the mass of the binding material is 340 to 375 kg, the mass ratio of water to the binding material is (0.40-0.45):1, the using amount of a water reducing agent is 0.8% to 1.2% of the mass of the binding material, the using amount of an air entraining agent is 0.005% to 0.04% of the mass of the binding material, the balance comprises sand and stone, and the mass ratio of the sand to the stone is (0.32-0.36):1; (2) feeding the stirred concrete to a feeding machine for material distribution, and carrying out mold assembling; (3) carrying out pipeline centrifugation; (4) carrying out steam curing; (5) carrying out pipeline demolding. According to the preparation method, through the addition of the air entraining agent, the using amount of the pipeline binding material is reduced, the amount of residual slurry is reduced, and the influence on strength and durability is avoided.

Owner:SOUTH CHINA UNIV OF TECH

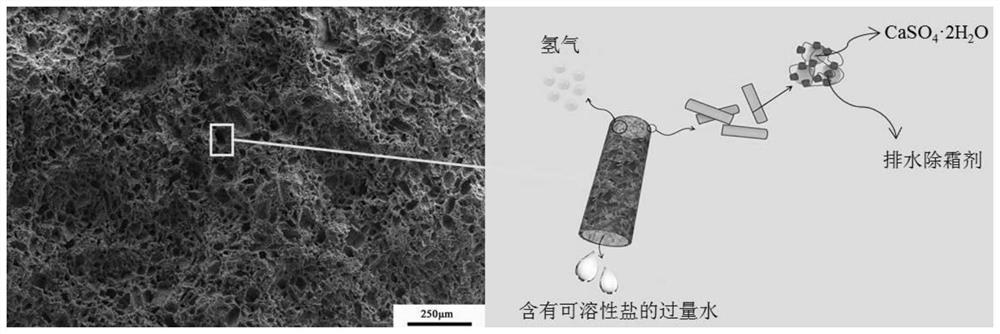

Gypsum product drainage defrosting agent and preparation method thereof

ActiveCN114315193AVisible pan-cream effectReduce dosageSolid waste managementEngineeringDimethyl siloxane

The invention relates to a drainage defrosting agent for a gypsum product, which is prepared by mixing hydrogen-containing silicone oil, dimethyl silicone oil, 1, 1, 3, 3-tetramethyldisiloxane, 1, 1, 5, 5-tetramethyl-3, 3-diphenyl trisiloxane, dimethyl hydroxyl silicone oil, hydrogen-terminated phenyl silicone oil and hydrogen-terminated polydimethylsiloxane. The gypsum product can discharge water to achieve the defrosting effect, and has the advantages of being good in dispersity, convenient and simple to prepare and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

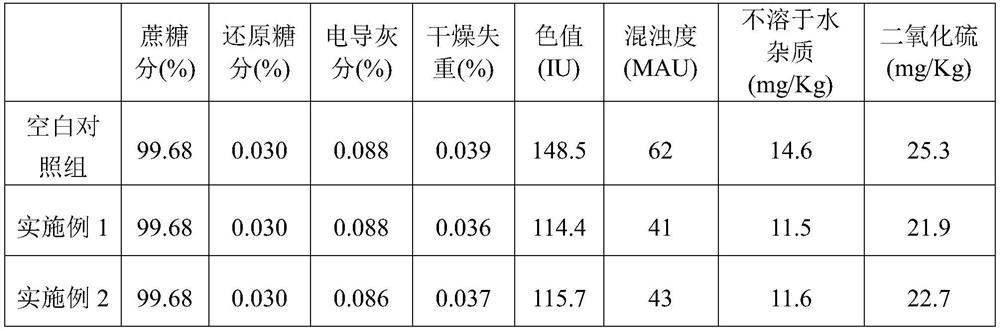

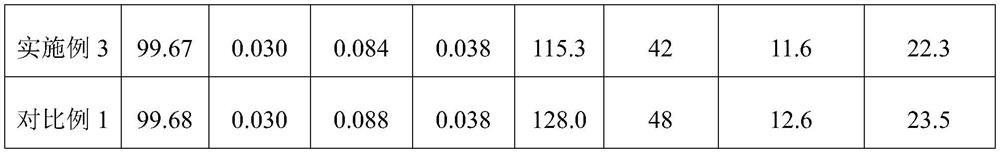

Special compound enzyme preparation for sugar production and preparation method and application of special compound enzyme preparation

ActiveCN112048496ALow viscosityAids in absorbencyOxidoreductasesGlycosylasesPectinaseOxidative enzyme

The invention relates to the technical field of cane sugar making clarification, and particularly discloses a special compound enzyme preparation for sugar production. The special compound enzyme preparation comprises the following components in percentage by weight: 40-48% of dextranase, 18-25% of pectinase, 8-12% of cellulase, 4-6% of polyphenol oxidase, 4-6% of papain, 8-12% of magnesium chloride and 3-6% of poly dimethyl diallyl ammonium chloride. The invention also provides a preparation method of the special compound enzyme preparation for sugar production. A complex enzyme preparation is added to sugarcane squeezed juice for clarification treatment, the viscosity of sugar juice is obviously reduced, a certain viscosity reducing effect is achieved in the sugar boiling process, absorption and crystallization of sucrose molecules are facilitated, the color value of a finished product is reduced by 20-30%, the turbidity is reduced by 30% or above, water-insoluble impurities are reduced by 20-30%, the simple purity is improved, the sucrose recovery rate is increased, and waste molasses yield can be reduced.

Owner:南宁雄晋生物科技有限公司

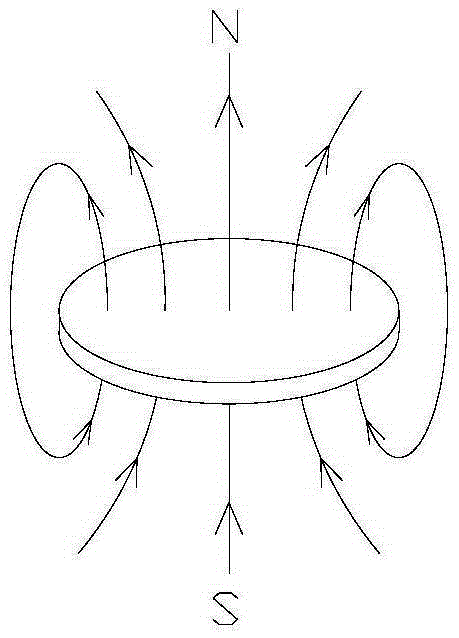

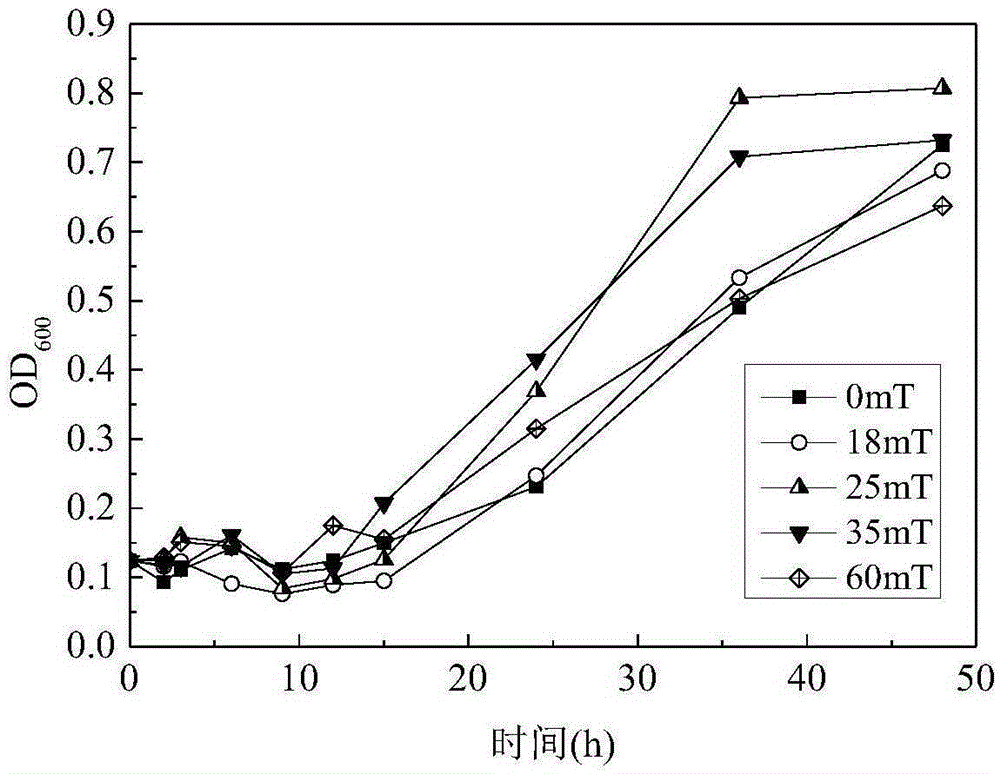

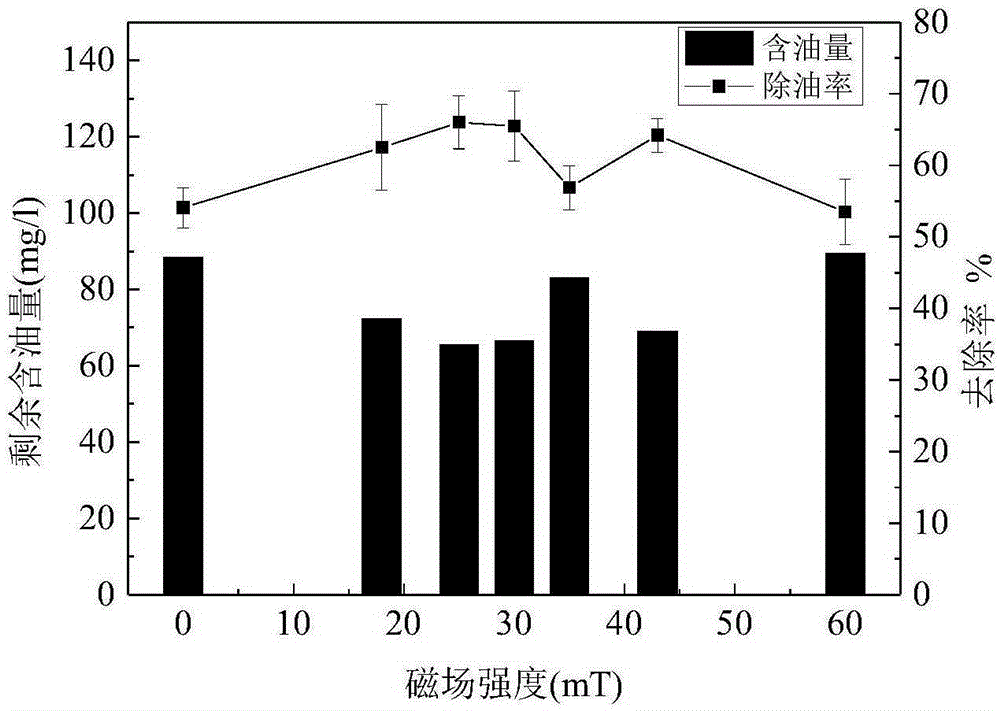

Method for improving oil removing efficiency of oil removing bacteria

ActiveCN105254025APromote growthImprove adaptabilityBacteriaMicroorganism based processesSewageSewage treatment

The invention aims to provide a method for improving oil removing efficiency of oil removing bacteria. According to the microorganism oil removing method, a magnetic field is additionally arranged around the oil removing bacteria, in the mode of adjusting the intensity and action of the magnetic field, the degrading effect on petroleum and the capacity for resisting impact loads of the oil removing bacteria can be effectively improved, process operation stability is improved, and the method belongs to the field of biological treatment on oily sewage. An adopted permanent magnet is a round ferrite permanent magnet, according to the action condition, the magnetic field intensity is 18-35 mT, and the magnetic action is continuous. The magnetic field is generated by the commercially available permanent magnet, the needed magnetic field intensity is low, electric energy consumption is not needed, investment is low, the effect is good, an existing process flow path is not changed, arrangement of large equipment is avoided, and the enhanced oily sewage treatment technology is suitable for the situation of China, economical and feasible.

Owner:HARBIN ENG UNIV

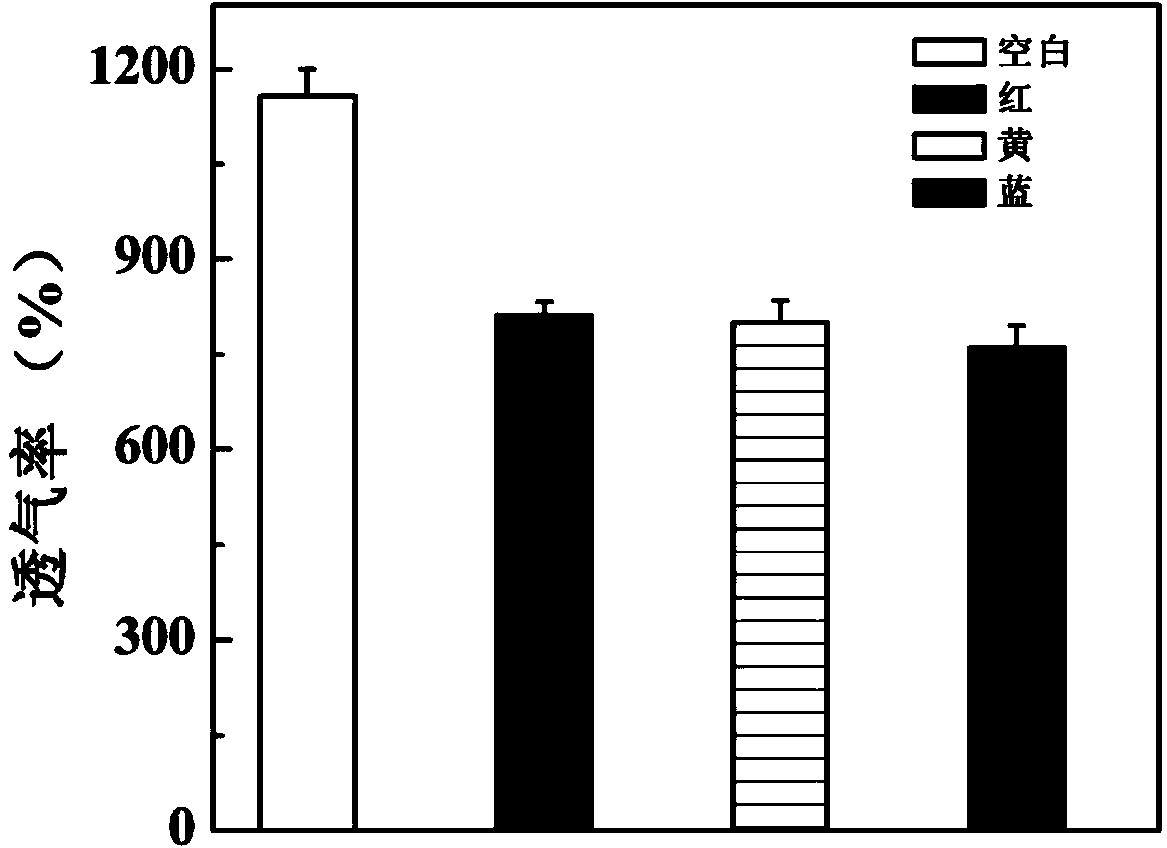

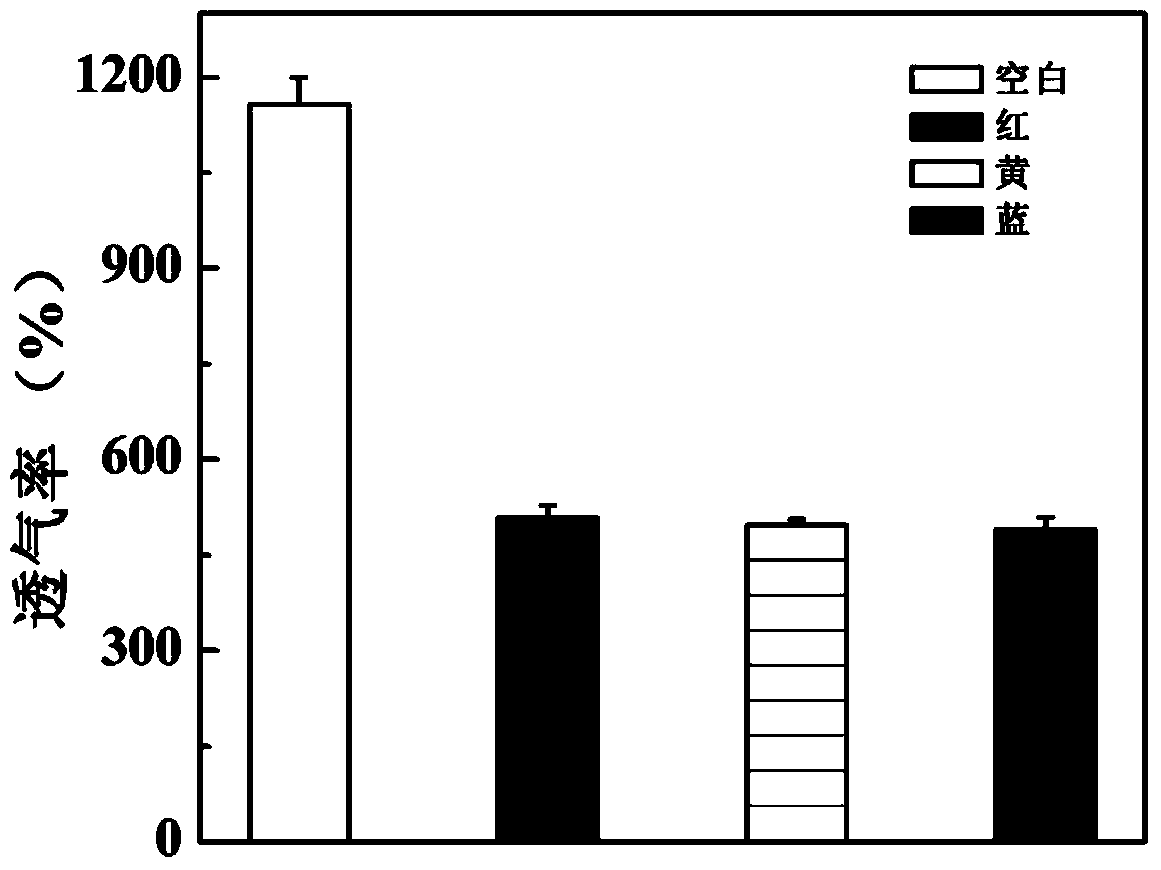

Dyeing method of polypropylene non-woven fabric material

The invention relates to a dyeing method of a polypropylene non-woven fabric material. The method comprises the following steps: dispersing dye in water; adding a self-cross-linking adhesive, and emulsifying to obtain a dispersed dye system containing the adhesive; then treating a polypropylene non-woven fabric by using a soaking or padding method, and drying the polypropylene non-woven fabric, wherein the dye accounts for 0.25-1 mass percent of the dispersed dye system, and the self-cross-linking adhesive accounts for 15-20 mass percent of the dispersed dye system. The production process flow of the non-woven fabric is not changed, the non-woven fabric carries different colors, and the method plays an important role in business application of the non-woven fabric; used raw materials are low in cost, are easily obtained, and are economical and environmentally friendly; toxic or side effects on a human body are avoided; the used method is quick, simple, convenient, efficient, low in cost and convenient to operate.

Owner:DONGHUA UNIV +1

Scrap steel preheating system for electric arc furnace

ActiveCN101545724BImprove productivityAvoid disadvantagesPreheating chargesSteelmakingElectric arc furnace

The invention relates to a scrap steel preheating system for an electric arc furnace, which realizes the preheating for steelmaking raw materials for the electric arc furnace by fully utilizing the physical and chemical waste heat of high-temperature flue gas of the electric arc furnace and enables a dust removal system to filter and cool the high-temperature flue gas to achieve the purposes of energy saving, reduction of consumption, emission reduction and environment protection as well as improve the steelmaking production ratio of the electric arc furnace and to realize the investment and alteration of preheating scrap steel by high-temperature flue gas in a current old factory workshop. The scrap steel preheating system for an electric arc furnace comprises scrap steel preheating basket mechanisms and a basket rotation swing mechanism; the basket rotation swing mechanism is respectively connected with the scrap steel preheating basket mechanisms positioned at a scrap steel receiving position and a scrap steel preheating position through swing supporting frames; and a high-temperature flue gag water-cooling flue and a scrap steel preheating cap are arranged between the basket rotation swing mechanism and the upper end of the scrap steel preheating basket mechanism at the scrap steel preheating position.

Owner:XIAN TAOYUAN METALLURGY EQUIP ENG CO LTD

Preparation method of PC (prestressed concrete) pipe pile with reduction of usage amount of cementing material

InactiveCN104827564AReduce dosageLow costCeramic shaping apparatusPrestressed concreteUltimate tensile strength

The invention discloses a preparation method of a PC (prestressed concrete) pipe pile with reduction of usage amount of a cementing material. The preparation method comprises the following steps of (1) preparing and mixing concrete, wherein the total mass of the concrete per cubic meter is 2450kg to 2520kg, the mass of the cementing material is 320kg to 420kg, the mass ratio of water and the cementing material is 0.28 to 0.32:1, the usage amount of a water reducing agent is equal to 1.2% to 2.0% of the mass of the cementing material, the usage amount of an air entraining agent is equal to 0.005% to 0.08% of the mass of the cementing material, the balance is sand and stone, and the mass ratio of the sand and the stone is 0.32 to 0.36:1; (2) feeding the mixed concrete into a feeding machine to distribute, closing a pipe pile mould, and tensioning; (3) centrifuging the pipe pile; (4) curing by steaming; (5) demoulding the pipe pile; (6) curing by autoclaving. The preparation method has the advantages that by mixing the air entraining agent, the usage amount of the cementing material of the PC pipe pile is reduced, the amount of remained grout is reduced, and the influence on strength and durability is avoided.

Owner:SOUTH CHINA UNIV OF TECH

Downhole self-priming particle jet drilling device based on Venturi effect

ActiveCN109025825BSpeed up the boot processImprove purification effectDrill bitsConstructionsUpper jointWell drilling

The invention relates to a downhole self-priming particle jet drilling device based on the Venturi effect. The lower joint, the upper end of the liquid inlet chamber is threadedly connected with the upper joint, the inner cavity of the upper joint is composed of a horn section and a nozzle section, the outer part of the upper joint corresponding to the nozzle section is a reduced diameter section, the nozzle section is an equal diameter section, and the nozzle and the nozzle section are threadedly connected , the nozzle and the nozzle section extend into the liquid inlet chamber, the upper channel of the nozzle is a horn channel, the lower channel is a cylindrical channel, and the liquid inlet chamber has a liquid inlet hole; The throat pipe is arranged on a coaxial line, and the lower end of the diffusion pipe is connected with the lower joint. The invention can take the cuttings sucked from the annular space as impact particles, greatly improve the mechanical drilling speed, is suitable for the deep hard formation, and can effectively improve the rock breaking speed.

Owner:NORTHEAST GASOLINEEUM UNIV

Printing and dyeing method of polypropylene non-woven fabric material

The invention relates to a printing and dyeing method of a polypropylene non-woven fabric material. The method comprises the following steps: dispersing dye in water; adding a self-cross-linking adhesive, and emulsifying to obtain dispersed dye color paste containing the adhesive; adding a thickener to obtain dispersed dye printing gum; printing and drying a polypropylene non-woven fabric, wherein the dye accounts for 0.25-1 mass percent of the dispersed dye color paste, the self-cross-linking adhesive accounts for 15-20 mass percent of the dispersed dye color paste, the thickener accounts for 1-2 mass percent of the dispersed dye color paste, and the balance is water. The method is simple, and low in cost. The treated non-woven fabric does not need to be washed by water, and is great in application prospect.

Owner:DONGHUA UNIV +1

A preparation method of pc pipe piles reducing the amount of cementitious materials

InactiveCN104827564BReduce dosageLow costCeramic shaping apparatusPrestressed concreteUltimate tensile strength

The invention discloses a preparation method of a PC (prestressed concrete) pipe pile with reduction of usage amount of a cementing material. The preparation method comprises the following steps of (1) preparing and mixing concrete, wherein the total mass of the concrete per cubic meter is 2450kg to 2520kg, the mass of the cementing material is 320kg to 420kg, the mass ratio of water and the cementing material is 0.28 to 0.32:1, the usage amount of a water reducing agent is equal to 1.2% to 2.0% of the mass of the cementing material, the usage amount of an air entraining agent is equal to 0.005% to 0.08% of the mass of the cementing material, the balance is sand and stone, and the mass ratio of the sand and the stone is 0.32 to 0.36:1; (2) feeding the mixed concrete into a feeding machine to distribute, closing a pipe pile mould, and tensioning; (3) centrifuging the pipe pile; (4) curing by steaming; (5) demoulding the pipe pile; (6) curing by autoclaving. The preparation method has the advantages that by mixing the air entraining agent, the usage amount of the cementing material of the PC pipe pile is reduced, the amount of remained grout is reduced, and the influence on strength and durability is avoided.

Owner:SOUTH CHINA UNIV OF TECH

Method for desiliconizing sodium aluminate solution

InactiveCN105600811AImprove performanceEfficient use ofAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlagCarbide

The invention provides a method for desiliconizing a sodium aluminate solution. The method comprises the following steps: adding carbide slag into the sodium aluminate solution to carry out desiliconization treatment to obtain a desiliconized sodium aluminate solution, wherein the mass content of Ca(OH)2 in the carbide slag is not less than 65 percent, the content of available calcium is more than 55 percent, and the grain size of the carbide slag is less than 150mu m. According to the method, the carbide slag is used as a desiliconizing raw material, recycling and environmental friendliness of waste materials can be realized, the desiliconization cost can be reduced, and the silicon index of the desiliconized sodium aluminate solution is more than or equal to 700.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Ultrafine Grain WC-CO Cemented Carbide Containing Rare Earth Elements

ActiveCN101760685BNo change to the process flowSteady improvement in overall performanceRare-earth elementMischmetal

The invention discloses an ultra-fine-grained WC-Co hard alloy containing rare earth elements and a preparation method thereof, which belong to the technical field of hard alloy preparation. The weight of the WC hard phase in the cemented carbide accounts for 85-94% of the cemented carbide, the weight of the Co binder phase accounts for 5-14% of the cemented carbide, and the weight of the grain growth inhibitor accounts for 0.3-94% of the cemented carbide. 2.0%, the weight of the rare earth metal element in the rare earth additive accounts for 0.2-1.2% of the Co binding phase. Weigh various powder raw materials, ball mill, dry, and granulate to form a mixture; press the mixture to form, sinter, and cool to obtain cemented carbide. The rare earth addition method of nanoscale rare earth oxide or Co-RE composite powder is simple and easy, and the distribution of rare earth is uniform and conducive to the physical and chemical reactions in the alloy sintering process; the production cost is low; the performance of the alloy is stable and improved, and it is easy to implement and produce application.

Owner:GRIMAT ENG INST CO LTD

Acidic etching solution recovery method

InactiveCN112376049AReliable technologyEasy to operatePhotography auxillary processesProcess efficiency improvementSolution treatmentElectrolysis

The invention discloses an acidic etching solution recovery method. The acidic etching solution recovery method comprises the following steps that an acidic etching waste solution is pretreated, and the pH value of the acidic etching waste solution is regulated to be in an alkaline range; the acidic etching waste solution is extracted by using a solvent to obtain a loaded copper oil phase and a first water phase; secondary extraction is carried out on the loaded copper oil phase to obtain a second oil phase and a second water phase; a copper extraction agent is added into the second oil phaseto obtain a loaded copper extraction solution; the second water phase is electrolyzed, copper ions in the second water phase are deposited, and electrodeposited liquid and deposited copper are obtained; and the pH value of the first water phase is adjusted to be neutral, and then an alkaline solution is formed by adopting a membrane treatment fine adjustment or reduced pressure distillation process. The acidic etching solution recovery method has the advantages that the technological process and the management program of a printed circuit board factory are not changed, only the waste solutionneeds to be discharged into an acidic etching solution treatment and recovery system, the whole process is continuously and automatically performed, the technological content of equipment is high, andcondensation utilization and zero emission are achieved.

Owner:江苏净拓环保科技有限公司

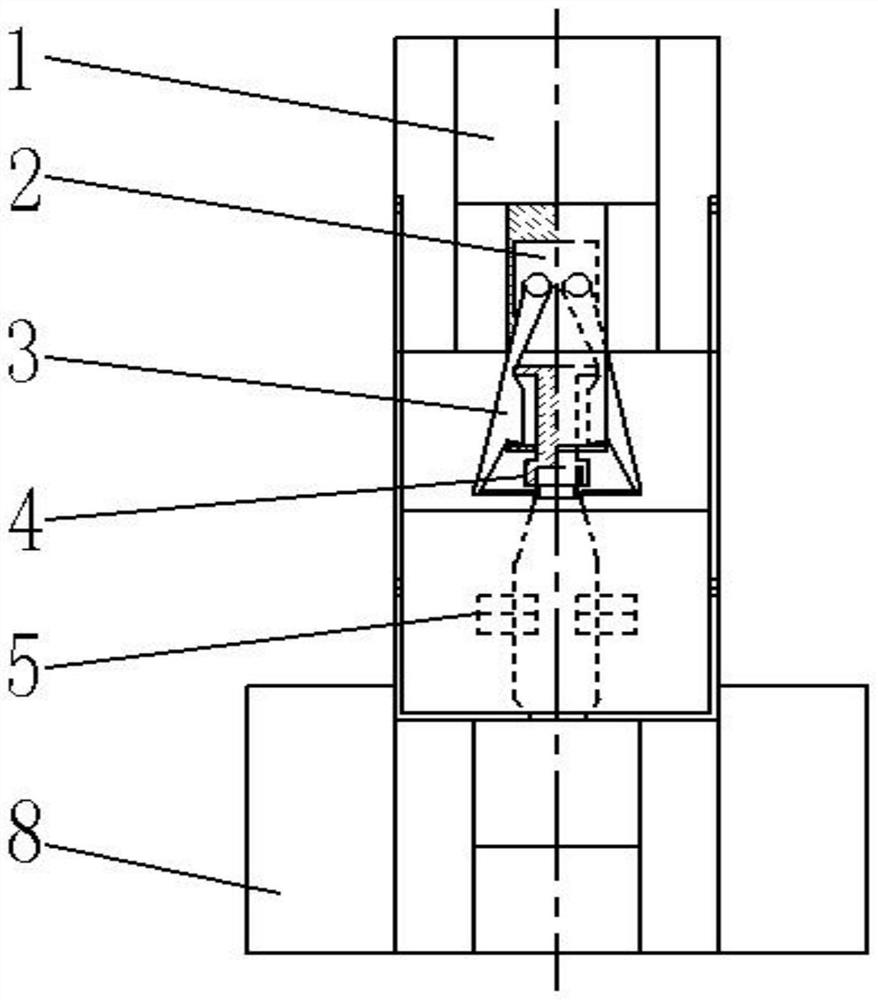

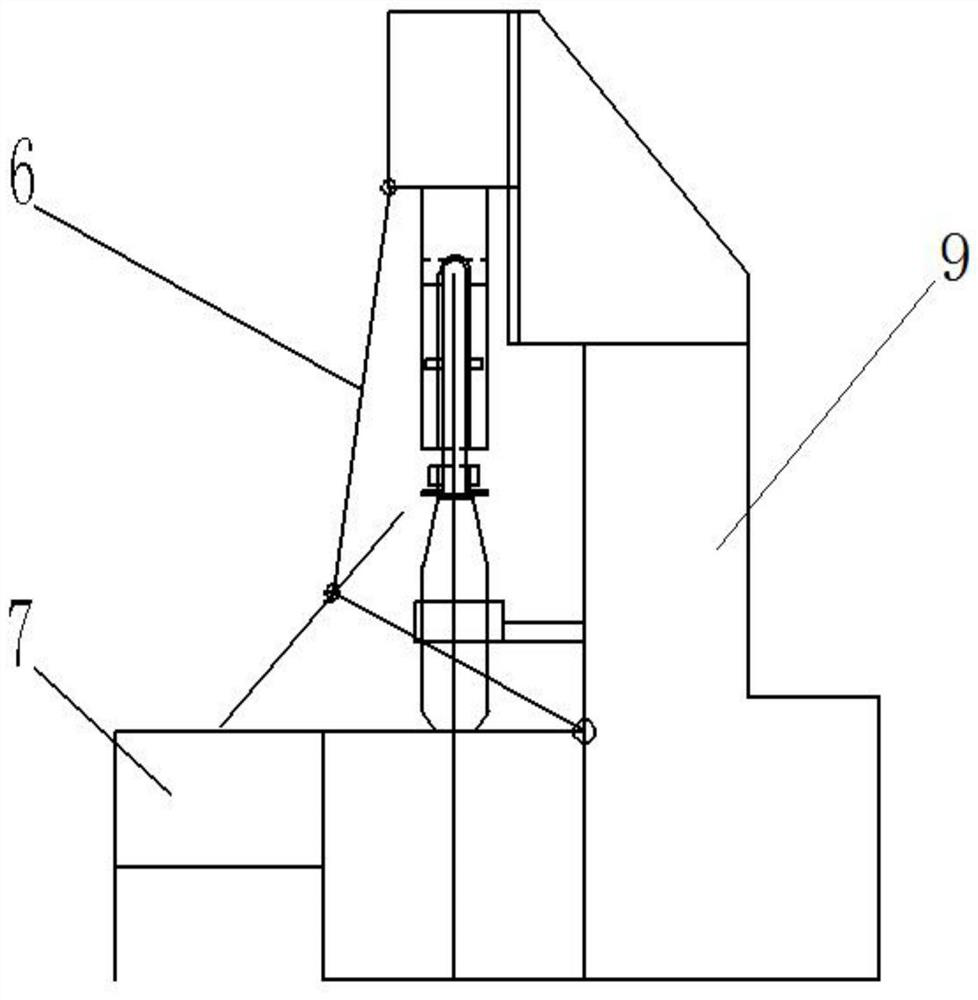

Equipment for disassembling threaded part

The invention provides equipment for disassembling a threaded part, and aims to solve the problems that the disassembling efficiency of an elastic opening threaded protective sleeve is too low and potential safety hazards of an automatic production line are solved. Equipment for disassembling threaded parts comprises a movable platform, a main shaft (2), a clamping mechanism (3), a socket spanner (4), a mechanical arm (5), a collecting mechanism (6), a collecting basket (7), a machine base (8) and a machine body (9). The threaded part is detached through rotation of the threaded part, the clamping jaws of the clamping mechanism are closed through the dead weight, and clamping of the threaded part is achieved. The threaded parts slide into the collecting basket through the connecting rod mechanism, and automatic collection is achieved. According to the threaded part dismounting equipment, a grabbing clamping jaw and a collecting mechanism are additionally arranged to achieve automatic dismounting of a sleeve. Labor intensity is reduced, production efficiency is improved, and staff reduction and efficiency improvement are achieved.

Owner:LIAOSHEN IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com