Printing and dyeing method of polypropylene non-woven fabric material

A polypropylene non-woven fabric and printing technology, applied in dyeing, textile and papermaking, etc., can solve the problems of difficulty in dyeing, unsuitable for polypropylene applications, lack of polar and functional groups in polypropylene fibers, etc., and achieve low-cost operation and methods. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 0.25g of Disperse Blue, Disperse Red and Disperse Yellow, add 7.5g of self-crosslinking adhesive, add water to make up the total mass to 50g, stir at 37°C for 10min at a speed of 500 rpm, and make a disperse dye color paste;

[0025] (2) Add 0.5 g of printing thickener to the disperse dye color paste, and stir at a high speed to prepare a disperse dye printing paste.

[0026] (3) Spread the polypropylene non-woven fabric on the rubber pad and put the printing screen frame. Pour the adjusted disperse dye printing paste into the printing screen, along the direction of scraping, tilt the rubber scraper, scrape back and forth twice evenly, and then lift the printing screen frame.

[0027] (4) Take out the printed polypropylene non-woven fabric and dry it in an oven at 90°C for 5 minutes;

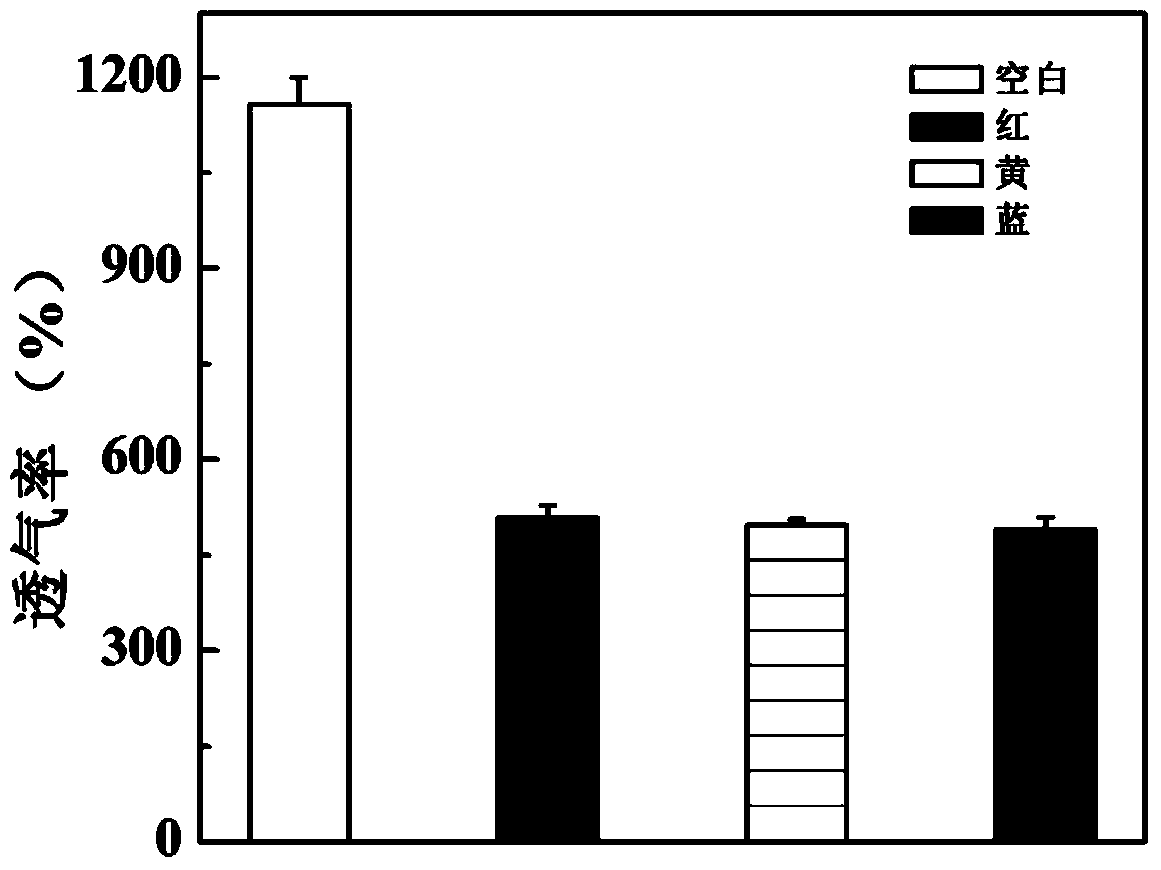

[0028] (5) Cut the unprinted non-woven fabric and the printed non-woven fabric into 200mm*200mm, and test its air permeability with the pressure difference method air permeabi...

Embodiment 2

[0031] (1) Weigh 0.3g of disperse blue, disperse red and disperse yellow, add 8g of self-crosslinking adhesive, add water to make up the total mass to 50g, stir at 37°C for 10min at a speed of 700 rpm, and make a disperse dye color pulp;

[0032] (2) Add 1g of printing thickener to the disperse dye color paste, and stir at high speed to make a disperse dye printing paste.

[0033] (3) Spread the polypropylene non-woven fabric on the rubber pad and put the printing screen frame. Pour the adjusted disperse dye printing paste into the printing screen, along the direction of scraping, tilt the rubber scraper, scrape back and forth twice evenly, and then lift the printing screen frame.

[0034] (4) Take out the printed polypropylene non-woven fabric and dry it in an oven at 80°C for 3 minutes;

[0035] (5) Cut the printed non-woven fabric into 50mm*200mm, and test its dry rubbing fastness and wet rubbing fastness in a rubbing fastness meter;

[0036] (4) The test results are sho...

Embodiment 3

[0040] (1) Weigh 0.5g of disperse blue, disperse red and disperse yellow, add 18g of self-crosslinking adhesive, add water to make up the total mass to 100g, stir at 37°C for 10min at a speed of 1000 rpm, and make a disperse dye color pulp;

[0041] (2) Add 1.5 g of printing thickener to the disperse dye color paste, and stir at high speed to make a disperse dye printing paste.

[0042] (3) Spread the polypropylene non-woven fabric on the rubber pad and put the printing screen frame. Pour the adjusted disperse dye printing paste into the printing screen, tilt the rubber scraper along the direction of scraping, scrape back and forth four times evenly, and then lift the printing screen frame.

[0043] (4) Take out the printed polypropylene non-woven fabric and dry it in an oven at 90°C for 1 min;

[0044] (5) Cut the printed non-woven fabric into 40mm*100mm, and fit it with the wool lining, and test its washing fastness in a soaping fastness tester;

[0045] (6) The test resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com