Injection molding method of glass fibers orientation in orienteering plastic part

A glass fiber and directional control technology, applied in the field of injection molding of plastic parts, can solve the problems of little practical value and achieve the effect of enhancing various performances, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following resin-based glass fiber materials are purchased from Changhong Optoelectronics Company, the glass fiber content is 20wt%; the reduced iron powder is purchased as fine powder with a particle size of 10-44 μm, and the addition amount is 5-15% of the mass of the glass fiber; the viscose The mixture is a hot-melt adhesive composed of thermoplastic resin, and the addition amount is 10-20% of the mass of the resin-based glass fiber material.

[0027] Process example:

[0028] (1) Mix resin-based glass fiber material, reduced iron powder and binder uniformly to prepare injection molding raw materials. Wherein, the glass fiber in the resin-based glass fiber material is a short fiber, the fiber diameter of the short fiber is 9-13um, and the chopped length is 4.5-6mm.

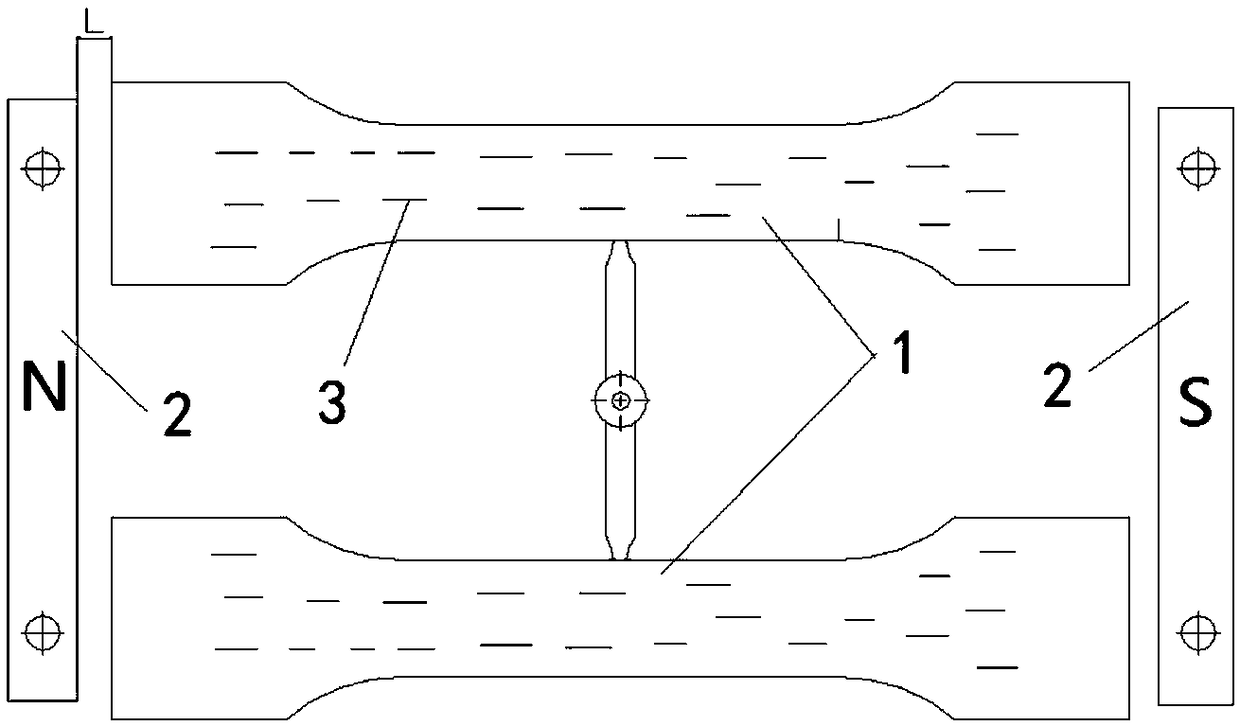

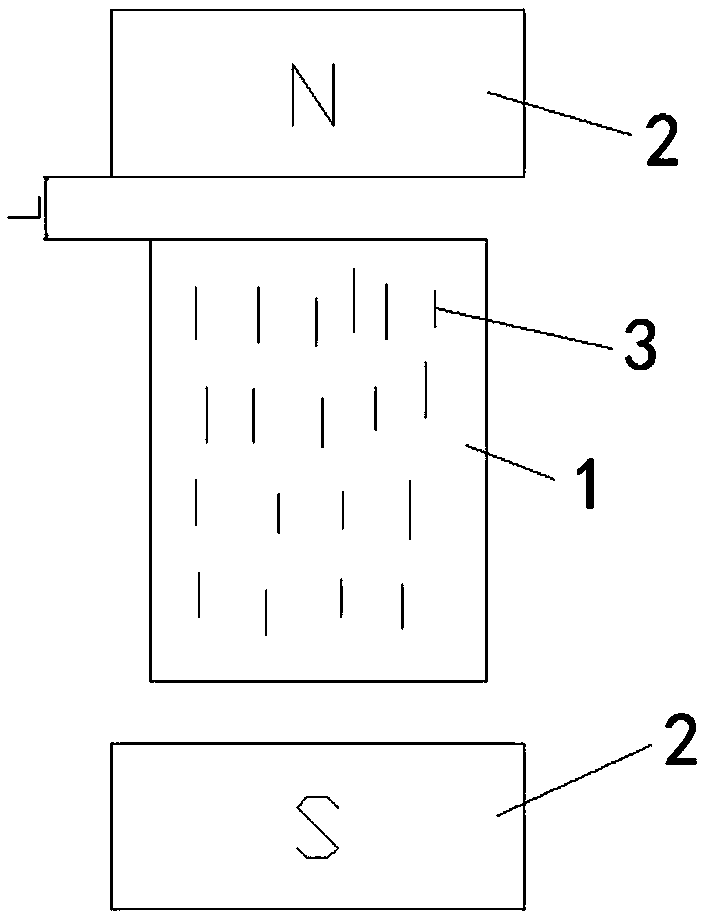

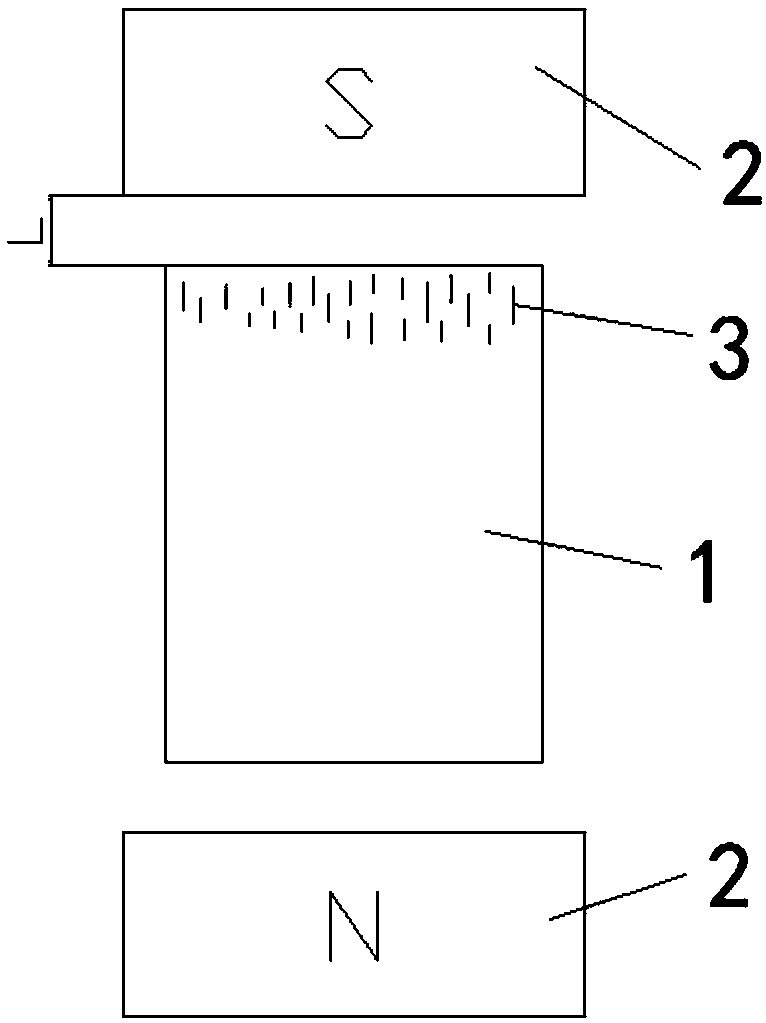

[0029] (2) Based on the set fiber orientation, permanent magnets with N poles and S poles are respectively arranged at the corresponding positions on both sides of the cavity in the injection mold, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com