Method for improving oil removing efficiency of oil removing bacteria

A kind of efficiency and seed technology, applied in the direction of microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of reduced oil removal efficiency and the influence of environmental factors, and achieve good results, small magnetic field strength, The effect of enhancing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

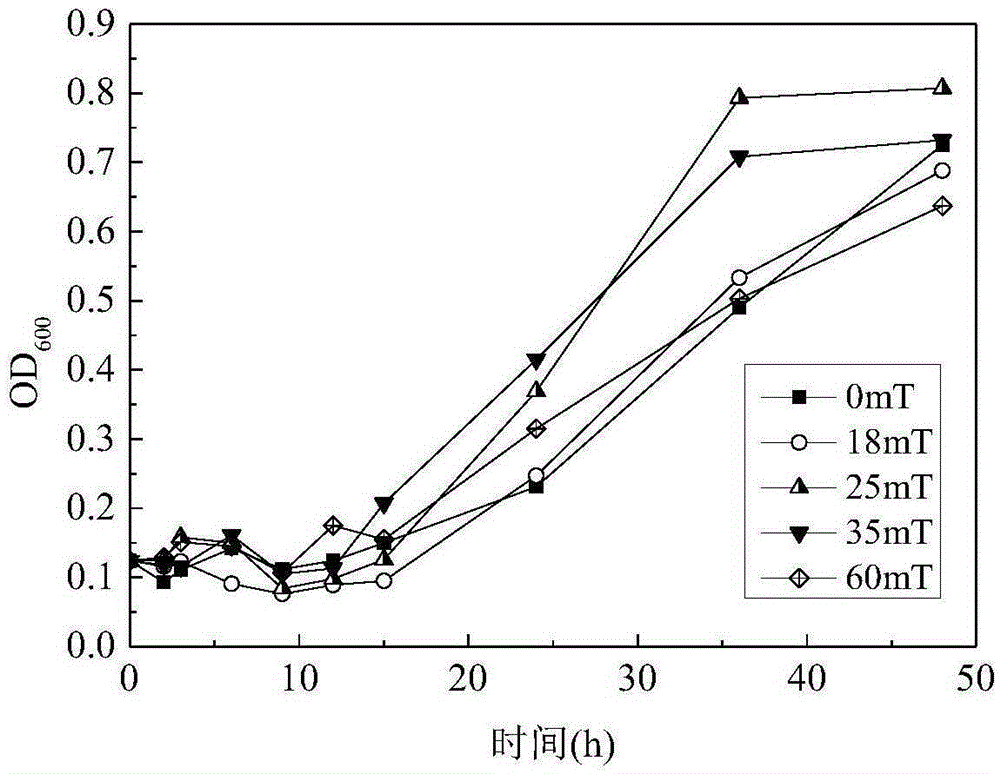

[0049] Embodiment 1: the influence of magnetic field on the growth of degreasing bacteria

[0050] Take the Acinetobactersp.B11 bacteria stored on the slant of the culture medium at 4°C and spread it on the nutrient agar medium plate. After culturing at 30°C for 24-36 hours, pick a single colony and inoculate it into the seed liquid medium, shake it at 30°C and 200r / min Cultivate for 12h. Measure the concentration of the bacterial suspension at OD600 wavelength and dilute the bacterial suspension to 0.8, and use it as a seed solution. According to the inoculation amount of 5%, the strain seed solution was inoculated into the degradation medium of 200mg / L petroleum concentration. Add magnetic fields of 0, 18, 25, 35, and 60mT respectively, and use the blank culture medium without inoculation as a control, and culture it on a shaker at 30°C and 100r / min for 7 days. The results are shown in figure 2 . Depend on figure 2 The experimental results show that the adaptability of...

Embodiment 2

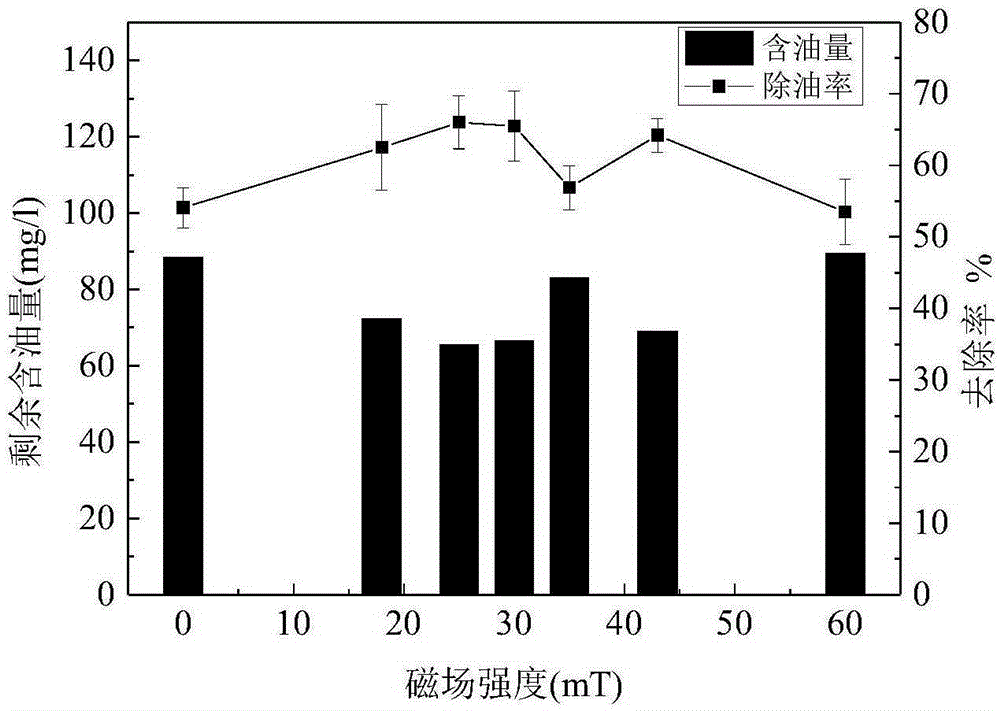

[0051] Embodiment 2: the influence of magnetic field strength on degreasing effectiveness of degreasing bacteria

[0052] Take the Acinetobactersp.B11 bacteria stored on the slant of the culture medium at 4°C and spread it on the nutrient agar medium plate. After culturing at 30°C for 24-36 hours, pick a single colony and inoculate it into the seed liquid medium, shake it at 30°C and 200r / min Cultivate for 12h. Measure the concentration of the bacterial suspension at OD600 wavelength and dilute the bacterial suspension to 0.8, and use it as a seed solution. According to the inoculation amount of 5%, the strain seed solution was inoculated into the degradation medium of 200mg / L petroleum concentration. Magnetic fields of 0, 18, 25, 35, and 60 mT were applied respectively, and a blank culture medium without inoculation was used as a control, and cultured on a shaking table at 30° C. and 100 r / min for 7 days. The effect of microorganisms on the oil degradation efficiency under ...

Embodiment 3

[0053] Embodiment 3: the influence of magnetic field on anti-shock load of degreasing bacteria

[0054] After activation, the oil-removing bacteria were inoculated into fresh liquid petroleum medium, and cultured on a shaker at 30°C and 100r / min for 7 days under the condition of 25mT magnetic field strength and no magnetic field, and the initial oil concentrations were 100, 200 , 500, 1000, 1500, 2000, 3000mg / L. The oil degradation rate and biomass were measured respectively to investigate the effect of initial oil concentration on microbial oil degradation rate and the strengthening effect of magnetic field on microbial oil removal rate at different initial oil concentrations, and determine the most suitable microbial oil degradation concentration. The degradation results of microorganisms under different initial oil concentrations are shown in Figure 4 . The microbial degradation rate of oil showed a trend of first increasing and then decreasing with the increase of initi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com